I decided to start another thread, since I couldn't find a proper B-26 subject at the beginning, and pulled this out of the stash since the decal set I bought also included one.

I got the cockpit started (no pics yet), and originally thought I'd build with canopy closed since it would be quite a bit of work to sand down the sections to fit in an open configuration, and this kit has pre-painted canopy frames! I changed my tune when I hastily decided to open all the dive brakes (see below description), and decided to build just before pushing over to drop bombs. I'm still going to keep the forward section of the canopy closed, but think I can trim edges to make the rear sections fit open, and won't have too much re-work on canopy frames to have to do. This does mean I may do some extra work in the cockpit since at least the rear section will be open...

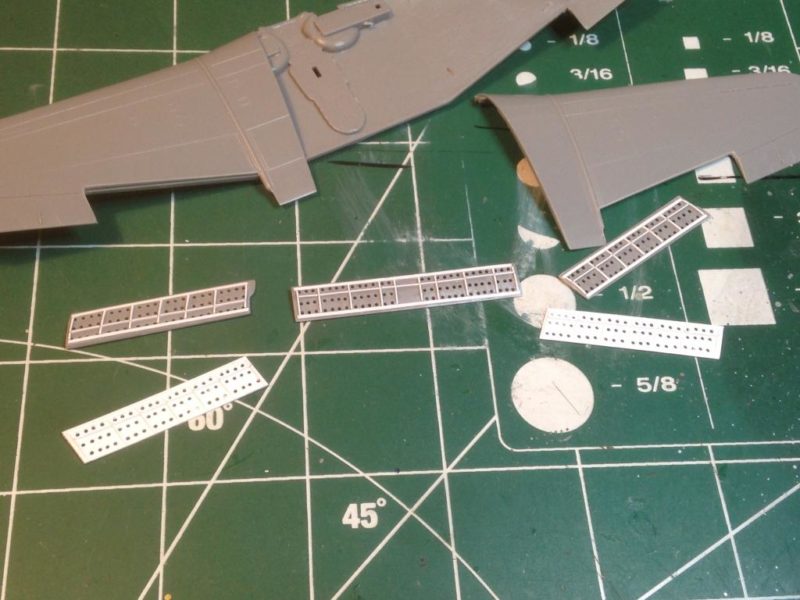

Now - about those dive brakes. Both upper and lower dive brakes (wing sections) are molded into the upper half of the wing, and originally I thought I'd just drill out the holes so it would look more realistic. I did on one of the wings, and I suddenly started thinking - what if I sand this fat baby down, cut out the upper brake and create the lower flap out of styrene?

Before I could think clearly, the files and sanding sticks came out, and I took the brake down to just about the thickness of the upper wing half, and then cut out with a knife. Before I sanded it down, I used the shape as a pattern for the lower flap, as the shape is just a tad different.

Next was to cut out the lower flaps from styrene, and finish the drilling process. I ended drilling out 378 holes (318 for the 5 units of brakes/flaps, and an extra 60 for a flap I broke while sanding - more below).

-

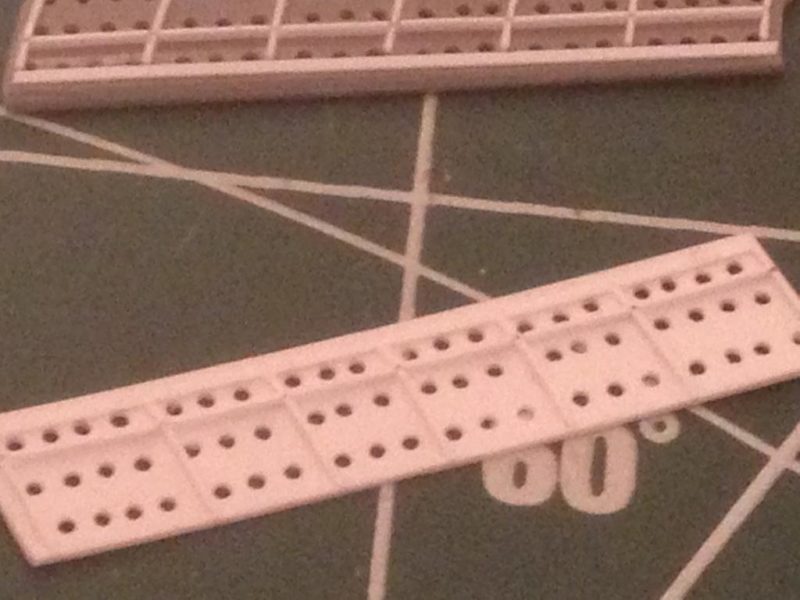

Cleaning up the drilling took some effort, especially for the softer styrene plastic. First I got the drill bit through each hole, and then backed out without reaming, because I broke one bit early in the process and only had one other of the same diameter. Once I had drilled all holes, I ran the bit back into the hole up against the end point and then reamed out the hole of excess. I did this from both sides, then used a knife to scrape across the flap/brake to get the hanging chads off. Next was to take my smallest round file and lightly ream the lip of each hole to further release remaining excess plastic. Then I sanded (lightly, after breaking one of my completely drilled flaps by sanding too vigorously!). After sanding and brushing off all loose stuff, I inserted the brush tip of Tamiya glue into each hole to further clean up the small remaining excess.

-

It was very hard to get the holes perfectly aligned, but it looks more realistic than little indentions in the flaps/brakes! The sections are also thicker than scale, but I decided to keep it this way, as the thinner styrene I experimented with didn't drill well and didn't hold it's shape very nicely.

Now comes the fun part! Before all this, I really hadn't done research on just what the undersides of the flaps/ brakes and the actuators looked like. Yikes! (a few pics of my research..)

So, out came the styrene strip in .01 x .02 dimension, and away we go. I laid down the runners at the front and trailing edge of each brake (the wing flaps didn't really have the training edge runner). Then cut 38 ribs and glued edgewise, and then sanded to shape. Next I had to create the center runner for each piece, but did so by cutting individual "spacers" to run between each rib (33 spacers total, also glued edgewise).

Yet to come: I need to even up the upper and lower wing sections where the flaps/brakes mount, blank it off and drill it out, and add the actuators. I also need to create the detail under the center section flap/brake up against the fuselage and inner wings.