Balancing weighty matters

Every mechanic can tell you stories about aircraft idiosyncrasies. Stories abound about aircraft towing and jacking incidents. I have one about how I severely injured my back lifting the wing of a C-177 RG to change a tire because we did not have a jack available and the aircraft was blocking the taxiway.

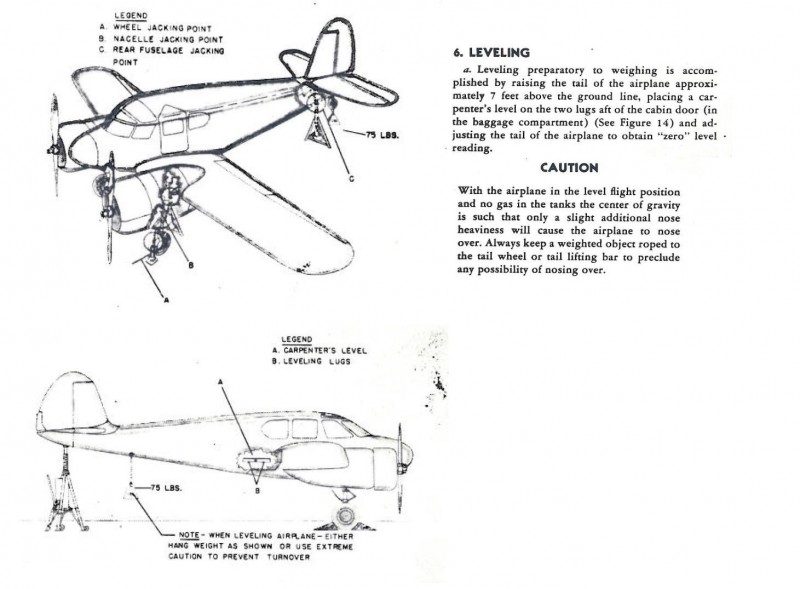

The T-50 Bobcat was no exception. With its light, wood empennage structure and weighty motors well forward of the CG, the Bobcat would stand on its nose if brakes or other controls were misapplied at the wrong moment. This was also true when jacking, as the T-50 in level flight attitude was very susceptible to nose over. This was not a pretty sight with the aircraft five feet in the air on jacks. The answer is weight on the tail and the manual specifies this when jacking.

However, the manual depicts a neat, 75 pound, trapezoidal weight hung from the tail wheel or forward on the empennage. But how many shops have such weights handy? And hanging heavy stuff from fabric covered surfaces can present some problems.

Enter the real world. The common weight used for this purpose is sandbags. In this case, a couple of 35 pound sandbags served the purpose nicely.

As an aircraft mechanic, I get no respect. Yeah. Just the other day my wife said to me, “I thought you told me you worked at the A&P supermarket.” I tell ya, as a mechanic, I get no respect, yeah.

You wanted fifty aircrews!? I thought you said fifty airscrews! http://www.cessnat50.org/media/manuals_and_newsletters/erection_and_maintenance/erection_and_maintenance_183.pdf

Great information, Mr. Ley! Why, just later today I'm scheduled to put a Bobcat up on jacks for this very same balancing procedure! Your cautionary warning hits the mark right on time. I might've forgotten to dredge up some sand from the local river for those needed sandbags. (This is my first time doing this task.)

NIce story & photos, ny friend!

We were way more sophisticated than that in the shop I worked in. We had the sandbags as well, but our preferred method was half a 55 gallon barrel filled with concrete and mounted on casters so we could move it around. A piece of steel pipe was inserted in the center, into which slid a second pipe with a hook welded to the end. Holes were drilled through both pipes so you could insert a pin or a nut and bolt. Put the hook through the tail tie down ring, jack the airplane to the desired height, put the pin through the pipe and there you were. Retractable single engine Cessnas were the worst, because you had to jack them about six or seven feet off the ground so the landing gear would clear the floor when it fell out. I had to do that by myself once. It was not fun. The best jack of all was the factory one that Beech had for their singles and light twins. It was a big triangular affair on wheels that you rolled under the airplane, lined up all the jacking points and then lifted the entire airplane off the ground. No sandbags or concrete barrels needed!

G, it's nice to have another A&P around. And no, I don't need any groceries just yet...

Now that you mention it, I remember the cement filled, half fifty gallon drum solution. We had this in several shops I worked in. It was heavy, but worked nicely. We would roll it around on the edge of the rim at 45 deg. using the pipe as the axle. The benefit was its rigid setup used in place of a third supporting jack. The can was typically painted bright red so mechanics would not trip over it. It returns now to memory in small pieces.

Cessna's SE retract mechanism was an oddball arrangement. It always reminded me of a bird tucking up its legs. The geometric complexity of rotation combined with lateral movement made for some interesting issues. One would have thought Cessna would have learned a lesson from Curtiss.

No doubt you experienced that moment when the gear hit the ground because the aircraft was not jacked up quite high enough. Fortunately the impact was never enough to knock the aircraft off its jacks, but it certainly was enough to momentarily tighten one's sphincter.

The C-177 RG was one heavy bird. In place of a jack, I used my back, standing on my tip-toes, to support the wing while the tire was changed. The next morning I woke up literally hallucinating with pain. It took me three days before I could move to uncurl myself from a ball. Over the years the pain resulted in grinding down my front teeth from nighttime bruxing.

It took many, many years of intermittent, crippling pain episodes before it finally got to a point where it hardly bothers me anymore. It was one of those truly stupid mistakes one makes when they are young and have watched too many cheesy, Hercules movies.

I never saw the Beech jack. It sounds like a support-cradle affair where one jack supported all the jacking points. It also sounds big - really big, and expensive - really expensive. The FBO's I worked for were small - really small, and cheap - really cheap, like that cement filled, half drum solution. Could the Beech jack lift a Model 18?

I suppose an A&P could moonlight at the A&P for groceries.

The Beech jack was a big triangular affair with a single high capacity pump to get the thing motivated. You'd roll it under the airplane, line up the wing and nose jack points and away you went. There was a safety lock so it wouldn't drop the airplane if the pump failed, and you could actually roll the airplane around on it while it was jacked up. The one we had fit the Bonanza, T-34 and the Baron, but was not nearly big enough for a Twin Beech. I can't find a photo of the thing to save my life, but if I do, I'll post it here.

I never had Cessna gear kit the ground, but did have one main on a Skymaster hang up for a second before it fell out and was totally terrified for several seconds while the airplane swayed gently back and forth on the jacks. I was standing on a ladder reaching into the cockpit to cycle the gear lever at the time. They said they never saw anyone move so fast...

You might be an aircraft mechanic if:

You've slept on concrete under a wing.

You've said, "Yeah, it's supposed to look like that."

You've had to defuel an aircraft an hour after fueling it.

You can sleep anywhere, any time, but as soon as the engines shut down, you're wide awake.

You've used a piece of safety wire for a toothpick.

You can tell the difference between avgas, deicing fluid, Jet A, Skydrol and 5606 by taste.

You worked a 14 hour shift to ready an airplane that ended up not flying the next day.

You wash your hands before you go to the bathroom.

You have better bench stock in your coverall pockets than they do in the parts room.

You've used a wheel chock for a pillow AND a hammer.

Your toolbox costs more than your car.

You can throw a wrench farther when you get p****d off than ANY car mechanic.

God created aircraft mechanics so pilots could have heroes, too...

Excellent! I tick all the boxes.

A thought provoking comment. So many of these lines bring back memories; not sure about tasting Skydrol though.

I once owned Cessna's push-me-pull-you, a P337 no less. It was prohibitively expensive to fly and maintain, so after a short time I sold it. I always got a kick out of the rear engine health check that consisted of a small, parabolic mirror mounted on the strut. If you could see the prop, abort the takeoff. Like there's time to watch rear view mirrors on take off. The military version of the Skymaster was so heavy, it would not fly on one engine. As my multi motor instructor once said, "Twin engines just double your chance of engine failure."

As a child of an Air Force father, I grew up with the pervasive smell of 5606, 60 weight, OD canvas, and that quilted insulation peculiar to military aircraft, tickling my nose. I remember people talking about how those old airplane stank. I suppose its all in one's perspective, as to me these were like perfume. Just thinking of those smells evoke strong memories buried deeply within my past.

It's like that time I was taking courses for my degree in diesel maintenance. (That eventually led to a job with Caterpillar and a completely new experience in grease and grime) One of the students was bitching about the foul smell of diesel. Alanzo, our instructor, playfully sniffed the air and said, "Smells like money to me."

Years earlier, before growing accustomed to the smell of agricultural chemical, I gagged upon my initial arrival at an operation with its nearby loading ramp. "Gawd! How can you stand this stink?” I exclaimed, “It’s enough to make you puke!” He looked at me and said quite seriously, “that’s profit you’re smelling.” As I said, smells are all in one’s perspective.

Ever seen photos of this famous aircraft? Ever wondered how this happened?

Here’s the story behind it. https://www.messynessychic.com/2014/04/24/all-aboard-the-flying-yacht-circa-1950/ This is my kind of flyin' and thanks for the mammaries.

Here’s an odd photo, can you guess where it was taken?

And here’s another interesting use for ex-military aircraft

https://www.messynessychic.com/2017/08/03/happy-hour-aboard-an-abandoned-us-military-airplane-in-the-costa-rican-jungle/ Barry Seal would have loved it.

God created pilots so aircraft mechanics would have a job.