I've found a new obsession in 3D modeling parts. It really feels like I'm building the model twice. The first time is drawing the 2D art and using that as a blueprint to model the 3D parts and the second will be actually building the bikes after all the parts are generated.

Some may say this isn't "scratch-building" in it's pure sense, but I beg to differ. Creating parts as accurately as I can in the computer from the photos, manuals and memories is, in my mind, pure scratch-building. Plus, the added benefit of learning a new skill. I should be tracking the hours spent on this project, but what's the fun in that?

At any rate, here is the front end assembly with the headlight in place. I played with a front fender, but it's not perfect, so I will re-visit that part later. The free-form building is a real challenge.

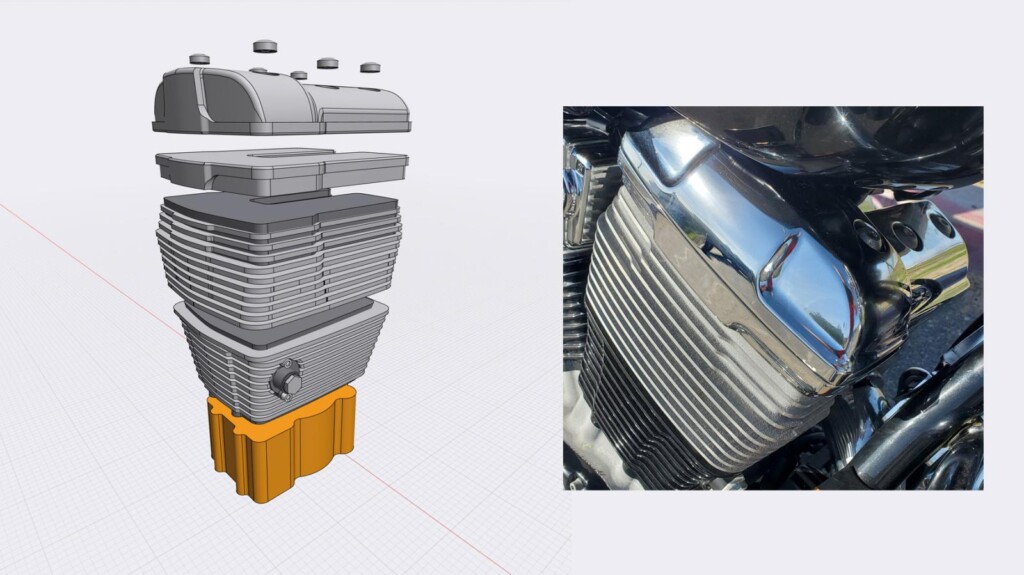

I have moved on to the heart of the beast—the engine. The Super X "X-Twin" engine was an 85 ci, 50 degree v-twin originally developed by Weslake out of England. It was later refined and sculpted into a pretty sexy powerplant. Here we see the raw cylinder without the intake/exhaust ports carved out. As in most of the parts I've created to date, I needed to reverse engineer my thinking to build the parts in a way that the software would allow me to construct the desired end result. After living in the 2D graphic design world for 30 years, this is challenging at times.

-

1. Engine block

2. Jug

3. Head

4. Valve cover - Lower

5. Valve Cover - Upper

6. Cam Chain Tensioner

And finally, me and a fellow E-H staffer at the Laconia New Hampshire Bike Rally, Father's Day 2000. I'm on the left.