Slow progress on this project just got a bit slower because of one frustrating moment...

Radiator duct

After assembling the fuselage, I went about improving the air intake area, which is such a defining feature of the Typhoon.

The first step was both easy and satisfying. I improved the kit's radiator grille by adding the four spacers supporting the inner and outer circular openings, plus added the two vertical bars to the main radiator. Looking nice and clean.

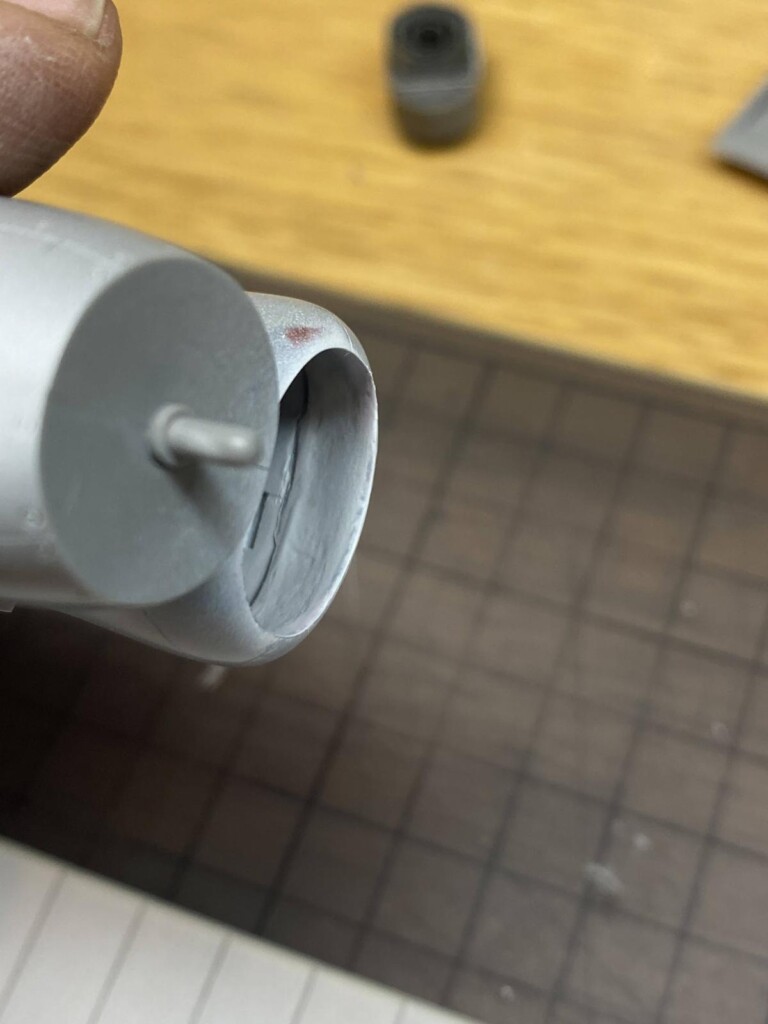

Problem: theses two pics show the fit of the inner surfaces in the air duct. Hmm. One could either ignore the seams, or do something to smooth them out. The latter operation seemed a bit tricky with the radiator in place, but after some deliberation I decided to take the radiator out again and go about smoothing out the duct.

-

1. Radiator removed for the filling & sanding operation. Make sure not to fill this area....

2. The duct inner surface is both short and concave - NOT easy to sand!

The first attempt was to take out the radiator, and then use Tamiya putty to fill in the inner surfaces of the duct, and then try to smooth the surface out using soft brush dipped with thinner. The result was so-so. Sanding would be necessary. BTW, I'm not very fond of using solvent-based putties for surface filling, so here I am way out of my comfort zone!

Sanding was really tedious because the area is so small and short. Care must be taken to preserve v-shaped profile of the upper lip of the duct, and you don't want to apply much sanding pressure to the lip of the intake so that its contour is preserved. I decided to progress really slowly, first cutting down a soft sanding stick into narrow strips, and then using the tip of each strip to gently reach into the area and do some sanding. Sanding, spraying with white Mr Surfacer, and re-sanding turned out to be a very boring task that took many short sessions to complete.

Dry-fitting the radiator. Getting there... I'll paint the inside of the duct dark green before attaching it. Then on to the wing...

If anyone has a better suggestion for how to fill & sand the inside of an air duct, please share!