Hi, Erik (@airbum). The Cameo and the Scan and Cut are relatively inexpensive compared to laser cutters and the like. For me, they are actually free since I borrow them from my wife. I have used both to make masks for both models and for buildings on my trains. I have never tried making anything small, but I have seen my wife cut card stock into small and intricate shapes. I make my own decals using a laser printer when I need to do something small, but the biggest limitation making my own decals is that I can't make white numbers, letters, and so on. The printer just won't print white, but I have seen laser cartridges for printers that will print white. If you are interested in finding out more about the cartridge, go to Micromark online and they carry the cartridges.

I started using masks cut on a die cut machine because I can do more weathering using painted letters and designs than I can do with a decal. I can also create masks to paint white or light colors.

With both die cut machines you should be able to use material like Tamiya masking tape. I used vinyl to cut my masks simply because that is what my wife had. I was in Austin this morning visiting my daughter and her new baby, and she gave me some fairly thin vinyl that is designed to be a mask. I will try it out in the near future. Both machines should also be able to make fairly intricate masks. I think as you get more practice on either machine, then you will be able to make some really intricate stuff. I am doing baby steps now. Both machines can also cut some fairly thick material. I have seen a video where a model railroader used the Cameo to cut out the plastic walls for a scratchbuilt building he was making. I have personally cut out some chipboard (a type of stiff cardboard-like material) on the Cameo without problems.

The main problem with the Cameo is that you have to manually adjust the blade for the depth of cut and speed of cut based on the materials you are using. You get scrap material if either is wrong, and some of the adjustments are simply trial and error. I went through a lot of masking material before I was able to get a usable mask. It was very frustrating. Her machine is a couple of years old, so they may have new features that will make these tasks easier. You also get a design program with this machine which you can use to make your own designs.

The Scan and Cut has a lot of user-friendly features. First of all, when you put the material you want to cut into the machine, it tests the blade on it and pre-sets depth of cut and speed. So no guessing. I don't know if this is a feature only on the model that my wife has, or on all the models. It makes very clean and precise cuts. The best feature, in my view, is that you can scan something into the onboard program and it will cut it out. So, conceivably, you could print out the letters and numbers, or insignia, that you want cut for masks, scan the prints into the machine, and the machine will cut them out. If you need a multi-part mask, say for a US wing insignia, you can scan a design, then designate which edge you want it to cut. And then repeat for the other part of the design. The machine works best when there is a clear contrast in dark and light so that it can clearly identify the edges you want cut. You could also use drafting tools or a CAD program to design your masks then either import them or scan them into the machine and cut them. In the near future I want to try to cut camouflage masks in the machine for either British or German WW2 camo. You can also re-scale things in the machine. I think it is very versatile and easier to use compared to the Cameo. You would need to check the features and specifications for the machines you are considering because there are a bunch of different machines, manufacturers, and models, and they all have different features. You might try going to Youtube and see what you can find.

4 attached images. Click to enlarge.

-

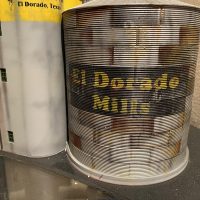

1. Mask cut using Scan and Cut for this building for my train layout.

2. Letters are about a half inch tall.

-

1. Mask for letter printed on Cameo. A little less than a half inch tall.

-

1. Mask printed on Cameo for ID numbers. Plane is 1/32, so numbers are fairly big.

-

1. Mask for lettering printed on Scan and Cut. A little less than a half inch tall.