Here is an update on the F-86 cockpit. The replacement dragon decals arrived in the mail so I am "chuffed" to get on with the Huff as the English say and proceed with the build.

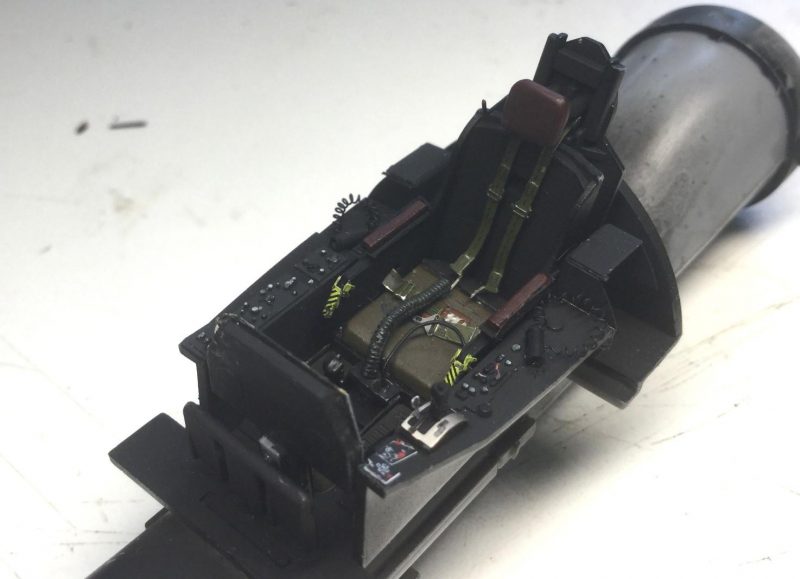

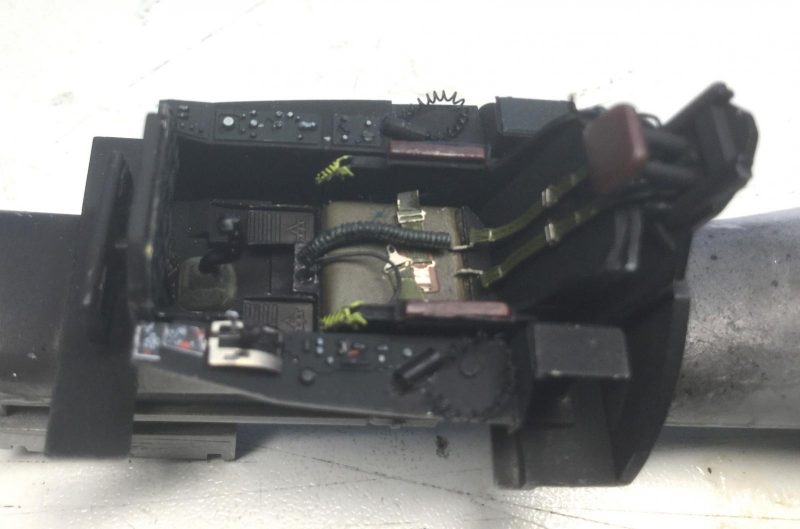

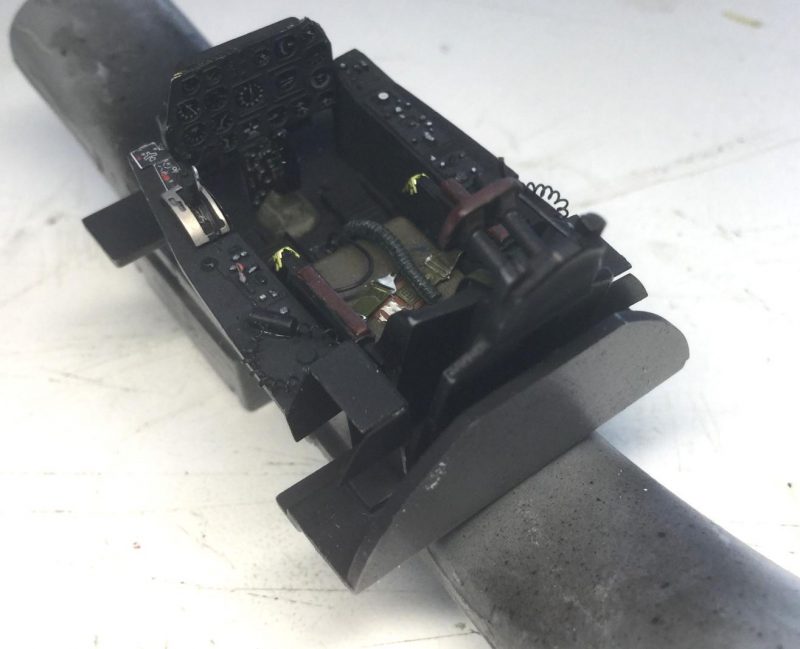

The cockpit has been a challenge, mainly with trying to get a richly detailed look when everything is flat black! I have used a mixture of blacks in masking and spraying console segments, and in repainting some of the etch from grey to black. It is not so visible in the pics but I have used Tamiya Flat Black, German Grey, NATO Black and Life Color Flat Black to highlight details.

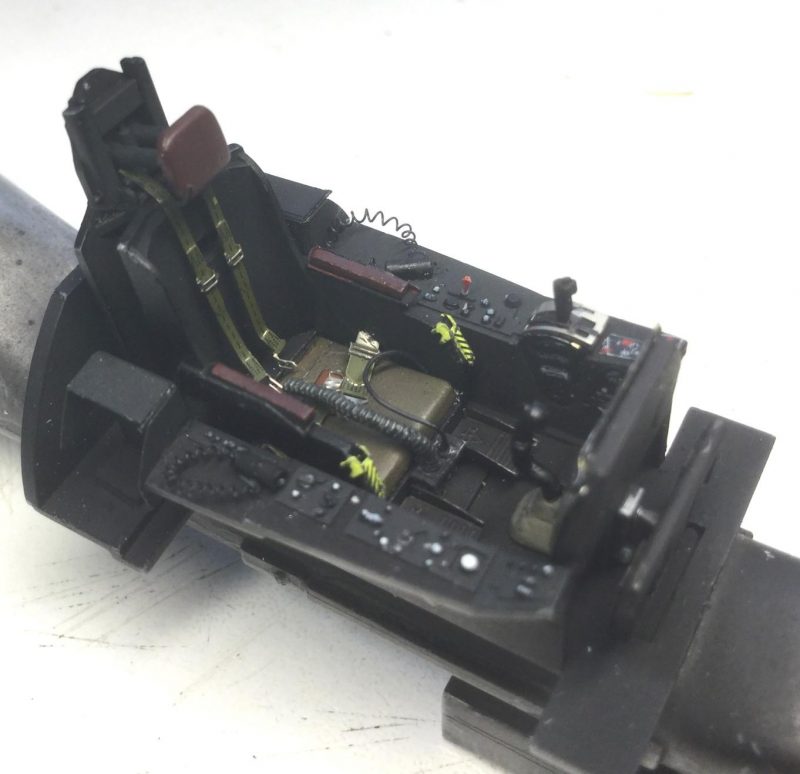

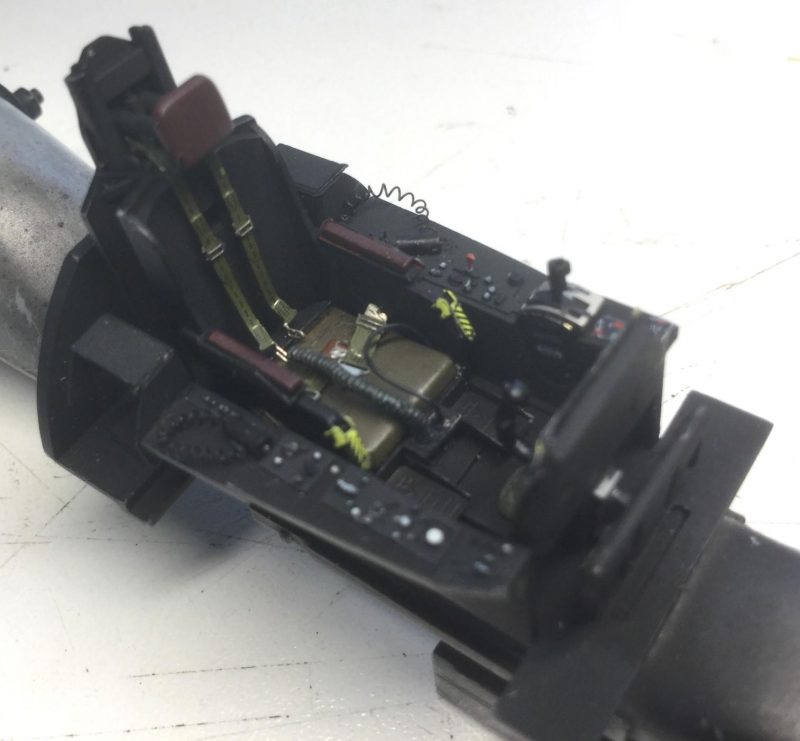

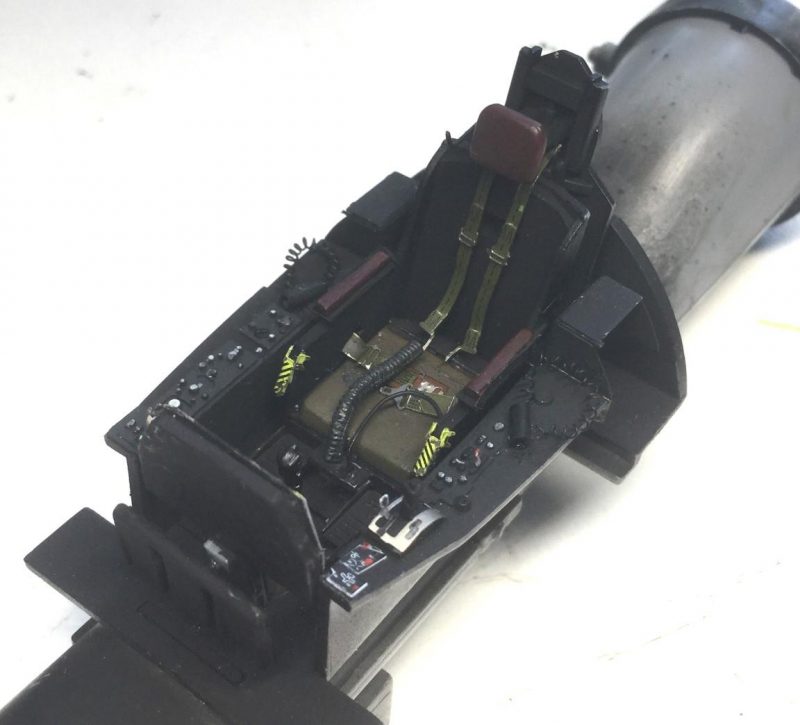

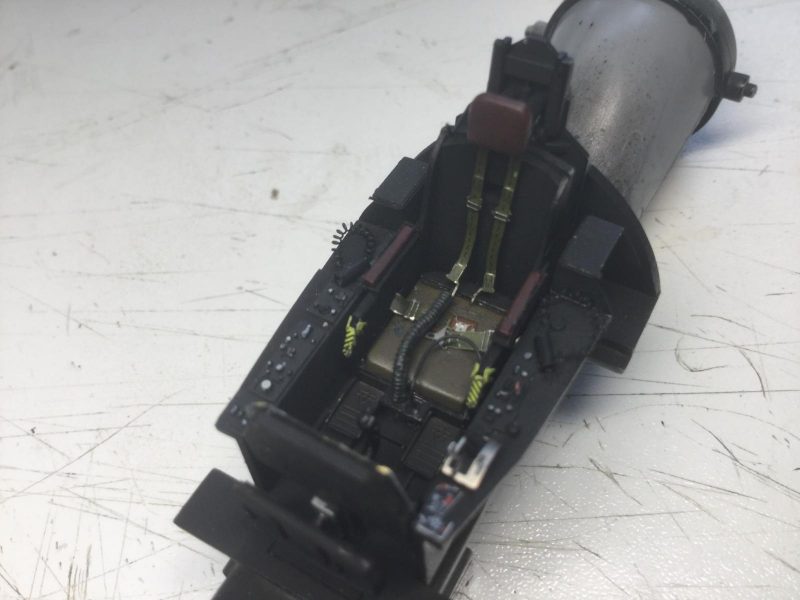

A couple of pics of the seat show added details in the disconnected oxygen hose and radio cable on the seat pad and a seat height adjustment lever from stretched sprue, as well as Eduard etch foot rests.

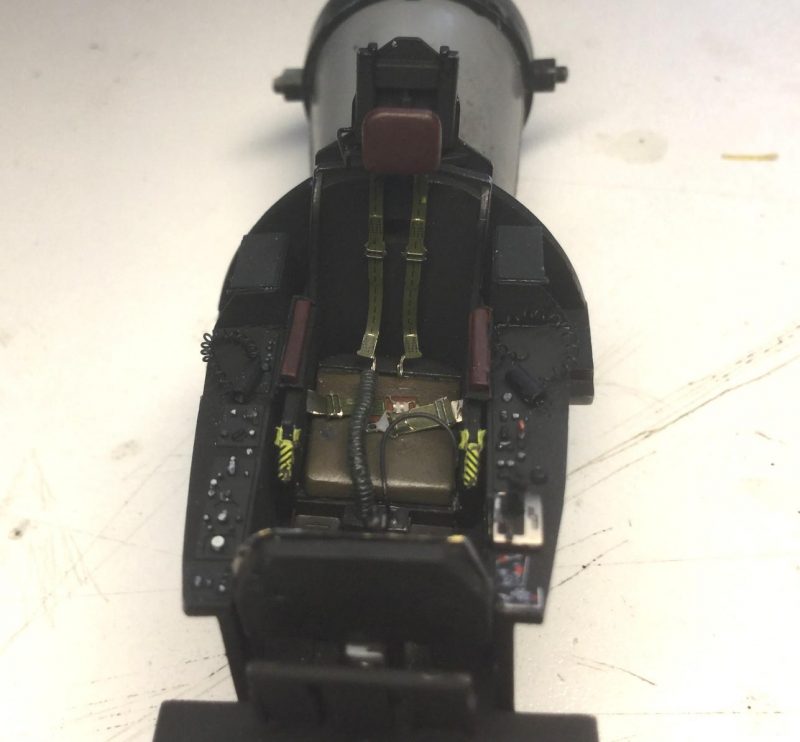

Some pics show the pit without the seat (with scraped paint to glue the seat. Most of the kit switch detail is OOB original and painted with various greys or highlighted with silver pencil. I have added scratchbuilt two cabin lights attached with spiral cord made from wrapping fine stretched sprue around a pin drill bit. The lights themselves are from styrene rod with the ends drilled out. I like the look of the Eduard Color Etch for the belts and harness and yellow/black firing handles. They look good but I nearly had a stroke getting them to stay put with super glue (which, of course, sticks much better to skin than plastic!). Next pics show seat placed in the pit.

-

-

-

-

-

-

-

-

. You may note that the seat is too far back since I just stuck it in there for viewing purposes. I will need to do some trimming of the belt etch ends to get it to fit better. The Eduard inserts for throttle quadrant really help to improve the realism of the pit, even if I had to repaint them slightly with black over grey. Likewise for the set footrests, rudder pedals and instrument panel. BTW, I experimented with 3 different shades for the headrest, based on research showing the headrest could be OD, red-brown, red, black or a light grey. I was initially going for red but i didn't like the look of it against the black and how it clashed somehow with the green details. OD looked too similar to other details but red-brown, which I found in a variety of pics of Korean War F-86 cockpits, looked harmonious. It also happened to be the color in the Hasegawa color suggestions fro the instructions.

-

-

-

I have fitted the pit so far in the fuselage to make sure it all looks OK and doesn't cause closure issues. The fit is so tight on the Hasegawa kit that I may have to trim away bits of etch invisible to the eye - especially where the belt ends make it hard to fit the seat.

There is, of course, more to add with the reflector gun-sight, rails for the canopy and all the canopy detail already done. This will be finished after gluing the fuselage halves together. Stay tuned. Thanks for looking.