I made a list of problems and inaccuracies while I was going through the C kit, which I will go through in that kit's article (which will eventually be posted here) and there are a lot of commonalities of errors with the B/D/N kit as well. I'll just touch on a few of them here:

-The open afterburner cans are mirror smooth on the inside. That's unacceptable, so I'll be replacing the entire assembly with Aires resin.

-The closed afterburner cans have little raised triangles on the inside, which is also unacceptable.

-The instructions have you build the main gear doors open, as if they droop as the hydraulic pressure bleeds. This is incorrect: the main gear doors are physically locked shut unless the gear is being cycled.

-The elevons, however, DO droop when there isn't any hydraulic pressure, so if your plane is "off" they should be drooped.

-The 2000B/D/N kit doesn't give you an ASMP, which is like giving you a pastrami sandwich without any pastrami. So I'll have to source an ASMP elsewhere.

-The B/D/N kit gives you three vertical fins to choose from, but the B uses the same fin as the N, which means you have two D fins. uh... thanks?

-

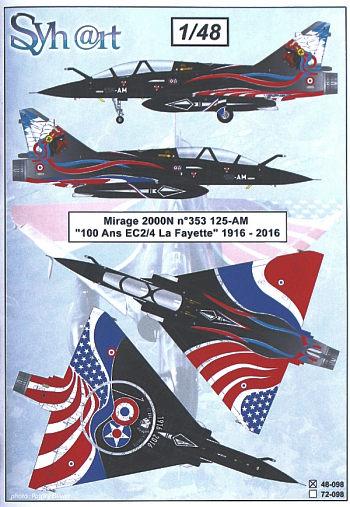

I chose the Syhart n°353 125-AM "100 Ans EC 2/4 La Fayette" 1916 – 2016 bird because the majority of the plane where much of the filler and reshaping exists is gloss black, masks and masking application instructions are provided, and the only part of the livery that involves blending or gradation is in the rear and largely covered up by decals. If this is going to be a battle, then I will give it such a battle as to be worthy of rememberence!

Nasty ejection towers. These and pin marks are common all over the place. Out comes the dremel...

Now, the first half of my biggest headache from the C kit: there's Terrible, Horrible, No Good, Very Bad engineering with regards to the join between the fuselage, upper wings and intakes.

See that gap? That's with the wing halves perfectly aligned. The problem is with the fuselage. You can do like I did with the C and try to fill it with every single filler material you can think of, which means you will obliterate those big bolt heads. The bolt heads are there on the real thing, so you CAN'T lose them.

Here's how to fix it:

Cement the lower wing and forward under-fuselage plate into place. Take whatever steps are necessary to reduce the step in the joint between the rear of the lower wing and the fuselage. The only place you should have cement are this rear joint between the lower wing and fuselage, the joint between the lower wing and the forward plate. Cement one of the top wings into place but use no cement between the fuselage and the wing joint. After the top wing has dried, use your finger to provide positive outward pressure so the fuselage meets the wing. NOW you may cement it in place. Alternatively, you can use small dots of cyanoacrylate glue and an accelerator to tack it into place, and then flood the joint with cement. This is entirely the fault of the fuselage halves bowing inwards. You can't really use a section of sprue to spread the fuselage halves apart here, because doing so will foul the insertion of the engine and afterburner. But it can be done!

The same bad geometry affects the joint between the fuselage, the intake halves and the wing assembly.

But that's another post. Ughhhhhhh whyyyyyyyyy