1/32 Scale MB 326 Scratch Build Part 4

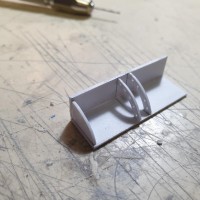

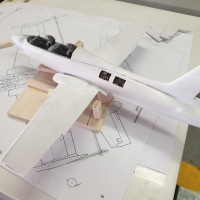

Here we go again, here are a few progress pictures for you guy's, finished the cockpit, scratch built the wings and I made a jig to get the wings positioned properly. I also made the intakes and installed them.

I then decided to add some inspection panels and add detail for the interiors.

The wing tip tanks have been scratch built and will be installed this week end.

I hope you are enjoying the build so far, and please message me if you have any questions or suggestions, or If you would like for me to be more descriptive with the build, please let me know.

Please take care of yourselves and Family during this trying time.

Marc

Wow. That's real artisanship on display there, amazing work!

Thanks for the comment Robert.

Fantastic... Love the art work behind the inspection panels!

Thanks for the kind comment Andrew.

That really is astounding work.

Thanks a mil Bryan.

This is amazing work, Marc! Cannot wait for the next installment.

All the best!

Thanks for the comment, yes, I will be putting in some build time this week end.

What can I say Marc apart from Wow ! I'm interested how you manage to bend so successfully those little copper tubes behind those wonderful inspection cut-outs. Do you use something inside the tube sections to maintain the round shape around the curve? my attempts usually fail miserably. I know plumbers sometimes use a spring device on complex curves when they're not taking the easy way out and fashioning the curves using different connector angles.

Paul

Hey Paul, thanks for the kind comment buddy, hope all is well with you and the family during this trying time, Paul, I used a thick gauge of copper wire that I bent , not tubing, the tubing always seems to kink when you try to bend it past 45 deg. Its always handy to keep a thick copper wire. Chat soon.

Ha ! That explains it. I'll give it a whirl. All's well over here apart from the tedium, interspersed with occasional bouts of modelling. Hope you're all doing OK down in the southern hemisphere. Stay safe. Paul

Fascinating! Love watching your builds come together - from the brute blocking and shaping to the intricacies of getting the proper angles and connections, and the incredible detail (like the work in those compartments). Masterclass in action! I'll never tackle a totally scratch-build project, but I learn a lot that I can apply to my own small scratch-building attempts.

Hey Greg, hope things are well with you and and the Family Buddy, thanks for the comment, give scratch building a try, its not as difficult as you may think, if I can do it, I'm sure anyone can.

Simply amazing!

Thanks for the comment Robert, nice to hear from you again.

Lovely work Marc! Looking forward to the end result. Go to top of the class!