Everyone has talked about the wings being twisted and bent on the Pro Modeler Ta-154. Mine was no exception. I went about fixing things a little differently. Since this is supposed to be the worst part of the build, I wanted to take care of it first. Some take the plastic and submerge it in hot water to remove the twists. I'm sure it works out OK. Others have added wooden sticks or even metal wire to keep the wings straight.

Here's what I did. I must warn you, this might not work for everyone. If you try this and it makes a mess of things, don't say I didn't warn you. This all happened by accident by the way...

Having said that, here is my "disclaimer".

I don’t recommend this method to anyone, and extreme caution must be used when doing this wing “fix”. But with some care and luck, you can fix this problem in a matter of a few minutes. Plus you don't have to worry about burning yourself with scalding hot water. It works...

I was holding the upper wing and exerting some pressure on it to see if I could remove the twists. As I was applying pressure, I heard a "crack" and then realized the plastic had broken just behind the engine mount area on the leading edge of the wing. In horror, I thought I had destroyed the part. To my amazement, it actually looked better ! The wing was now almost perfectly straight.

-

1. Notice the cracks in the plastic

2. The trailing edge also cracked.

Not being content to leave well enough alone, I continued and carefully exerted more pressure on the upper wing section. This time I applied force along the rear area where the engine nacelle will eventually be installed. I cracked the plastic here too ! Now the wing was straight as an arrow...

If you look close at this next picture, you can see how the cracked area shows up as a lighter color, almost like a fault line in the plastic. Luckily it didn't go all the way through and remains hidden just below the surface.

-

1. Note the hidden "fault" lines

2. This area cracked too. This is not a panel line.

Next I glued the upper wing section in place against the bare fuselage half. This allowed me to get a nice tight fit with no gaps present. A little sanding work will be needed here, but no filler.

-

1. Nice seam here. No filler required.

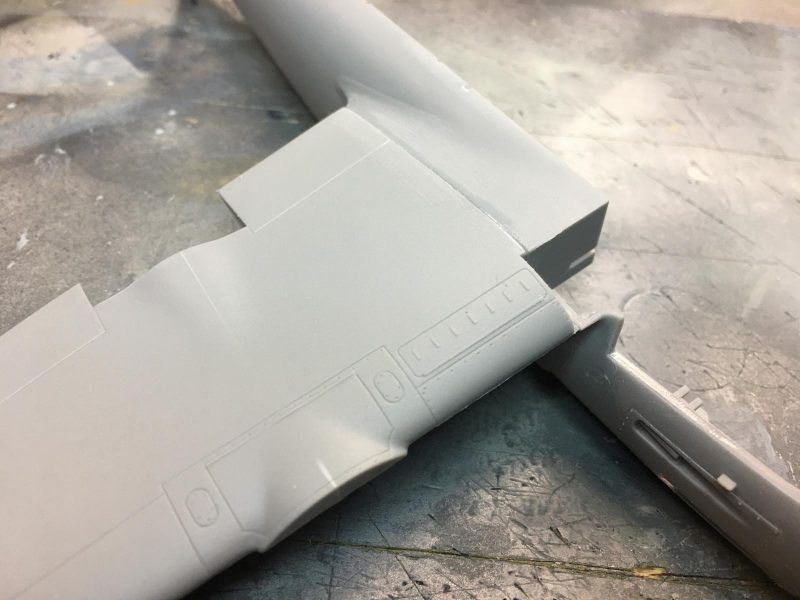

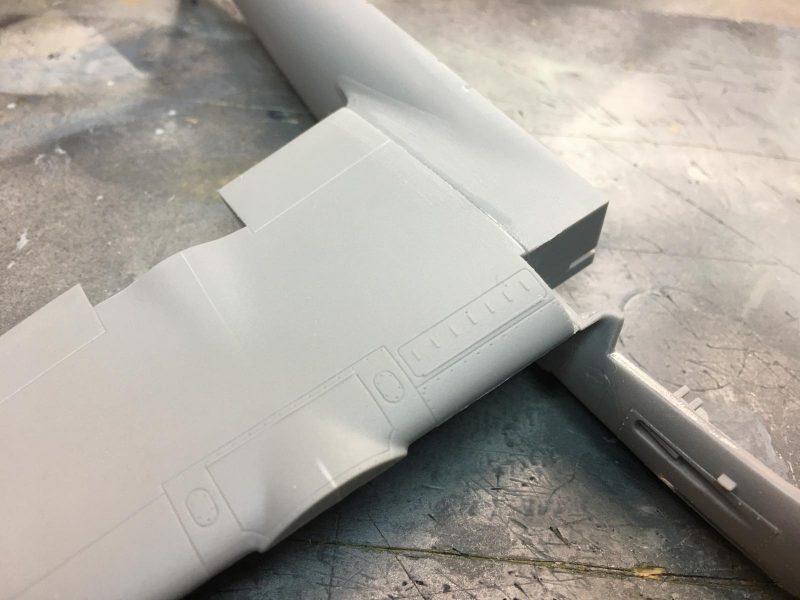

Next I cut off the locating pins and installed the inboard lower wing sections, making sure they fit tightly against the fuselage. I also added the cannon covers. This allowed me to get the fit on the cover almost perfect, since I could work at the seams from both sides.

This was assembly was then allowed to dry overnight.

The following morning I was curious to see how the wings turned out. As you can see in this next photo, they are straight as can be.

I sanded the upper wing joint smooth. It looks very nice. I will leave the line present where the inner portion of the flap meets against the fuselage. This line should be there, so don't try to fill it in.

I built the engine nacelles, and after allowing them to dry overnight, I installed one. I pressed it tightly against the seam of the lower wing. I used liquid glue on the joints. As I pressed it tightly against the wing, some liquefied plastic oozed out. This was exactly what I wanted. You can see how nice the joint lines are. Again no filler is needed if you build it this way.

Since I was on a roll, I installed the outer lower wing panel. The fit was perfect at the nacelle joint. I wanted it to dry straight, so I clamped the assembly and let it sit overnight.

-

1. Note the edges of the wing do not fit perfectly now. There is a very slight overlap here.

There is some very slight misalignment along the leading and trailing edges of the wing. This is easy to fix with a few swipes of sand paper.

Stay tuned for the next installment. This Ta-154 is coming together very fast...