Time to finish up the lower hull on the M-46.

The final detail is the flange and support housing for the track tensioning wheel. This attaches between the first set of road wheels and the drive sprocket. One on each side.

-

1. Housing attached to hull

2. Road wheel suspension arm

Then the flange is attached to each housing.

-

1. Flange attached to housing

Next to attach the tensioning arm to the housing.

-

1. Tensioner arm attached to housing

-

1. Tensioning arm

2. Drive sprocket

3. Road wheel suspension arm

The front suspension system looks very busy, as this part of the build is complete. Now to paint the road wheels.

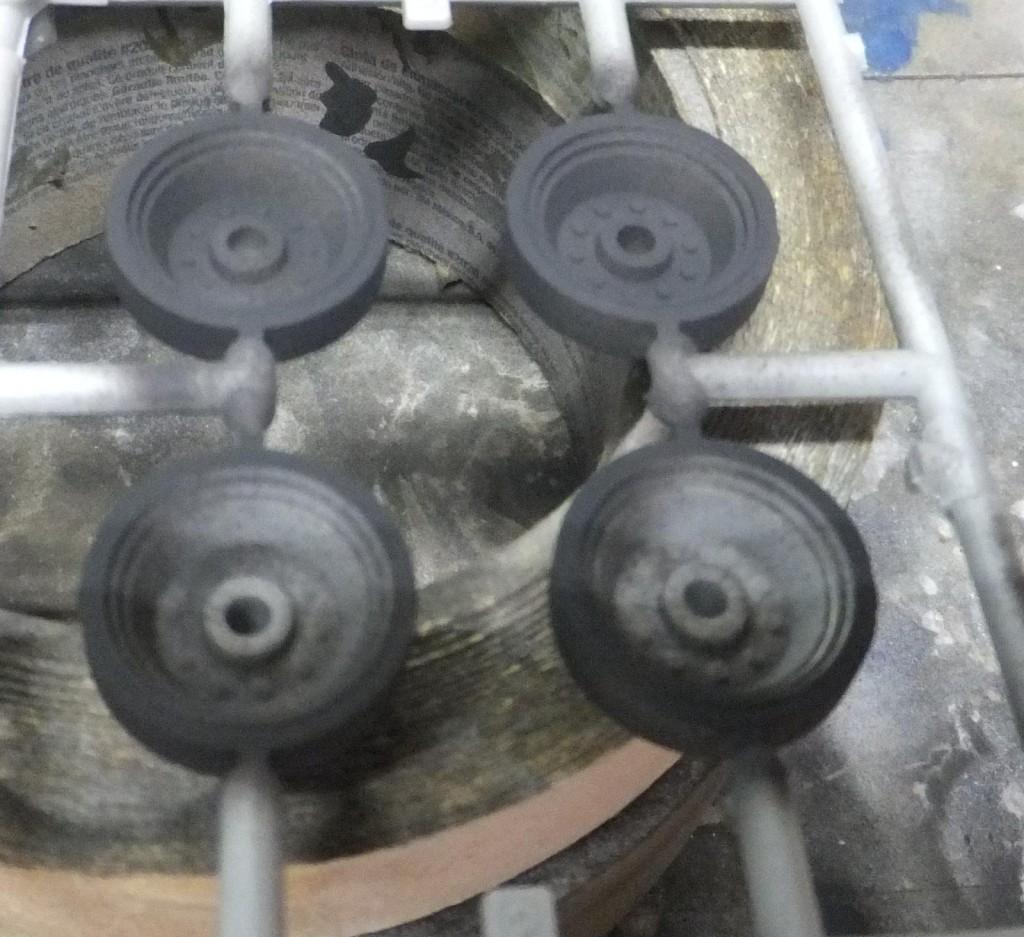

First using Nato black to paint the tires on the road wheels and idlers.

-

1. Tires painted Nato Black

Making sure to paint front and rear sides of the inner and front road wheels.

-

1. Front and back side of Idler wheels

With the Black leftover in the brush, next is to go over the lower hull and paint all the components that are attached as well.

-

1. Nato Black as a base for the OD

It will be easier at this stage to paint this section before attaching the road wheels and tracks. The black is a base for the next step in applying the Olive Drab.

Not a total coverage as this is more of a base color before applying the first coat of Olive Drab. This serves as a base for the next series of OD's.

Now looking at images, it seems to me that a darker shade of OD was used on the tanks used in Korea, comparing images from WWII, taking into account the heavy use, in Europe the fading and environment that may account for the lighter OD's on the US equipment in theatre, compared to stateside service. Regardless I will use Xtracolour US Marine Corp OD to start the base coat on the lower hull, wheels and suspension.

-

1. Xtracolour USMC Olive Drab Enamel

It will dry to glossy finish when dry which is ok, as it will be lightened as we go along. First the USMC OD overall.

It takes a while to dry, but it is quite glossy and dark. I also paint the road wheels, idlers and sprockets.

No I did not mask off the tire section. Though some overspray, but this I can touch up with a brush, which is something you can do with armor. I tried the tedious process of masks, seems like they work well on aircraft wheels, a hassle with armor wheels. So I just paint the hubs then with washes and detail painting with a brush I get the desired result without the use of masking off the tires or wheels.

With the first coat now set, ready to apply the lighter shade of OD over the dark OD/

-

1. See the difference on the Russian Armor Green

Mission Models Olive Drab is then lightly misted over the dark OD.

You can see how the Darker shade under the lighter coat still enhances the details on the hull, bolts and rivets.

The MM OD dries flat. So far the results look what I was after. Yet still maintaining that darker OD shade compared to a WWII US tank.

Next up to install the road wheels.

More to follow