@airbum, @fiveten, @johnb,@holzhamer:

Let the Build Begin

I forgot that Hasegawa likes to get the most out of their kits by producing irritating fuselage inserts that raises the difficulty of constructing this Typhoon. If you are building the early Typhoon 1B you get the car door inserts and the late model gets the bubble top pieces. Hasegawa could have made life a whole lot easier if they had just gone the extra step and produced separate early and late fuselage halves with everything molded in place instead of this impending headache.

But no...

Here's the fuselage halves taped together with the starboard bubble top insert already glued in place. One has to take their time here lining everything up while the glue sets or you will be sorry later.

Now here's the port insert taped into place for testing:

-

1. fit is not bad but installing the cockpit may change the whole thing and a piece of thin Evergreen may be needed to fill the potential gap as others have reported.

Now it's time to get out the Mr. Surfacer 500 and a scribing tool. Here's what I'm in for. This is the starboard fuselage with insert glued in place:

-

1. fill this gap and sand

2. fill and stop here.

3. fill and sand

4. sand lightly and rescribe

Here's what it looks like filled with Mr. Surfacer prior to masking off the area to prevent damage prior to very careful sanding.

-

1. this will get cleaned up but molded detail might be compromised.

2. the photo exaggerates the heavy look of the filler

Cockpit

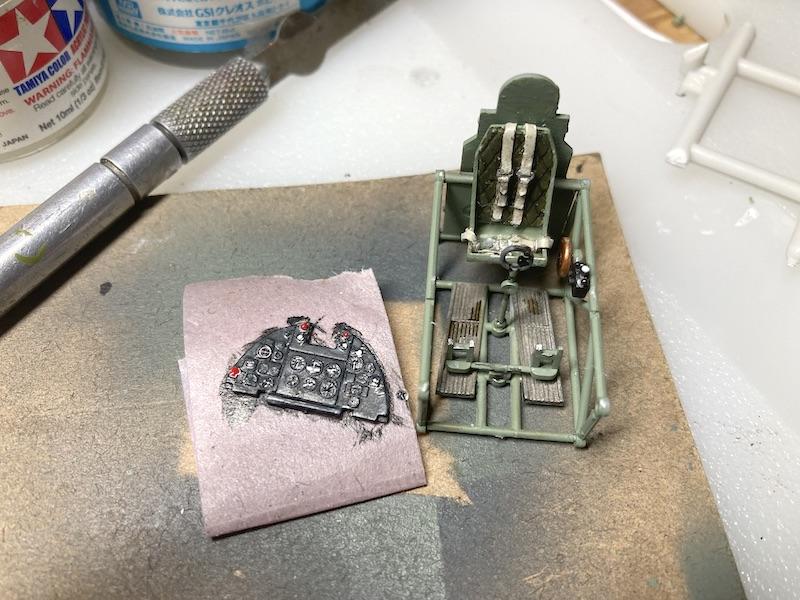

Meanwhile - I did manage to knock out the cockpit which is really awful and all wrong for the most part. BarracudaCast's resin replacement is magnificent but that's another $30 out the door counting shipping and sales tax, so the kit one will have to do.

I used Airscale instrument dial decals right over the raised kit dials. I will set all this assembly aside until the fuselage sanding is done.

-

1. Quickboost seat

2. ejector mark filled and sanded