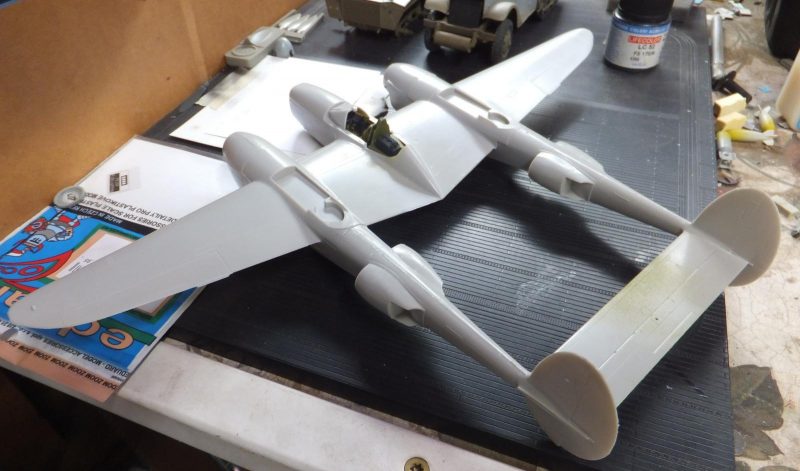

Now that moment in installing the booms on the P-38.

The center mounted horizontal stab.

Before assembling the nose, a pair of lead sinkers were placed in the nose.

Most of the details are left off the boom for now, no gear, intake scoops and side scoop doors. The LH boom is loosely placed on the wing.

-

1. Not set in place yet

2. Already a gap to contend with

Next to set the RH boom in place, not glued in yet, the center horizontal stab is then placed between the tails but not inserted as yet.

-

1. Both booms are still loose

2. Center stab ready to insert into one of the booms

Now I glue the center stab in place in both tail booms.

-

1. Horizontal stab cemented in place

Some nasty gaps first appear before the booms are cemented in place on the wings. Especially around the rear attachment join to wing. Some adjustments for better fit is made before final glue application.

The outer lower wing panels fit very well to the outer join to the boom.

Next is to drill out the landing lights on the lower wing panel.

Not very careful being that I ended with a bit of a chunk of plastic breaking off at the edge. More cleanup time on my part. Any added the clear lens after apply some Chrome on the back side.

Finally the outer horizontal stab panels are attached to the tail booms.

Next up add the details to booms.

More to follow.

1 additional image. Click to enlarge.