Here's tonight's update.

Remember the large single piece of plastic that I replaced on the lower wing section ?

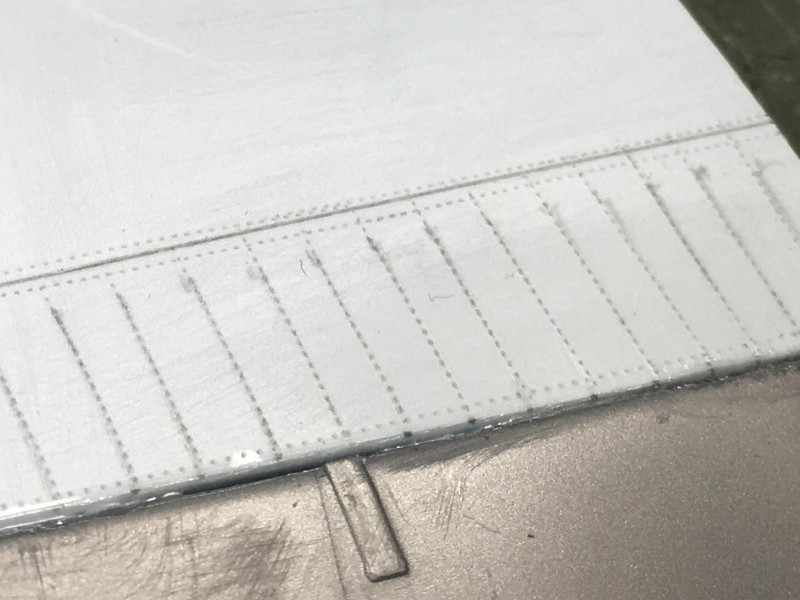

Tonight I was fitting the wheel fairing and this involved some careful trimming of the kit supplied part that I cut off to make it easier to install the new sheeting. I also removed all of the raised panel lines and sanded the wing surface smooth.

This next photo shows how it looks once the wheel fairing was glued in place.

-

1. This trailing edge area is straight on "Witchcraft"

2. I glued the wheel fairing back in position now the rivets are done.

There is a small problem with using roller wheels to scribe on a rivet pattern. You can't carry the rivets all the way up against a vertical obstacle. The rivet wheel hits against the nacelles when it gets really close. (They make a special tool that allows you to scribe the rivets up close in tight confines).

I don't have the tool... so I did it the old fashioned way. I used a pin and simply pressed the individual rivets into the plastic where it was too tight for the wheel to work.

Using the pictures I took of "Witchcraft" as a reference, I laid out some new lines in pencil. Then I went back and using the back of a #11 blade, I scribed the new panel lines.

This is my first attempt at doing this on something at this level...

Are the lines perfect ? Nope... not at all. Are they spot on the money as far as spacing... No, I used some "artistic license" here, since at this 1/48 scale, it would be next to impossible to add all the rivets that are present on the real thing...

This is close enough for me. I have a lot more work to do here. I'm just getting started with the new lines and rivets.

-

1. These small scratches should be hidden under the foil

I am especially happy with how the engine nacelles look now that the ends are open, and there's some plastic sheeting that is more true to the real plane. This is more of a true life representation of the real plane now.

-

1. The real plane is just like this. The wing skin goes under the nacelles.

I also noticed a small problem that Revell did when they molded the wing section years ago. They have the trailing edge of the landing gear opening with a short offset on one end. After studying the pictures I took of the real plane, I discovered this trailing edge should actually be straight.

-

1. Notice the offset in the trailing edge.

2. This end is square on Witchcraft and not pointed. So I cut the excess plastic off on mine.

So I left the sheet plastic straight and decided against cutting the offset into it... I can't wait to get scratching the details on the gear wells next.

I'll post up a few pictures showing what I'm talking about soon. It's getting late here and tomorrow is a busy day.

Thanks for stopping in, and as always, comments are encouraged.