Howard DGA-6 build Completed

After deciding on a building strategy, a test fit of the fuselage halves and wing gave me some idea of how to install the frame members that can be seen through the windshield. Those parts were also were cleared of flash and the raised lettering outlines removed.

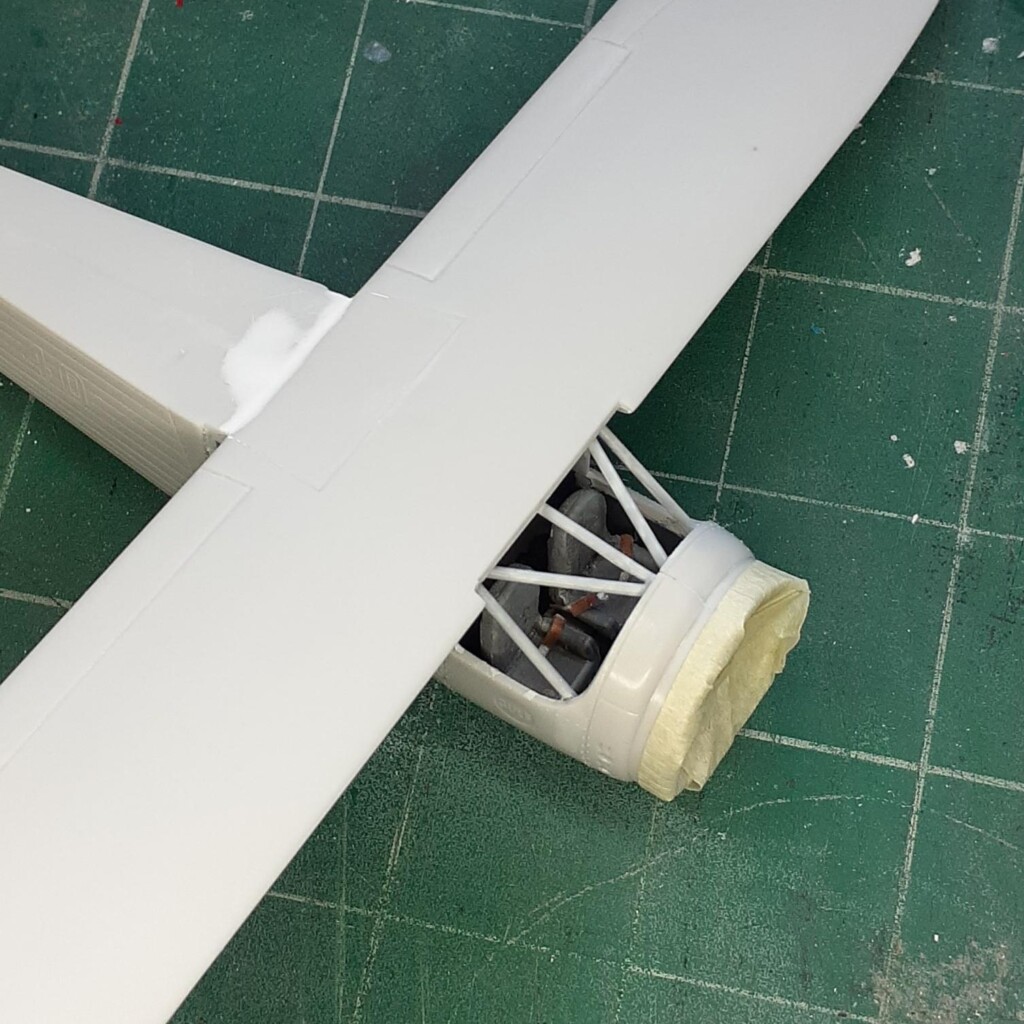

The fuselage halves were taped together to determine where a disk of .020 styrene could fit as a firewall and mount for the instrument panel. Using a pair of calipers, the diameter was measured at 7/8 inch. Some material had to be removed on the inside, particularly around to locating pin and socket. Once the disk fit well, the cowl/engine piece was test fitted. That fit was reasonable, but the 1/16-inch-thick trailing edge became noticeable. The engine facade was removed by a rotary tool, which was also employed thinning the cowl, followed by some light sanding. The spare engine from the parts bin dropped into place within the cowl. That meant that disk in the cockpit was only needed to support the instrument panel.

Inside each fuselage half is a molded mounting bracket for the bench that the pilot figure sits upon. These were also ground off. The socket for the landing gear fairing were used as a tab to glue the new cabin floor in place. It took constant test fitting and two iterations to get the correct shape for the floor. Finally, there was something to glue together. Once again, the fuselage halves were taped together, this time with the disk in place. The floor was inserted through the windshield opening and glued to the right half.

Also in the parts bin was a sprue fragment of seats. Two were removed and strips of HO scale 4 X 8 (.043 X .090) styrene were glued to the bottom to elevate them. Neutral gray paint was brushed on and a black wash applied in the cervices. When they were dry, seatbelts fabricated from card stock were added, then glued to the floor.

Instead of fabricating an instrument panel, one was painted on the disc with two-tone gray and dials marked with a felt tip pen. Brass rod of 1mm was wrapped around a small screwdriver shank into a horseshoe shape to serve as control yokes. A rod was glued across the back side of each, followed by a disc punched out of .020 styrene to simulate a hub on the front. Once painted black, they were glued into place.

A two-tone interior was applied by brush. The instrument panel was added and the fuselage halves glued together. Seams and sink marks were filled and sanded. Unfortunately, no longerons are molded on the topside. I didn't bother with that detail and went with the flat surface. The kit has a spreader bar between the wheels. Photos show that this is incorrect. Instead, V-shaped bracing was employed. Holes in the fuselage were drilled for that rigging as well as in the fin and stabilizers.

Next, the wing was glued on, followed by addressing the seam at the top of the fuselage.

Before installing the frame members behind the windshield, a test fit of the clear part revealed a poor fit. After careful filing and sanding, it eventually settled into place, but with gaps at the top and bottom of the windshield and it rested proud of the fuselage aft the wing. The frame members were cut to length from 3/64-inch styrene rod, which might be overscale, and then painted light gray.

Rather than install the clear part after painting, it was installed next and putty was used to fill the gaps. Unfortunately, blobs filler could be viewed at the top, so they were hidden by not masking them and be covered by paint.

Moving to the landing gear, the sockets for the spreader bar in the spats were filled and holes for the wire drilled. The spats were glued together and then to the struts and each assembly attached to the fuselage.

Even though the notches in the wing strut fairings are too deep, they make it easy to glue them in place. Filling and sanding around this area proved to be a challenge and I was unable to get a good result. I did notice in photos that secondary bracing struts were attached to the main struts. Using a pair of dividers and the underwing registration number decal, their placement was identified. The dividers were next used to determine the length of airfoil stock to cut. With those in place, it was time for paint.

Paint and Markings

A rattle can of automotive light gray primer was used for the first coat. That revealed more filling and sanding was required. Another quick primer coat and then a coat of Tru-Color Insignia White slightly thinned and r******d. After that set up, a gloss coat, also with retarder followed.

Decaling was straight forward, although, because of the carrier film around the printing, it was a little difficult to align the fuselage decals with the raised boarders. A bit of Micro-Sol got them to settle down nicely.

Using a twisting motion with a narrow tipped felt pen, the exhaust stubs were darkened. A dark wash was brushed into the hinge lines on the underside control surfaces. The wash was inconsistent, so on the top side, the backside of a knife tip cleaned the lines. I liked the result so much that I dispensed with the wash.

Final Construction

The glazing was unmasked and, unfortunately, some bleed occurred at the lower edge of the windshield. Attempts to scrape it off were unsuccessful, so it was left alone (*%$#!)

The tail was rigged with thread and painted steel. Two segments of .015-inch music wire served as the landing gear rigging, then the wheels inserted into the spats. The engine was glued into the cowl, making sure that cylinders align with the bumps, then glued onto the fuselage.

As per my custom, the prop was the final piece.

Conclusion

So, was this a quick and relaxing build? Not as quick as I initially thought. Was it a fun build? Absolutely!

Parts fit is generally good after cleaning up and their low number kept things simple, which did, however, sacrifice accuracy. The DGA-6 is a handsome aircraft and this kit produces a likewise model, although I suspect the fuselage height should be greater to create a steeper slope in the windshield. It is also a good ride to use going down a “more accurate” rabbit hole. At the very least, an aftermarket engine plus seats should be used in any build of this kit.

If I were to go all the way to the bottom of the hole, I would also;

• Scribe an outline of the cabin door on the right fuselage half.

• Fill the trenches for panel lines and re-scribe them.

• Use the smallest diameter half-round rod stock to simulate stringers at the top of the fuselage. The sink mark there would be filled with a slurry of sprue runner segments dissolved in liquid cement first. After using liquid cement to attach the rods, I would brush coat more cement over them to blend into the fuselage.

• Sand the rest of the stringers to match the top.

• Remove all of the decal locators.

• Remove the rear most frame segment for the glazing so that it would fit flush.

• Install shims to fill the gaps at the front of the windshield.

• Also use shims to make the wing struts fit better in their fairings.

• Build up a fairing on the bottom of the fuselage for the landing gear bracing wire.

• Also create fairings around the wires at the spats.

• Create navigation light lenses.

• Run a file and scriber along the hinge lines of the elevator and rudder

Could a 21st century manufacturer produce a more accurate kit? Certainly.

References

Thompson Trophy Racers by Roger Huntington

The Air Racer by Charles Mendenhall (Drawings of aircraft from the late 20s to the late 70s)

Good-looking build! An unusual subject.

Thanks

I love all the Bendex and Thompson Trophy racers from the '20s and '30s. So much innovative and exploration of design, not to mention the nerves of steal the pilots had.

Your Mr. Mulligan is beautiful. You definitely turned this old kit into something special. Great job John!

I think that I've built all of the Testors racers over the years. The only survivors are the Travel Air Mystery Ship and Howard Ike. I have a Lair Solution in the stash. When I get to it, I'll put more effort into it than the Mr. Mulligan.

Nice accomplishment, John! Well done

I'm glad you like it

Really nice work on this John, and a great result.

Thanks

I wonder what a manufacturer like Dora Wings could do with the racers.

Your finished build is quite beautiful. All your time and effort has really paid off. @jsummerford

A wonderful result, John!

As always, your extra effort is clearly evident to the final result.

Congratulations!

That's a nice updating of an old kit. Some very nice additions and work.

A very nice result on this not so often seen subject, John @jsummerford

Well done.

Superb result from that ancient kit, John @jsummerford! Great scale modeling for sure!

A completely beautiful build John!

Clean and sharp.

Bravo, another old Hawk kit graces a builder's shelf. Nice result with that old kit. Some day I want to tackle their Laird Solution because Matty Laird is my great uncle.