While this one will not qualify as homebuilt, it does fit into the Air Racing category on the European side of the pond. So to try to bring a bit of life back into this group, here we go!

Messerschmitt Bf 109 V-13 speedrecord plane

Having had a few of the Tamiya 109E’s in 109Werke this one emerges as a fast plane

The story is very interesting and a bit long, and has been told before. This is of course a build-log, so I shall not tire you with a lot of words on the real plane, as it is easy to find online or in a well-stocked library. Some small bits may pop up during the build.

First, the early planes were most often filled smooth, and so the panellines have to go – here it is in company with tow more of the kits

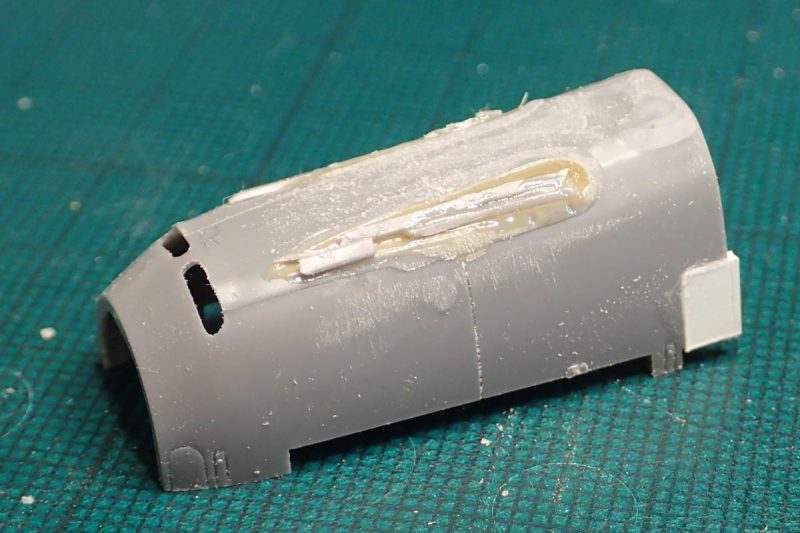

Some Liquified Styrene (LqS)

read how-to here is used as it will ensure a strong non-shrinking bond – what a mess

First, a lot of filing and sanding took place

-

1. These decals are for an earlier version of the same machine.

And some more LqS – then filing, sanding, repeat until satisfied.

The intake were quite different from the Emil base-kit, and a lot of LqS and off-cut parts were used to smoothen things (in the light of experience I should just have used a piece of sheet-plastic)

-

1. Plastic sheet next time!

-

1. Gunthroughs to be faired flush

And the parts so far – the wing bulges were addressed in

my “Messerschmitt Bf 109 Werke” here on iModeler!

next up some more on the intake