CASA 2.111 conversions. Movie stars of “Battle of Britain” 1/48 scale Monogram

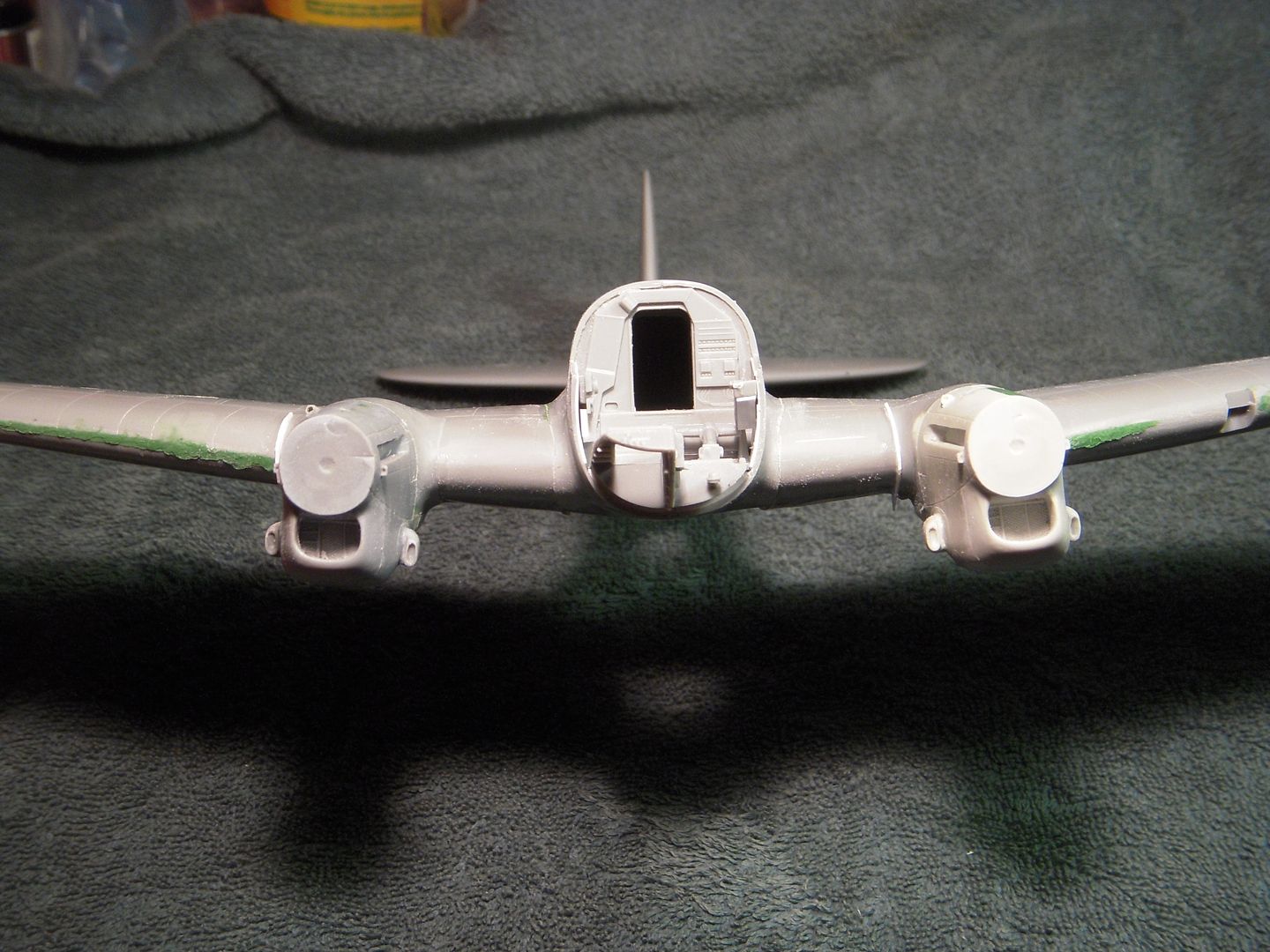

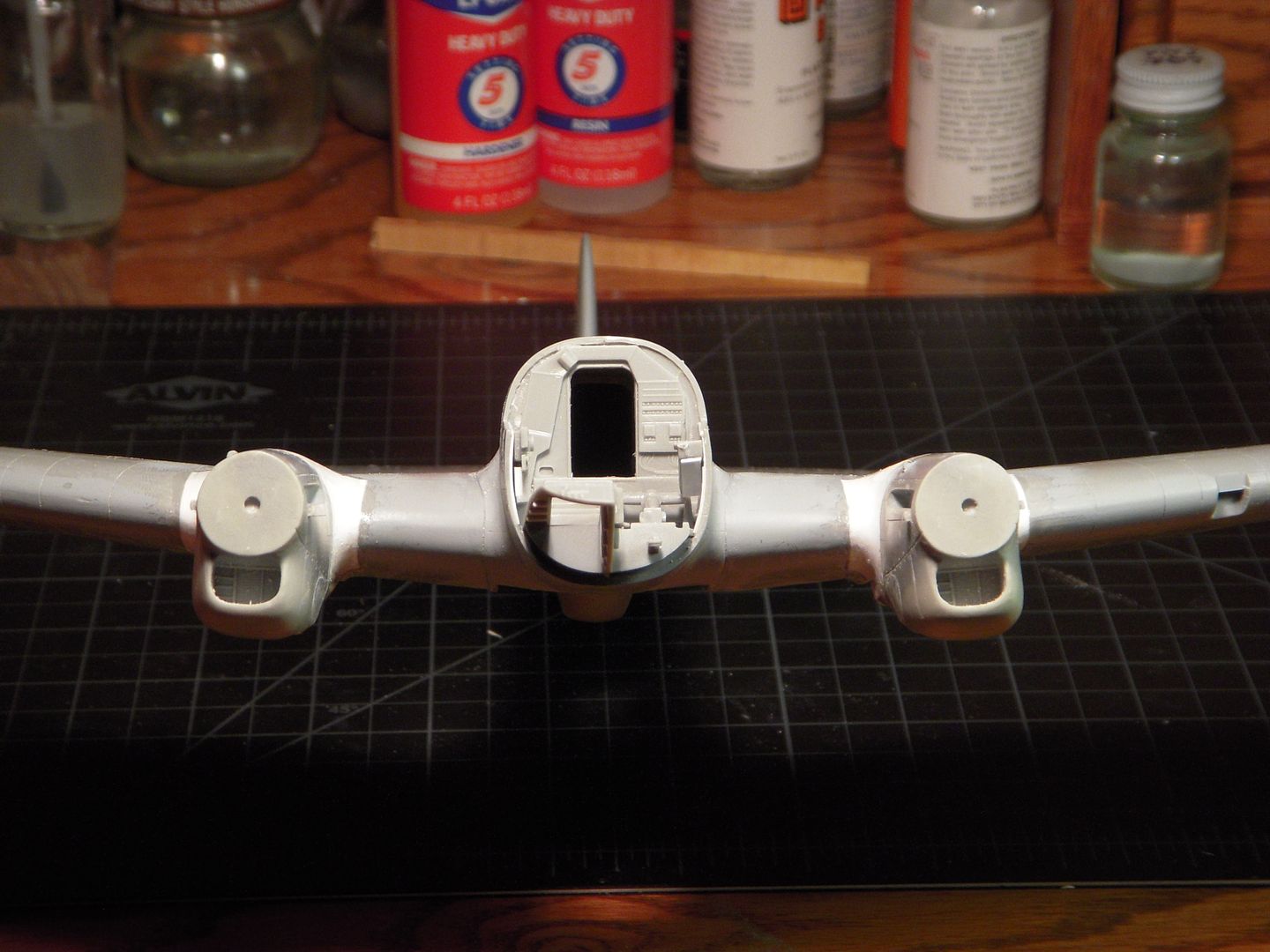

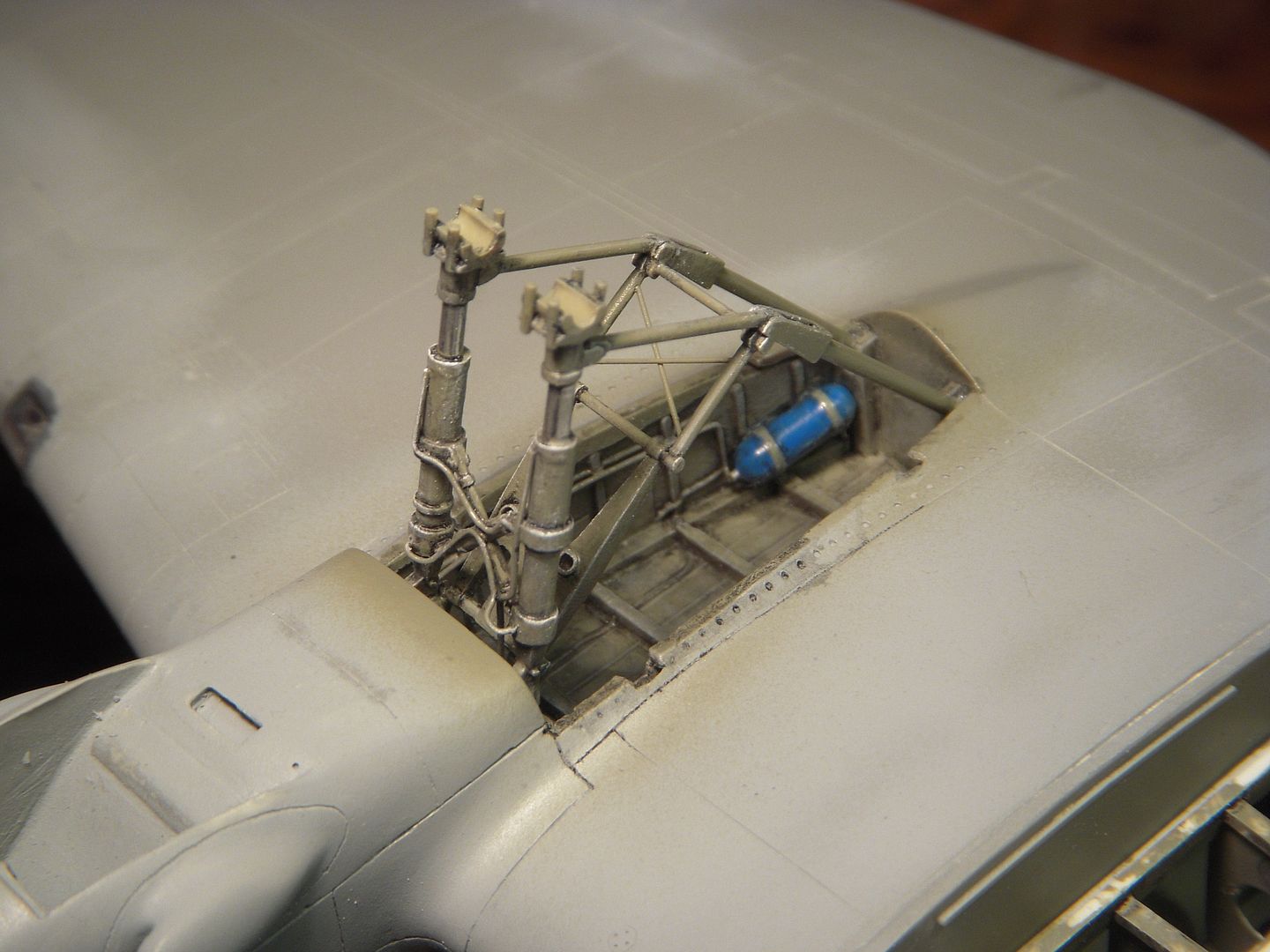

. I have been building a series of models depicting movie stars, aircraft that were used to film one of my favorite movies "The Battle of Britain". The series started with a conversation with good friend about models we would like to build. Both of us have many fond memories of BoB and my project instigator friend mentioned he had two Academy Hispano 1112s in his stash. I was welcome to one if I'd build the other for him. How could I resist, after all how hard could it be? The Hispanos are finished as well as a pair of Spitfire and a brace of Hurricanes. Rounding out the "Battle of Britain" movie stars series build are a pair of CASA 2.111s. Basically a Spanish built Heinkel He-111H-16s re-engined with Merlins, 32 CASA 2.111s were made available to film the movie in 1968. I began with the Monogram He-111H-22 in 1/48 scale, this version had a turret in the dorsal position rather than the oblong canopy found on the earlier versions. As the dorsal and ventral positions would need to be replace by the late enclosed positions anyway the use of the later version was of little concern. I obtained a set of Belcher Bits Merlin engines designed for the Tamiya Lancaster and the work began.

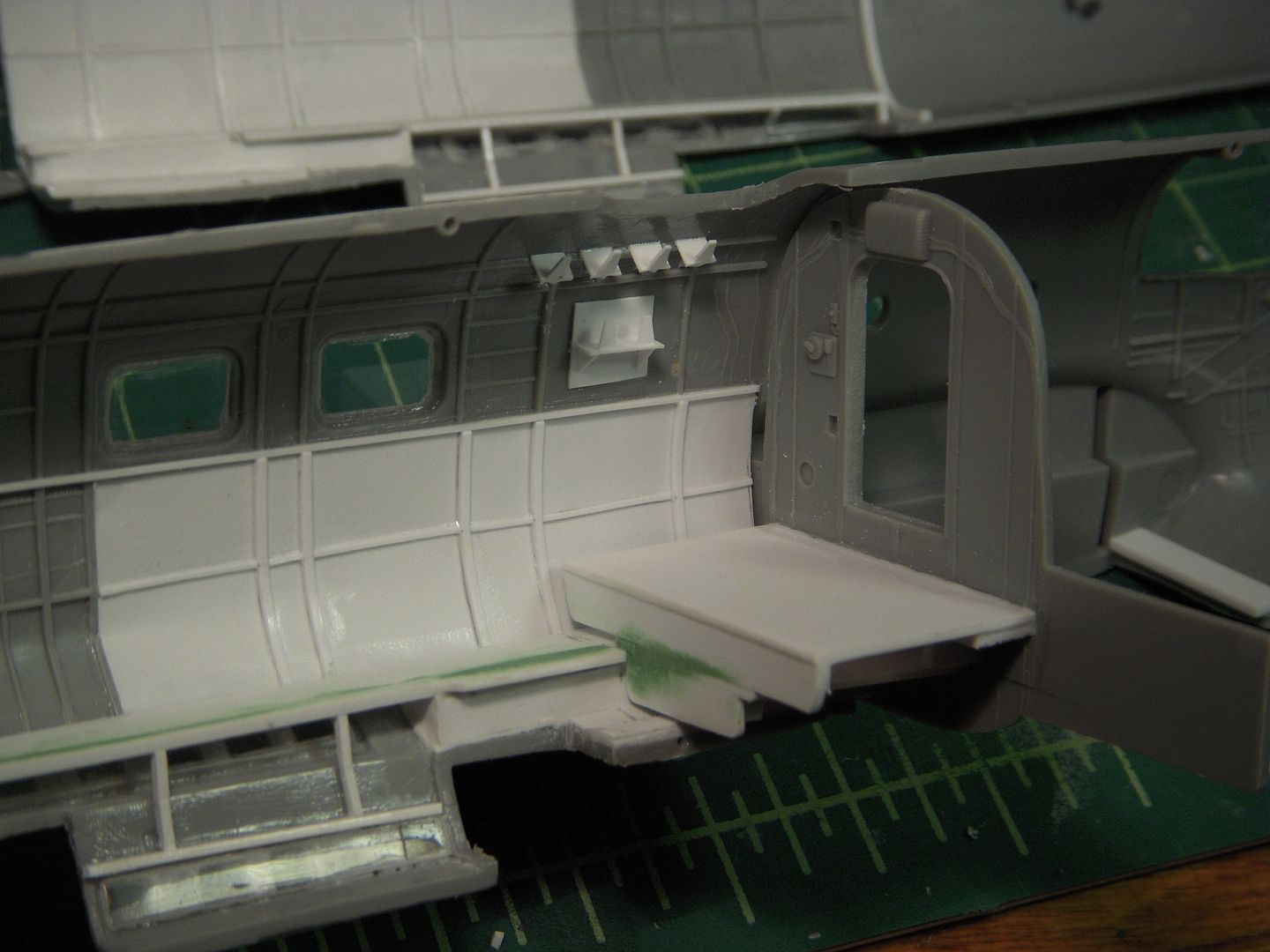

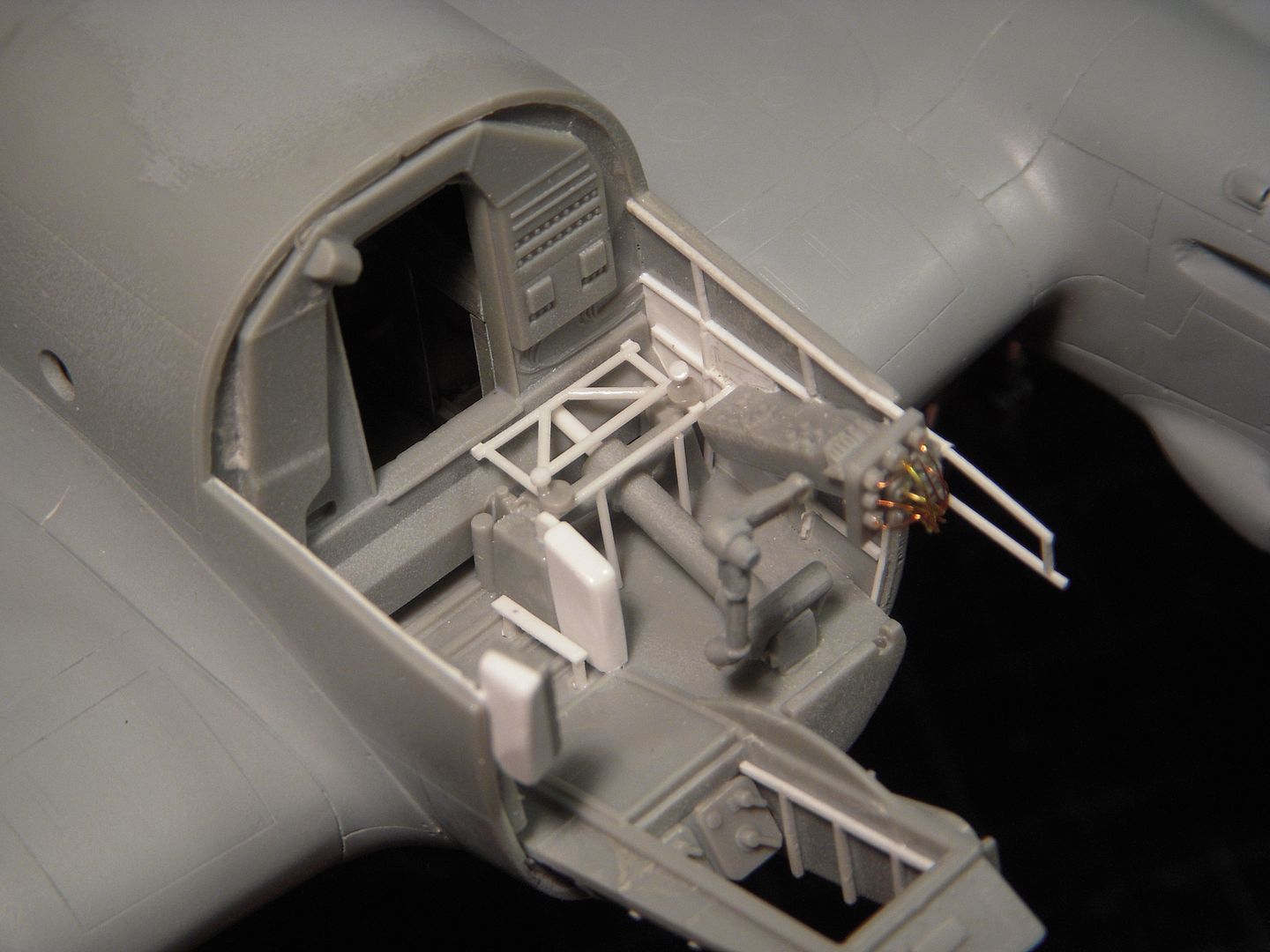

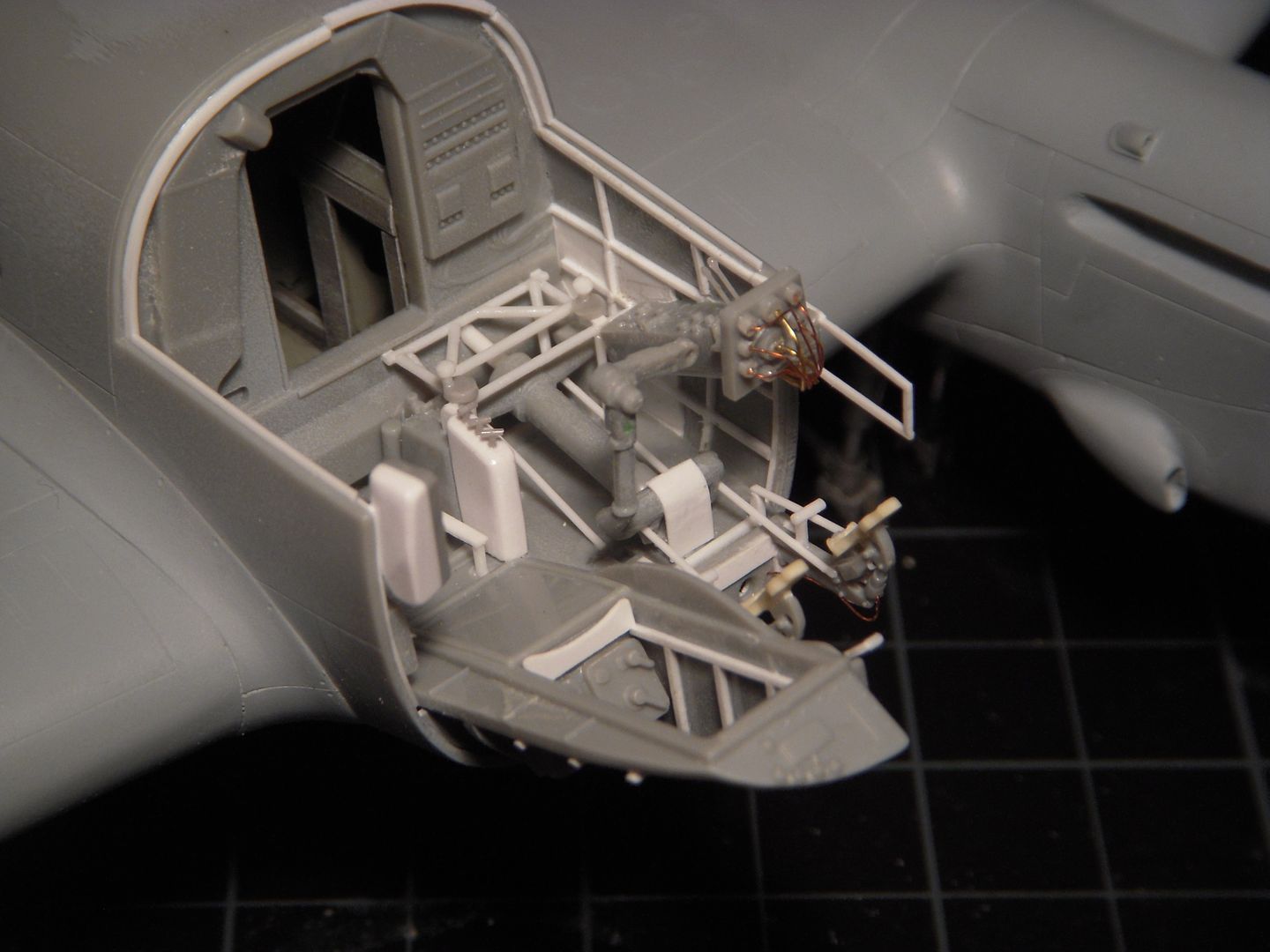

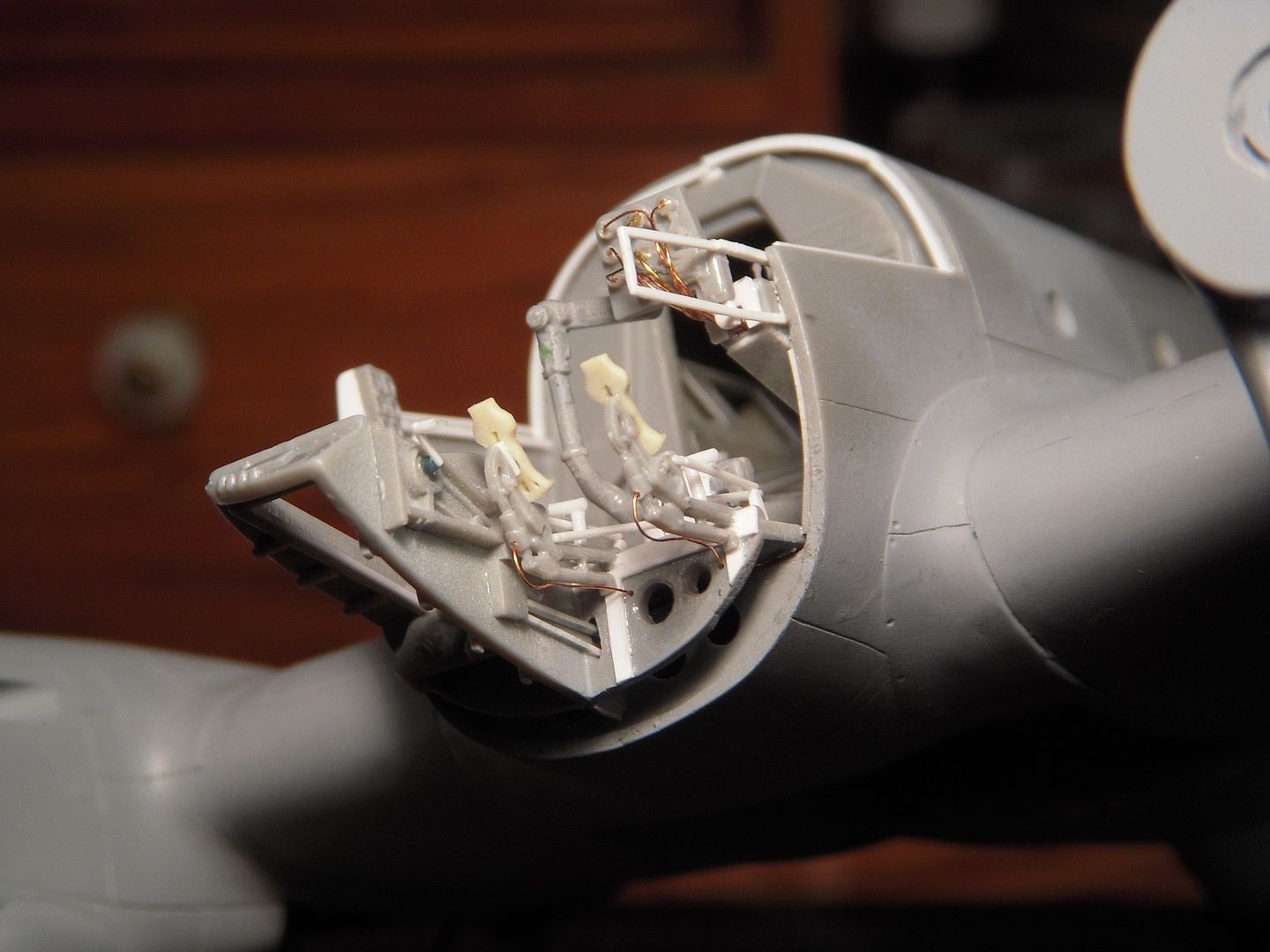

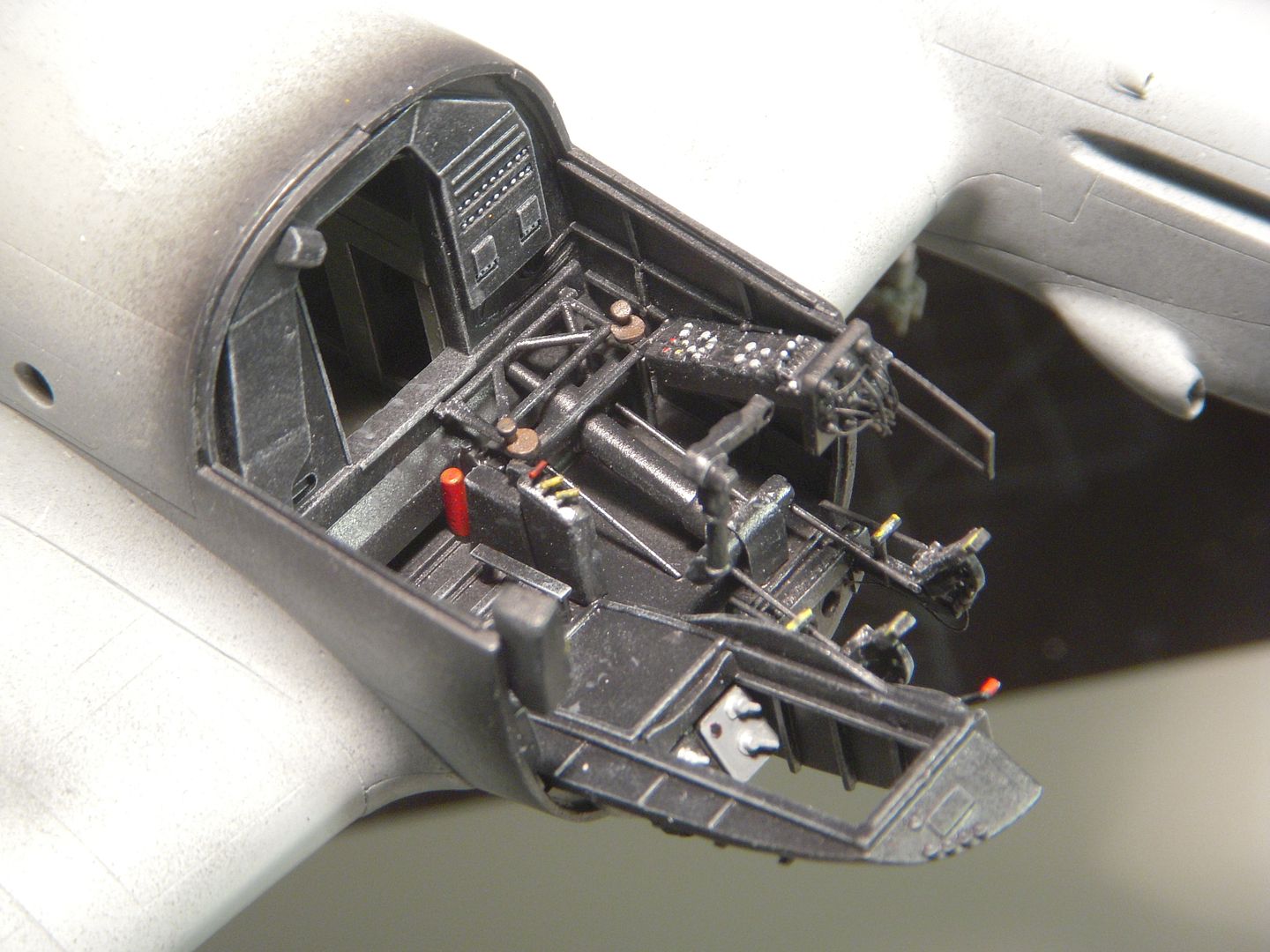

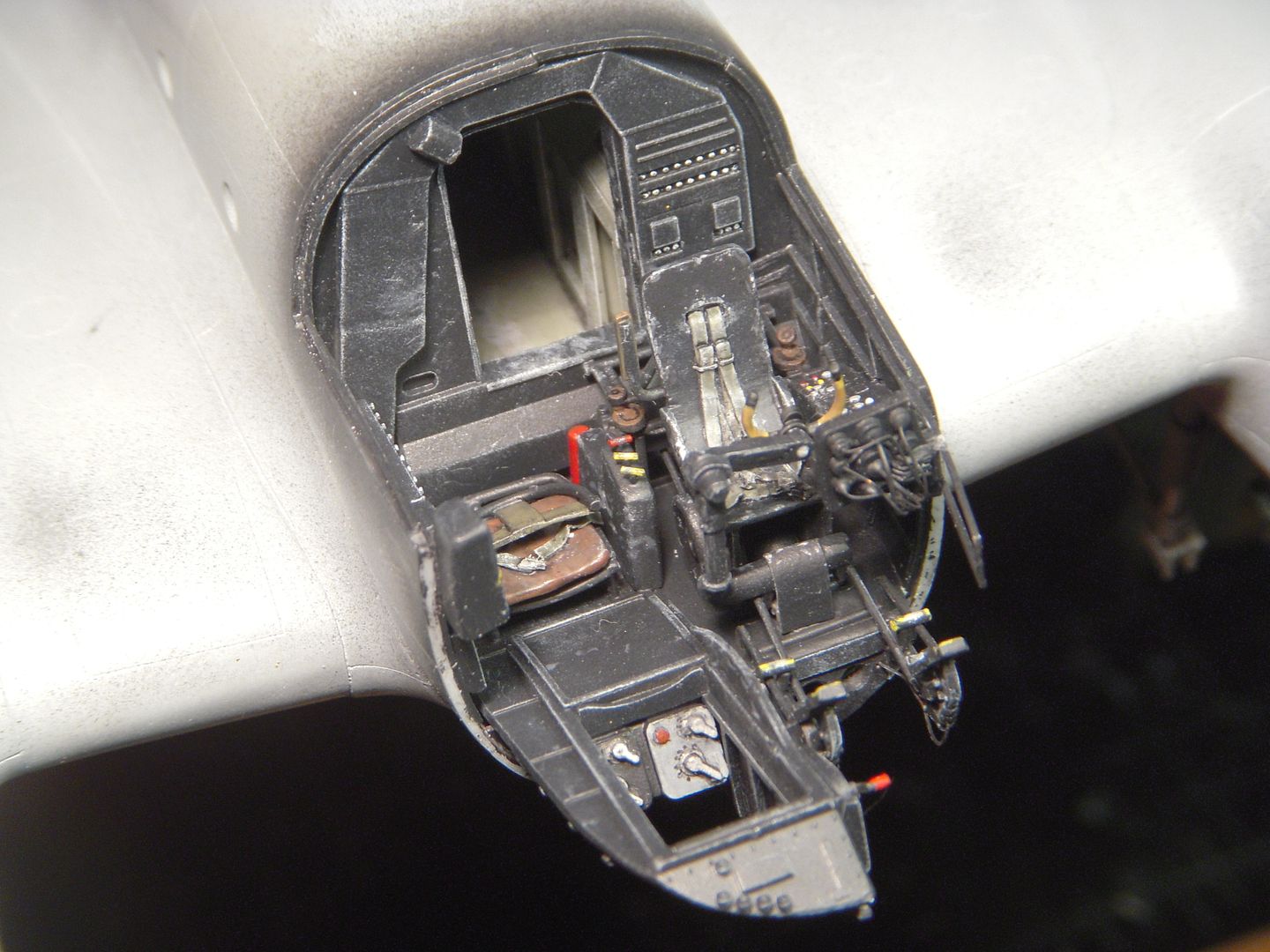

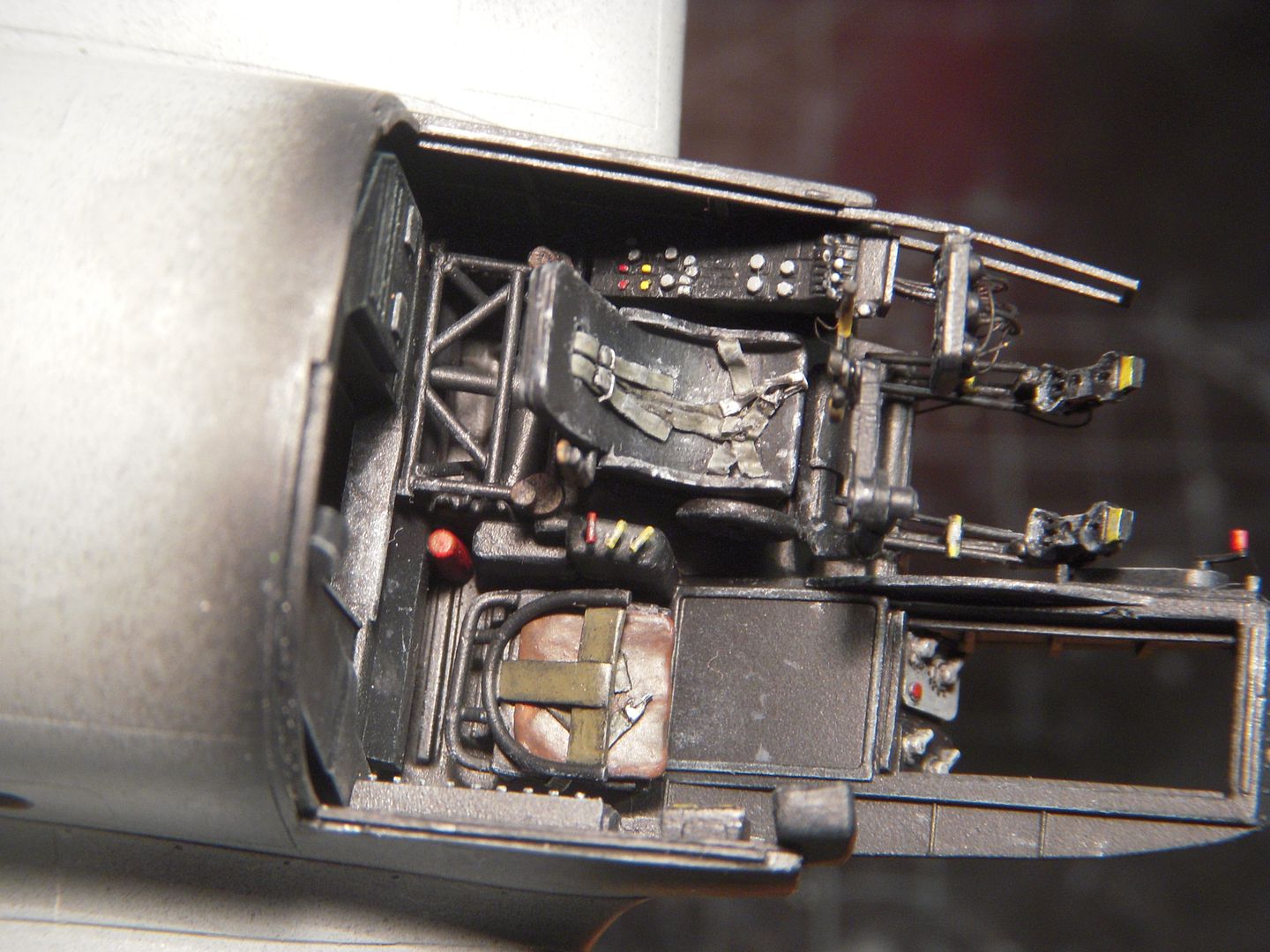

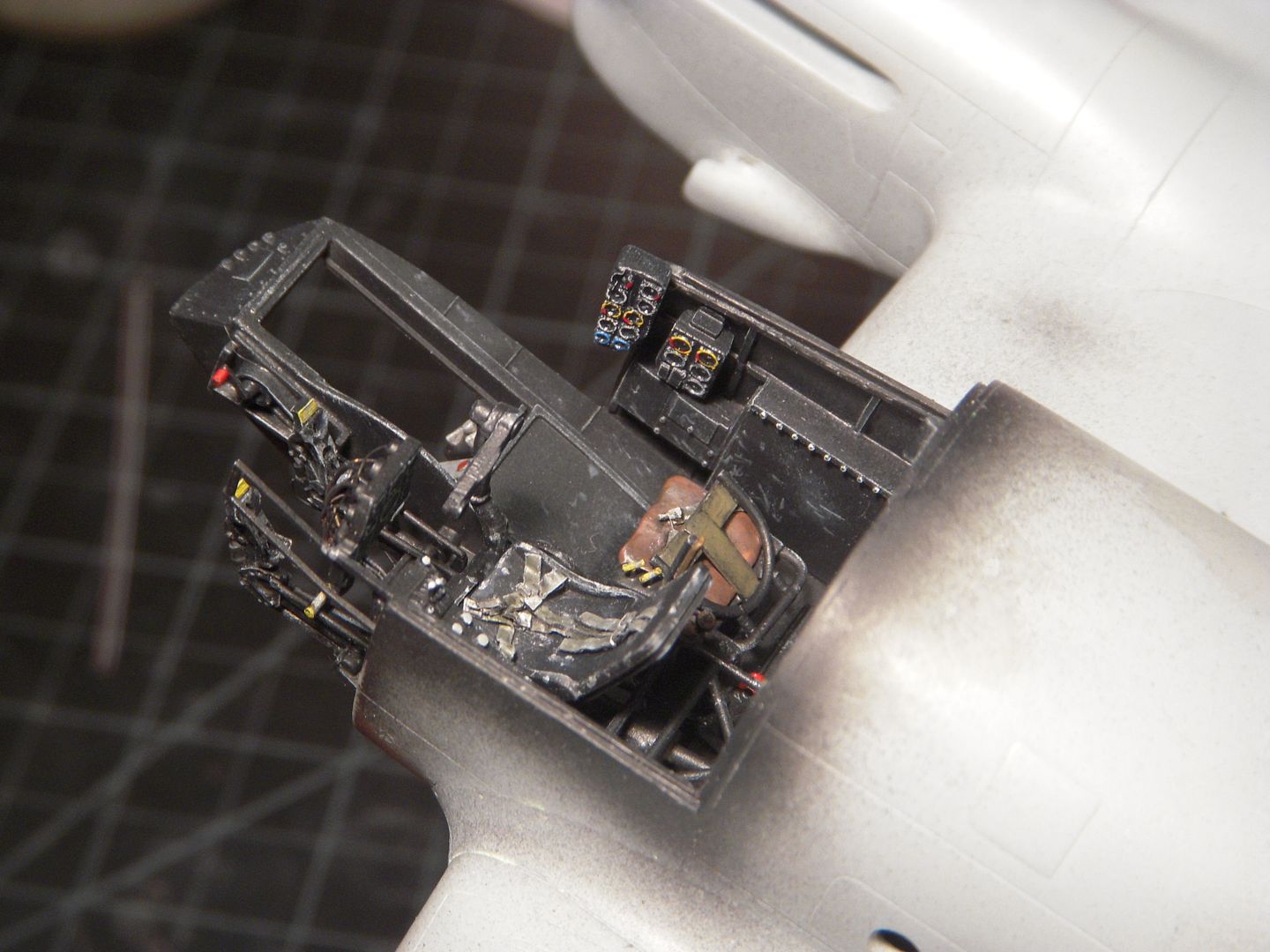

Basic fuselage detail was built up using movie (lots of pause and step on my DVD copy!) as my primary reference as an actual CASA fuselage section was used to film the interior scenes so therefore should be fairly accurate as to what the CASA's really looked like inside.

Painted...

...wash and highlighted much exaggerated as it will be fairly dark in here once the fuselage is closed up.

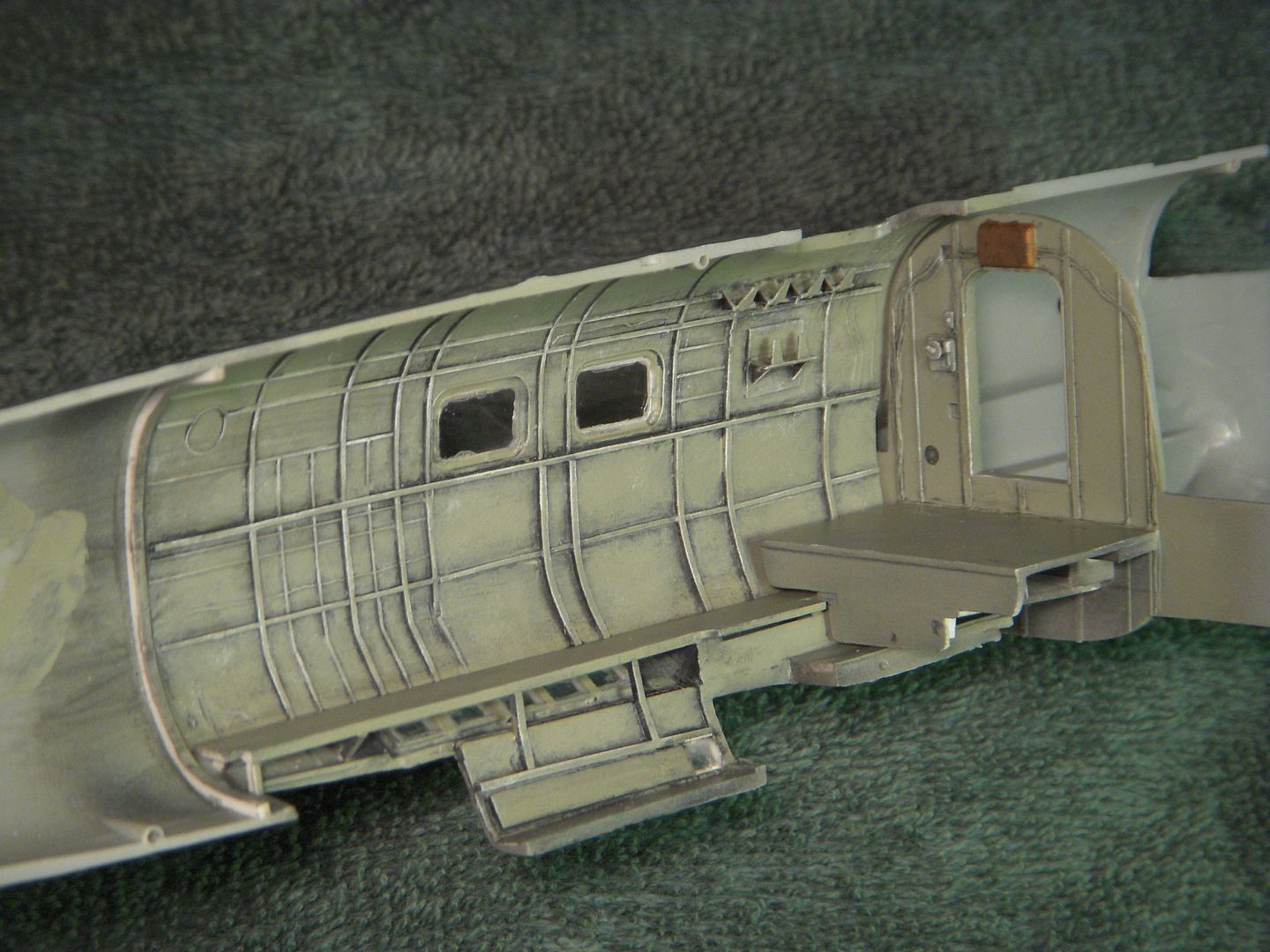

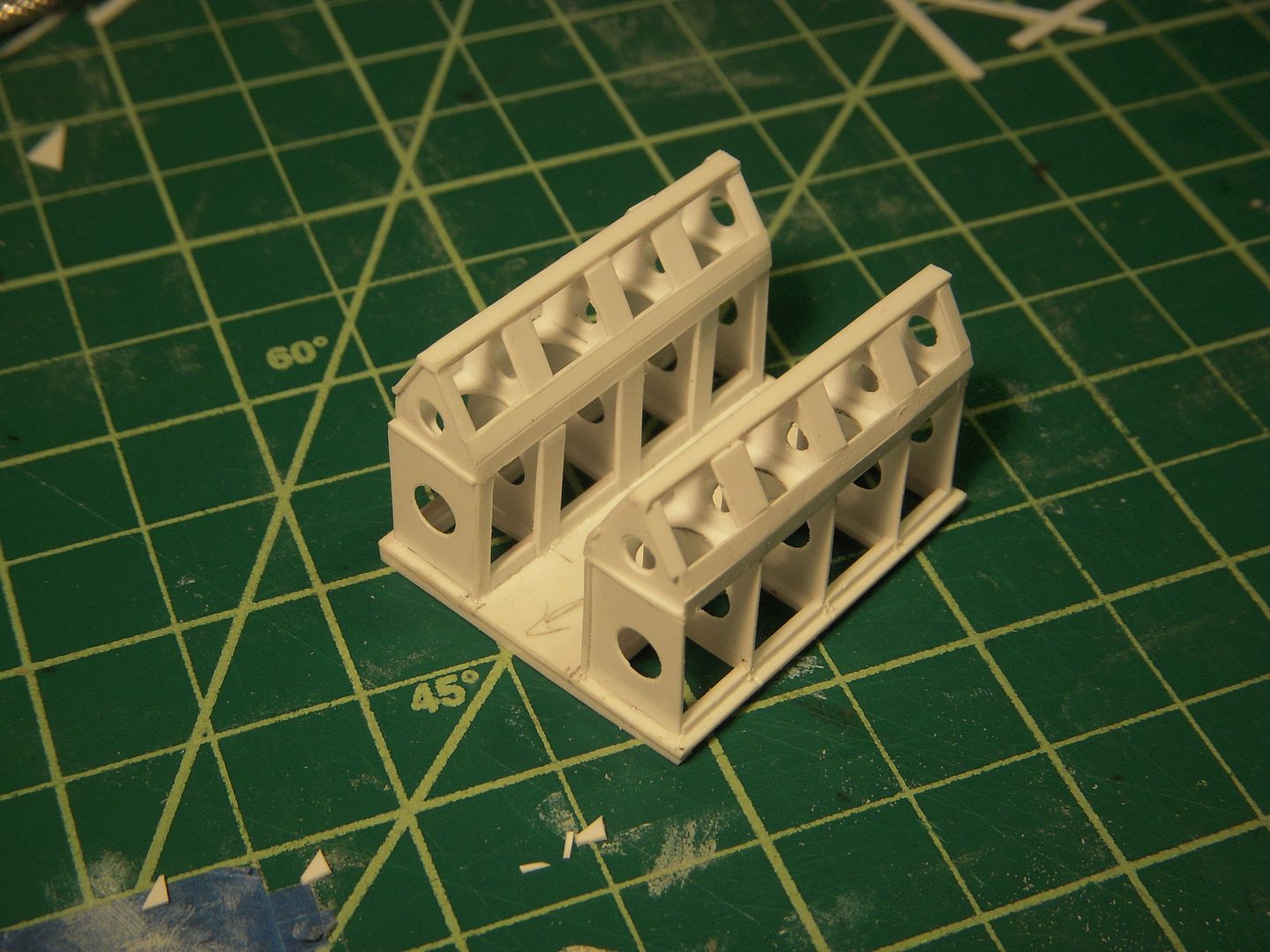

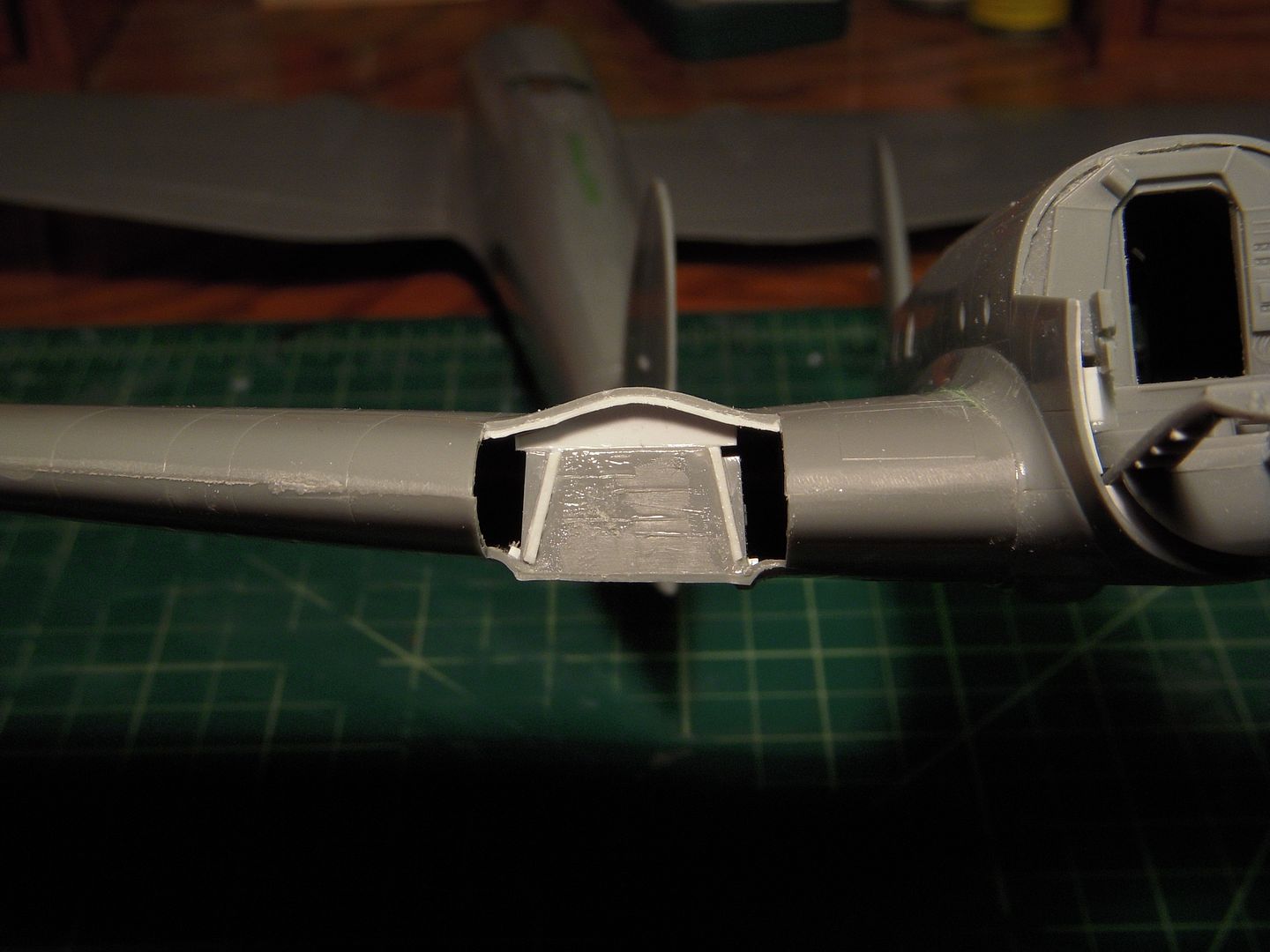

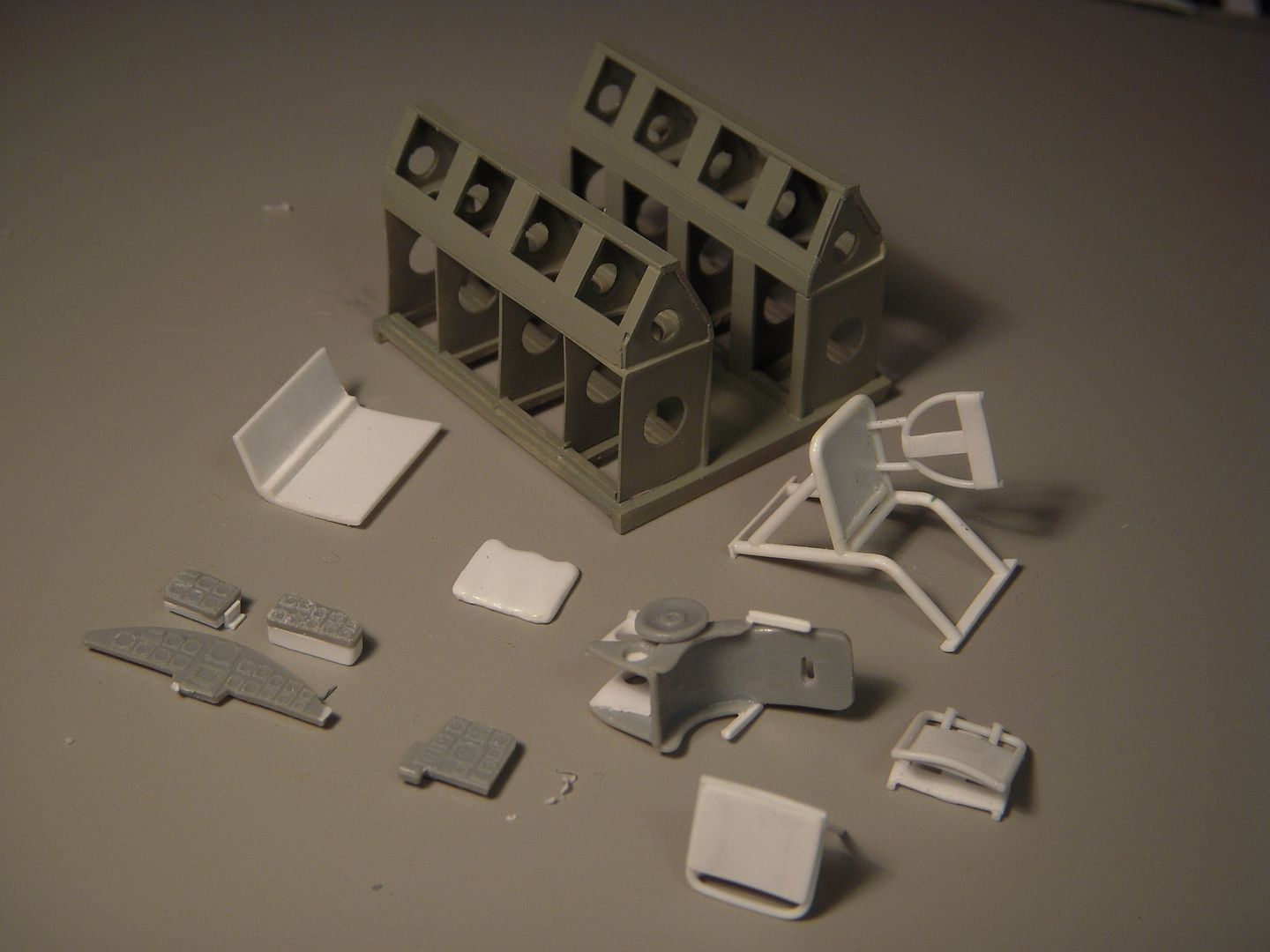

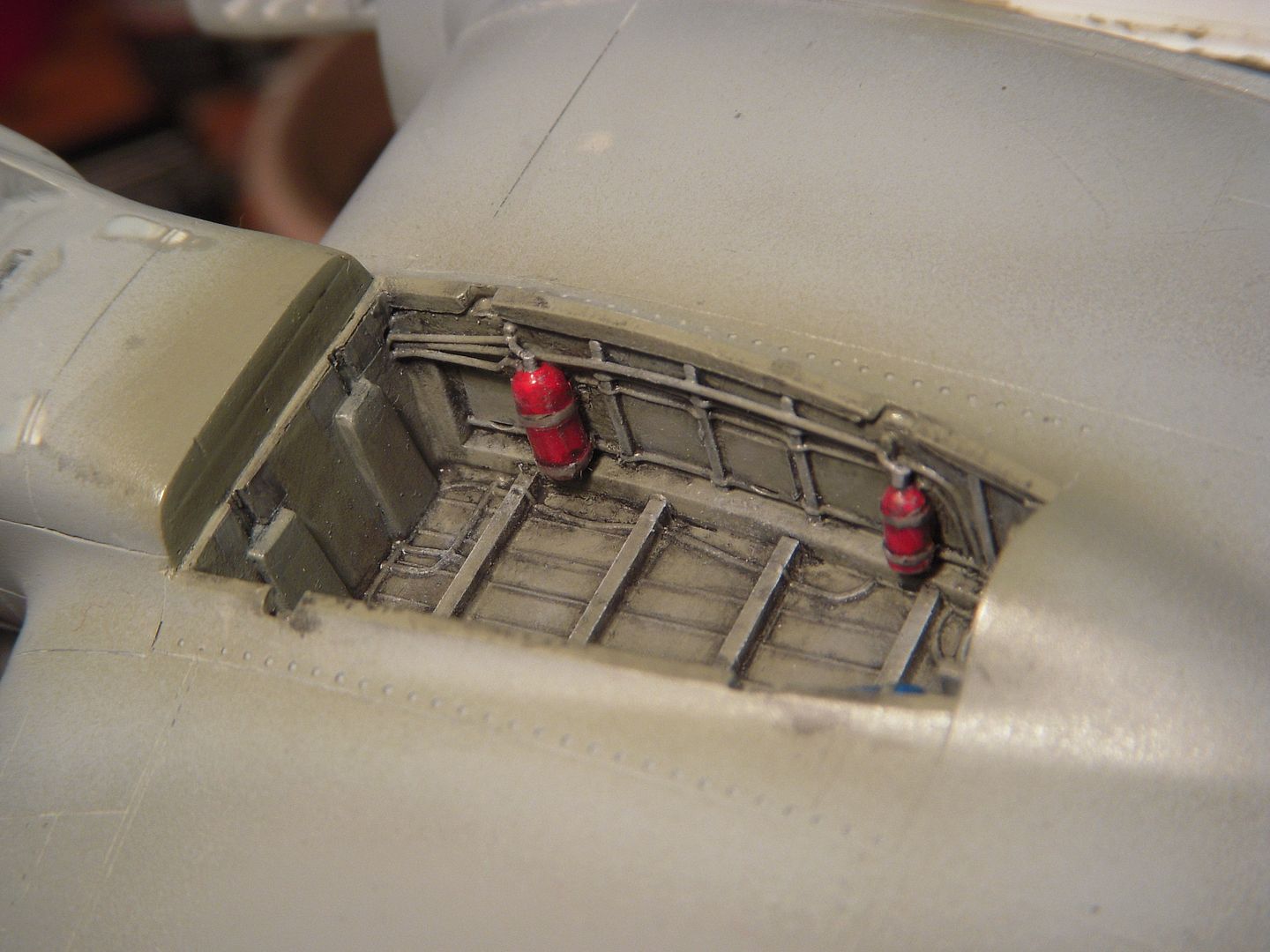

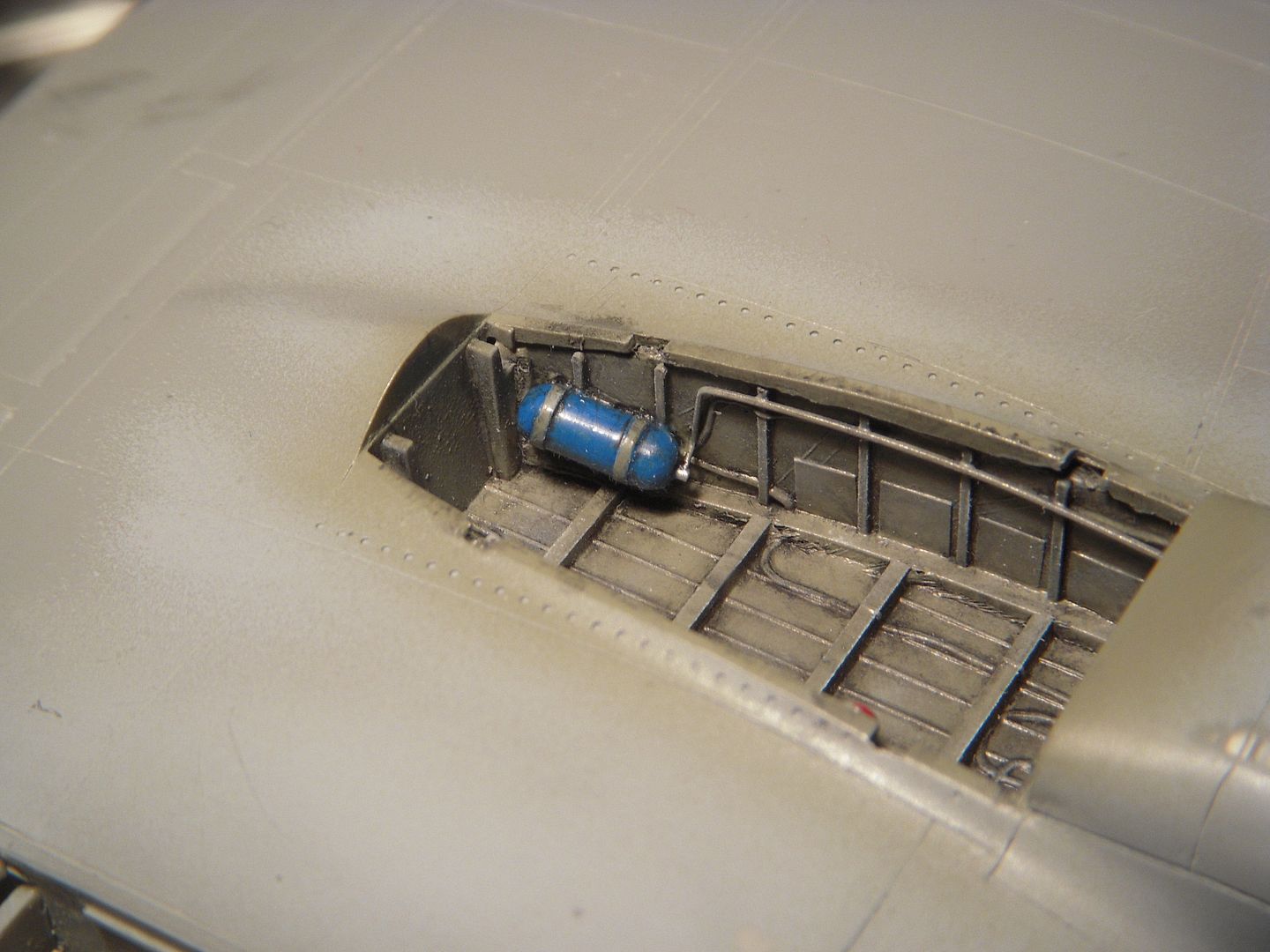

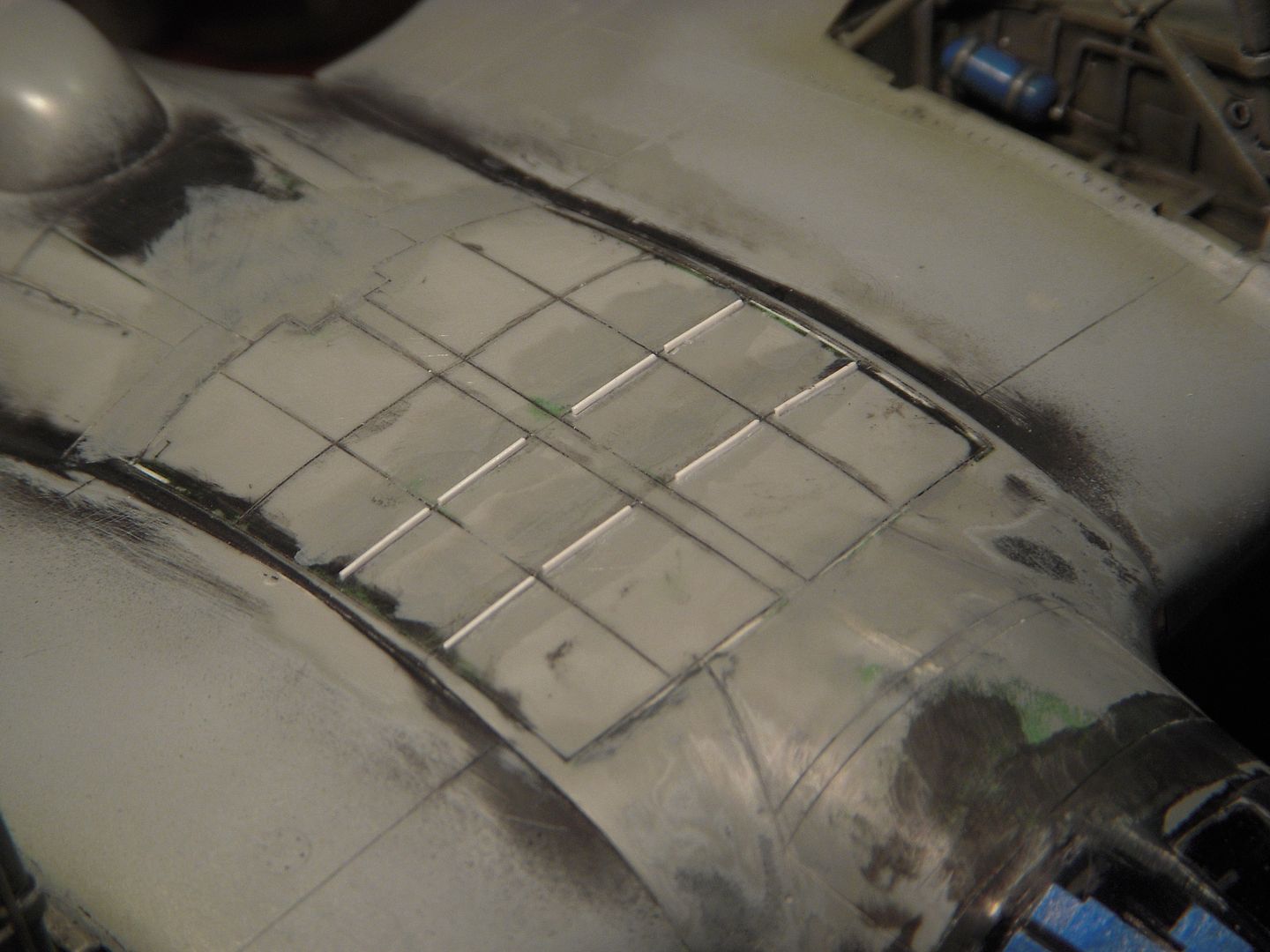

One of the images from the movie that stick out in my mind was the distinctive vertical bomb racks that could be seen in the interior scenes. This of course meant I had open up the bulkheads in the kit and build up a somewhat simplified set of racks from styrene

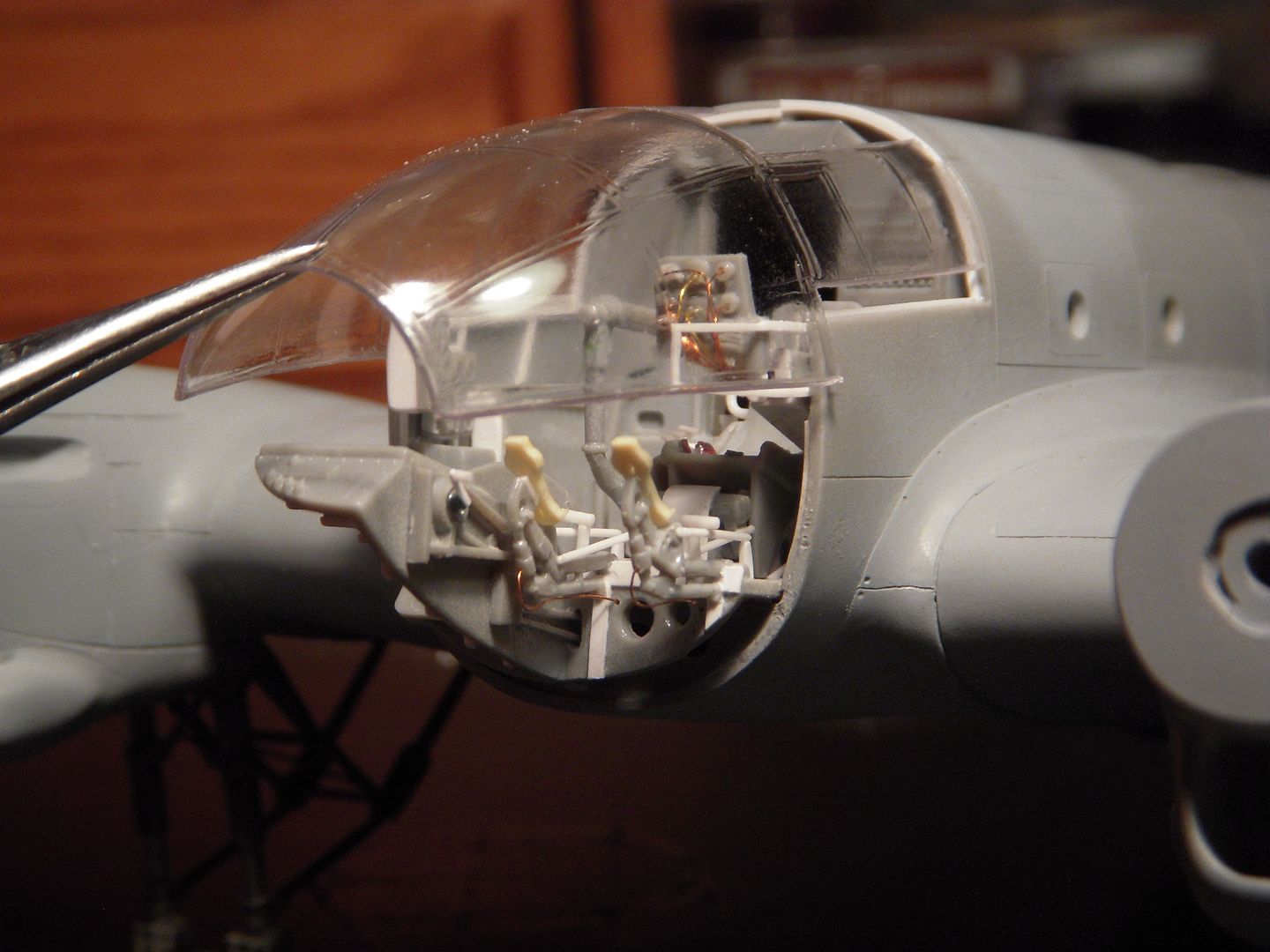

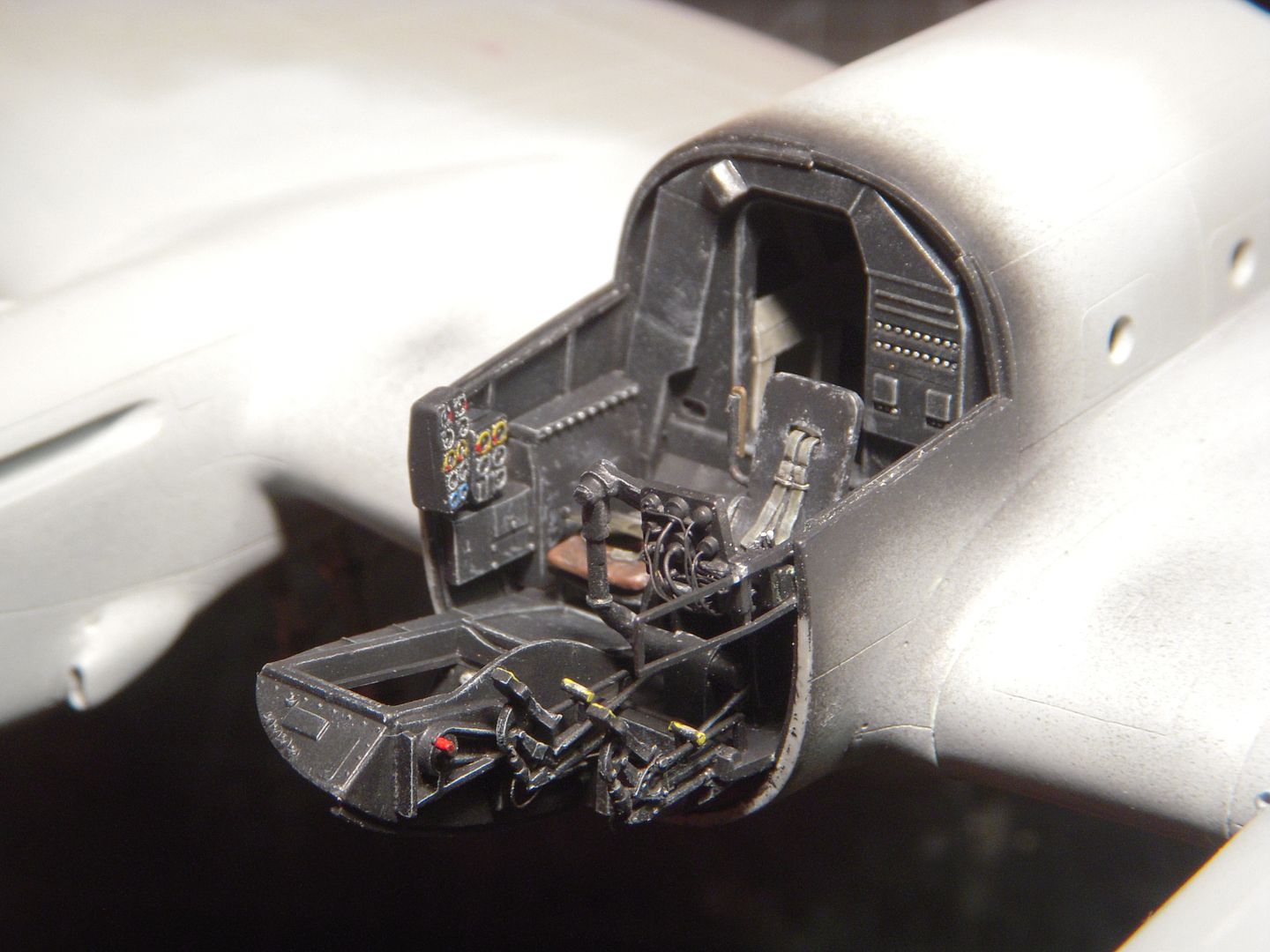

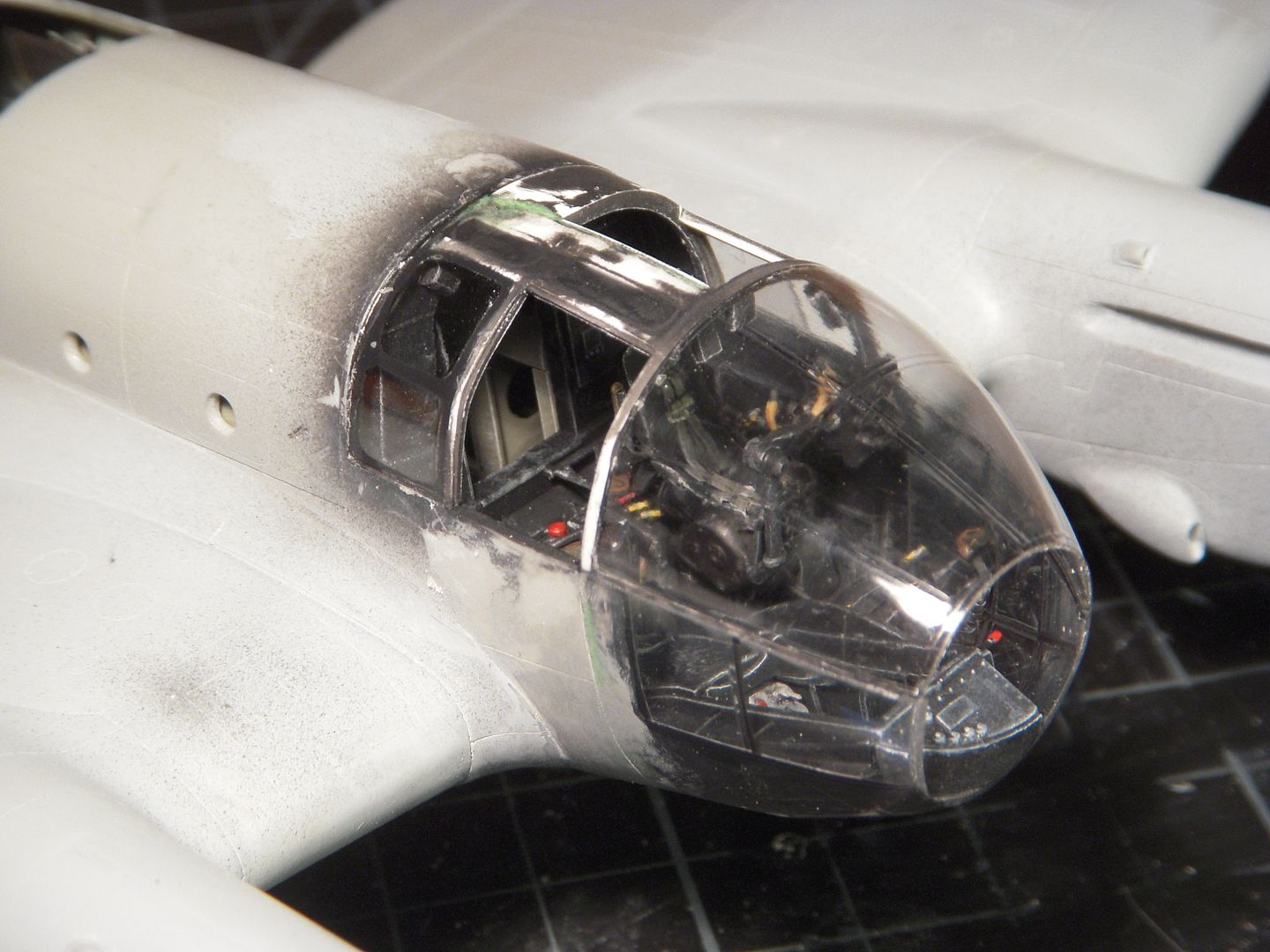

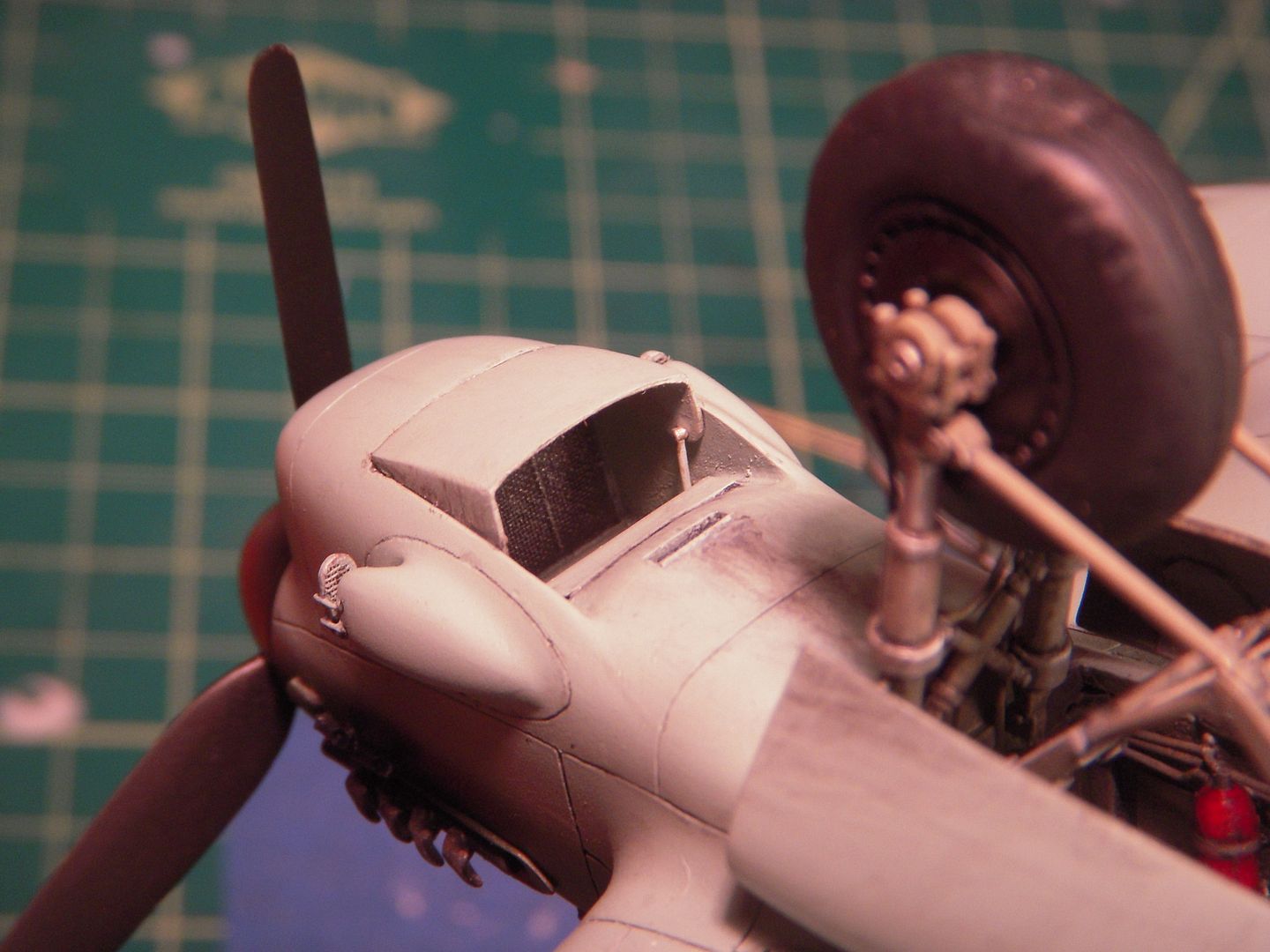

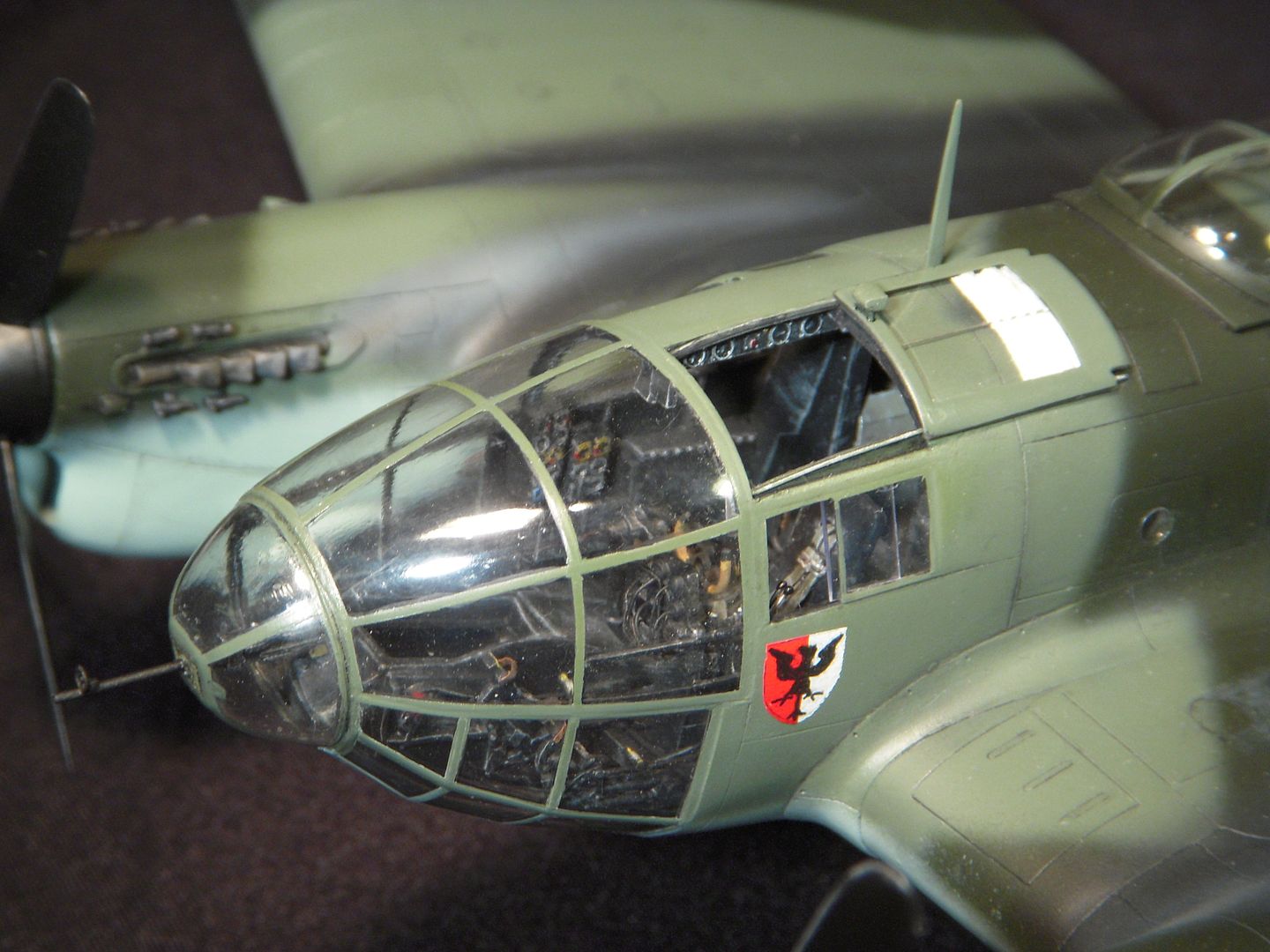

A little bit of extra detail has been added to the very visible cockpits.

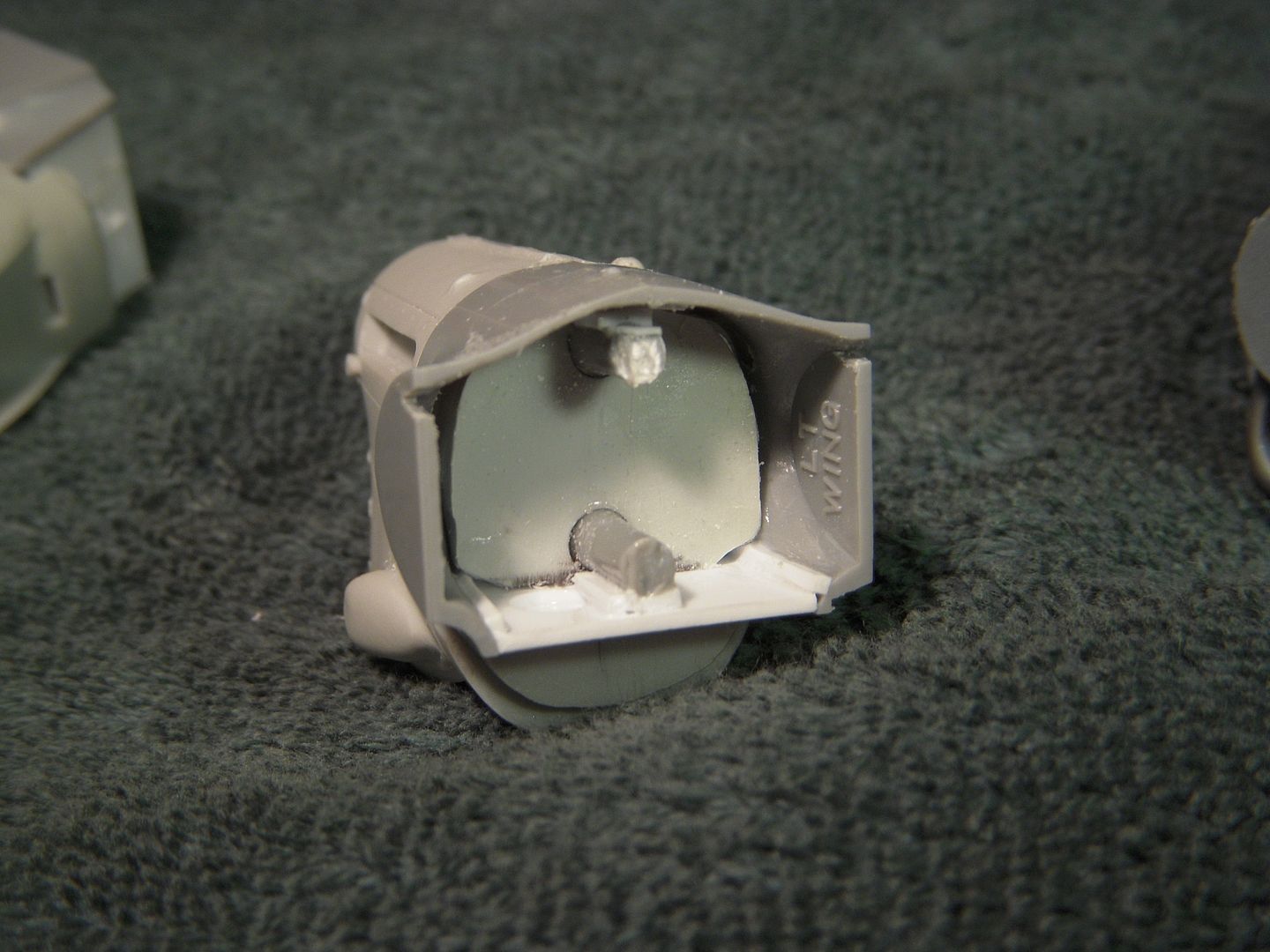

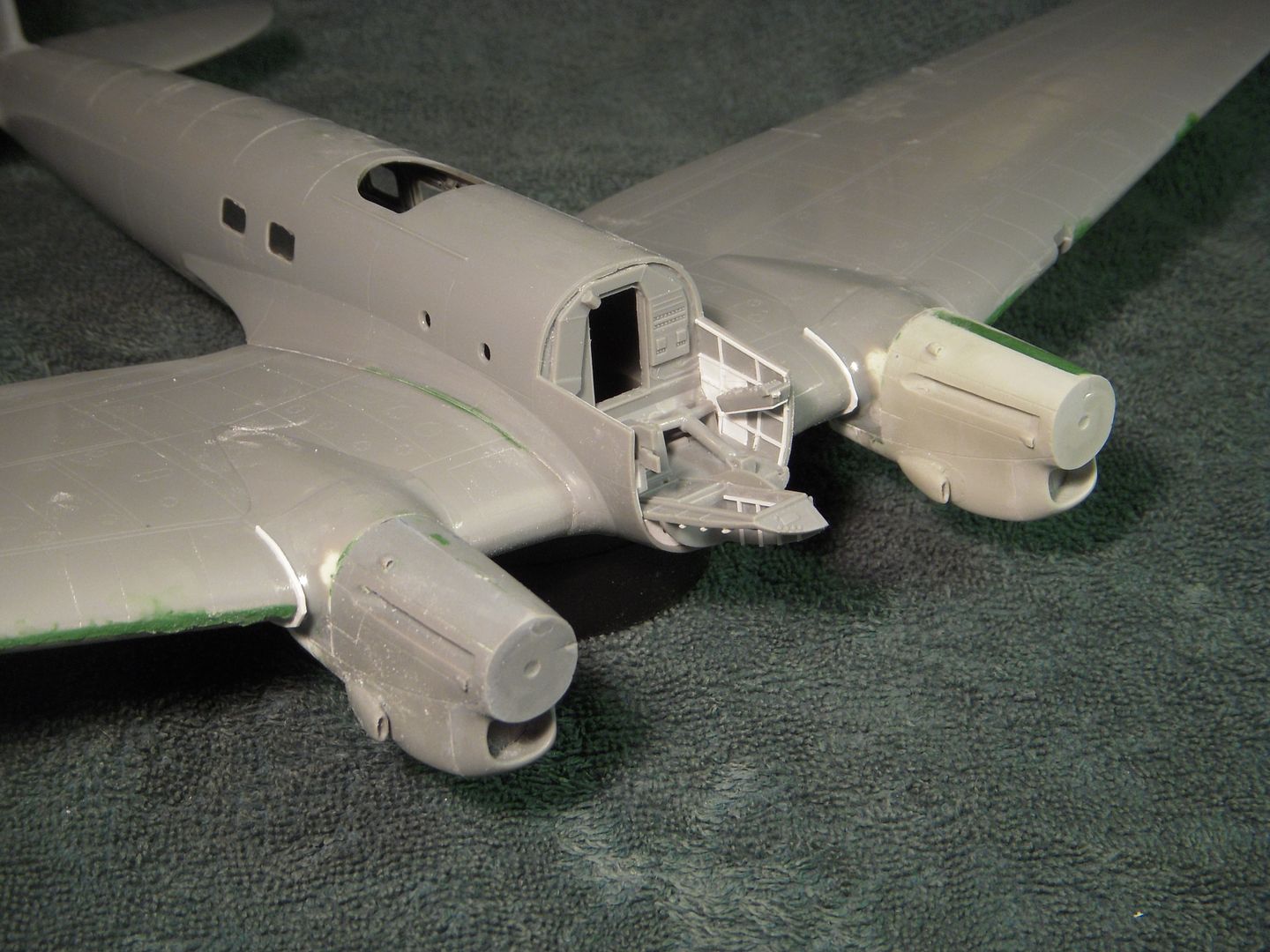

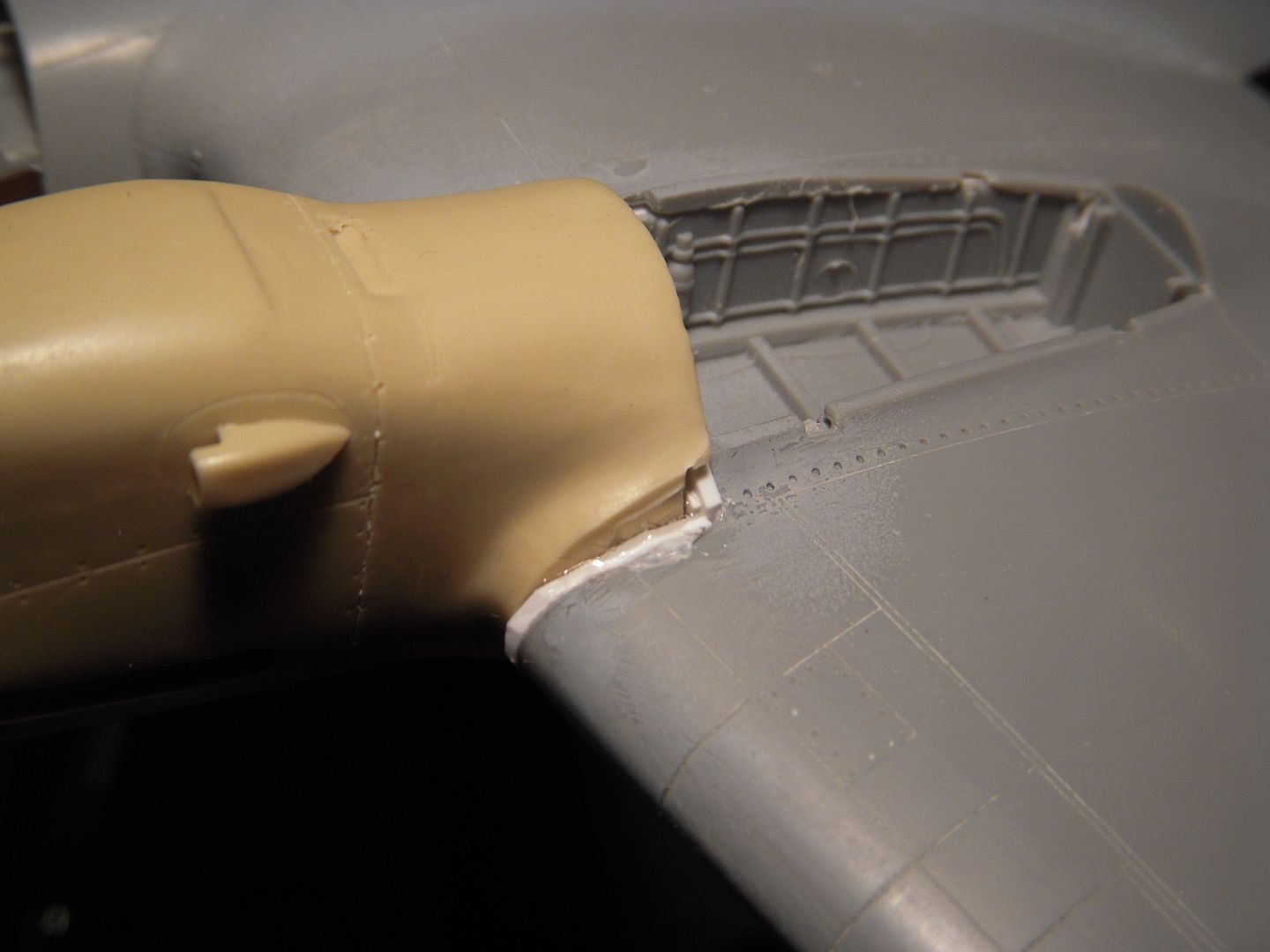

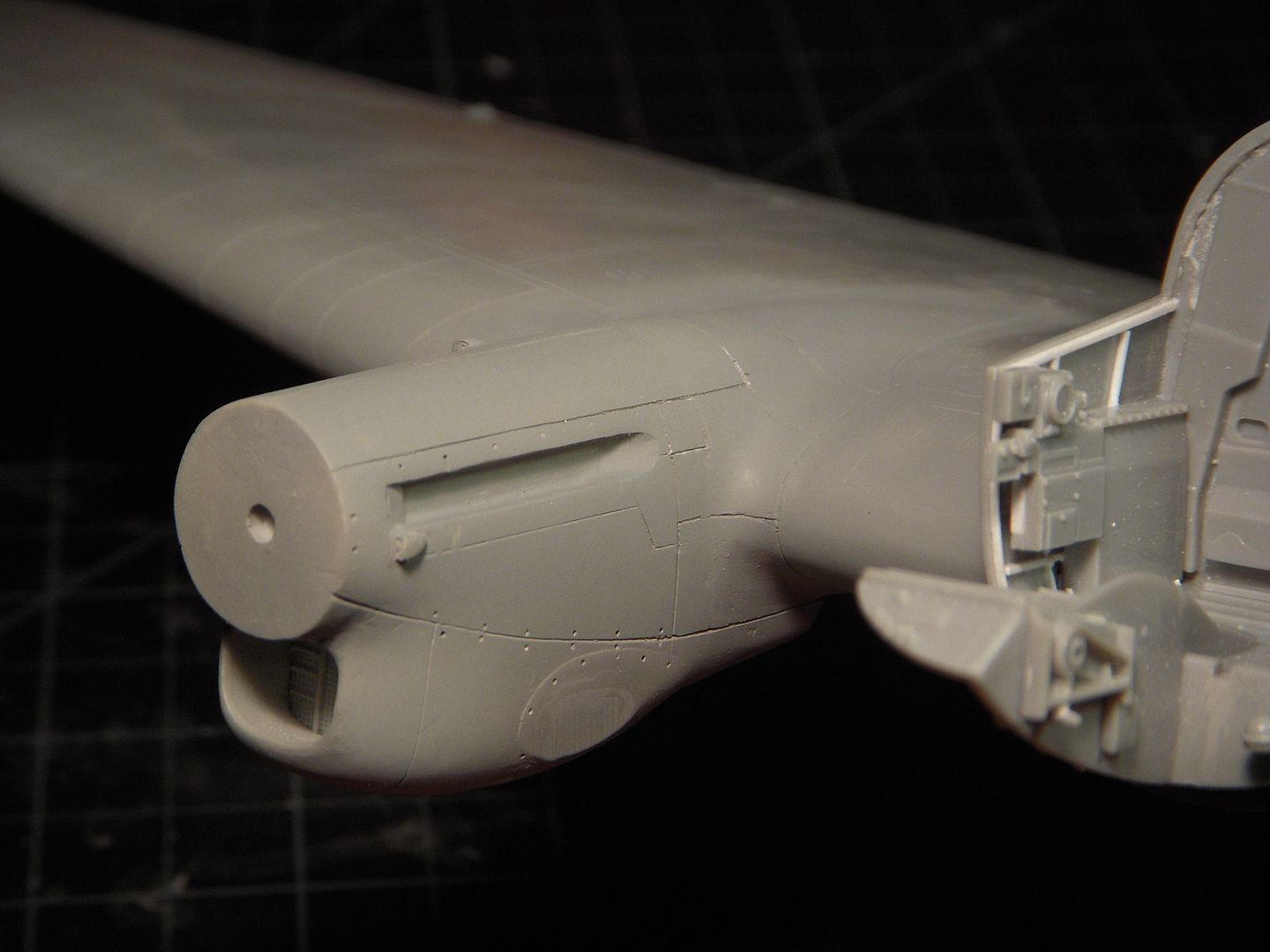

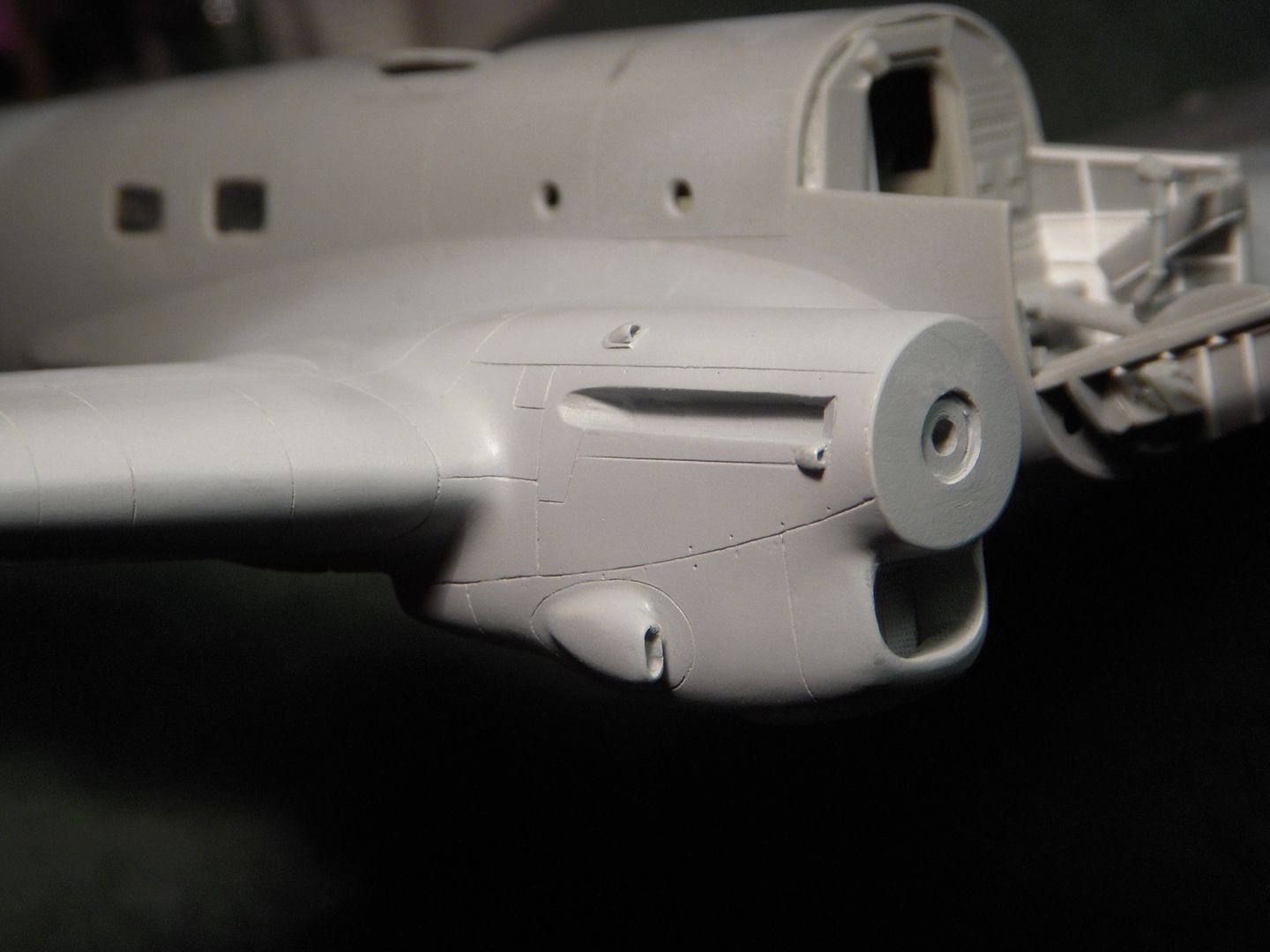

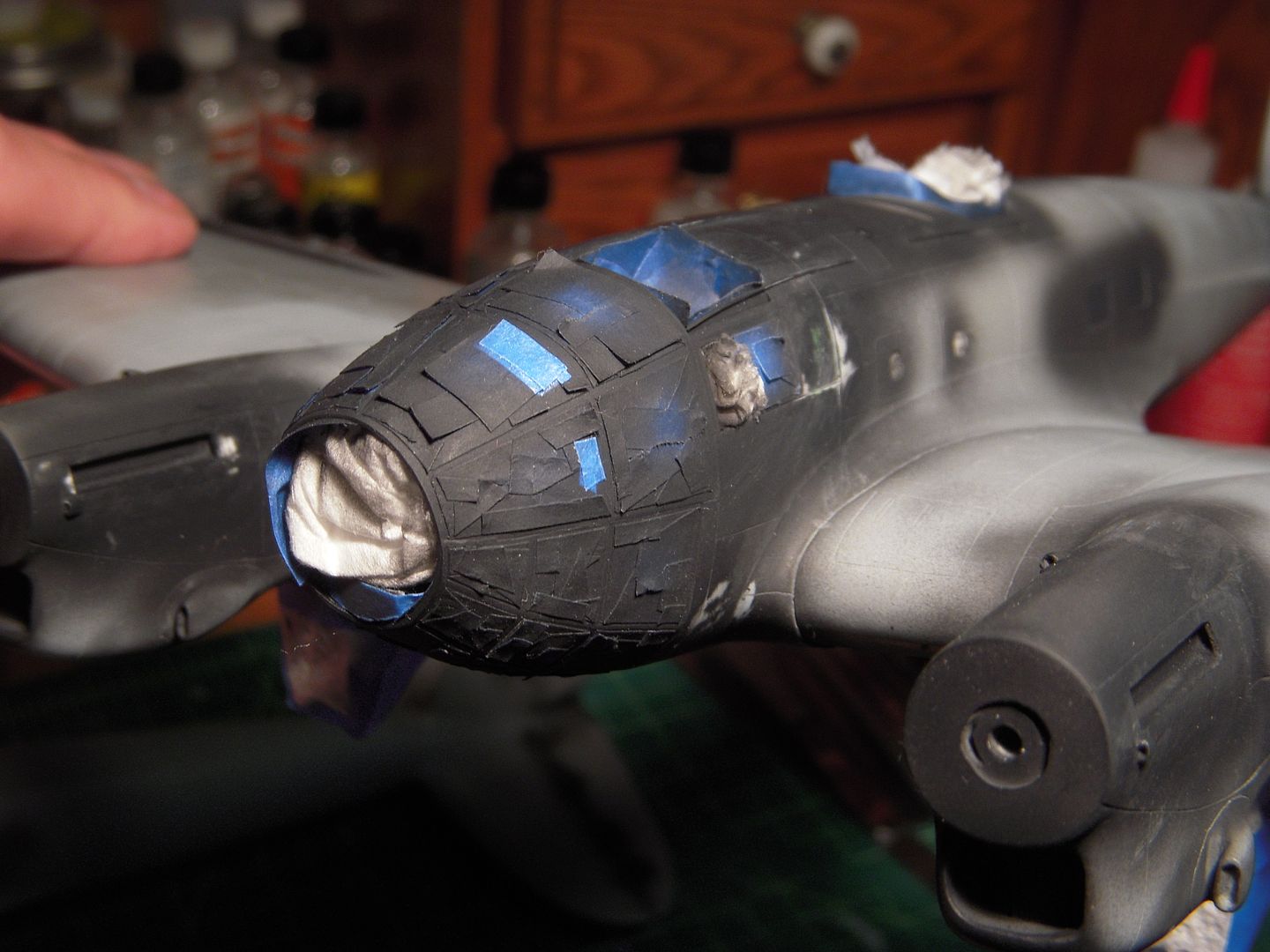

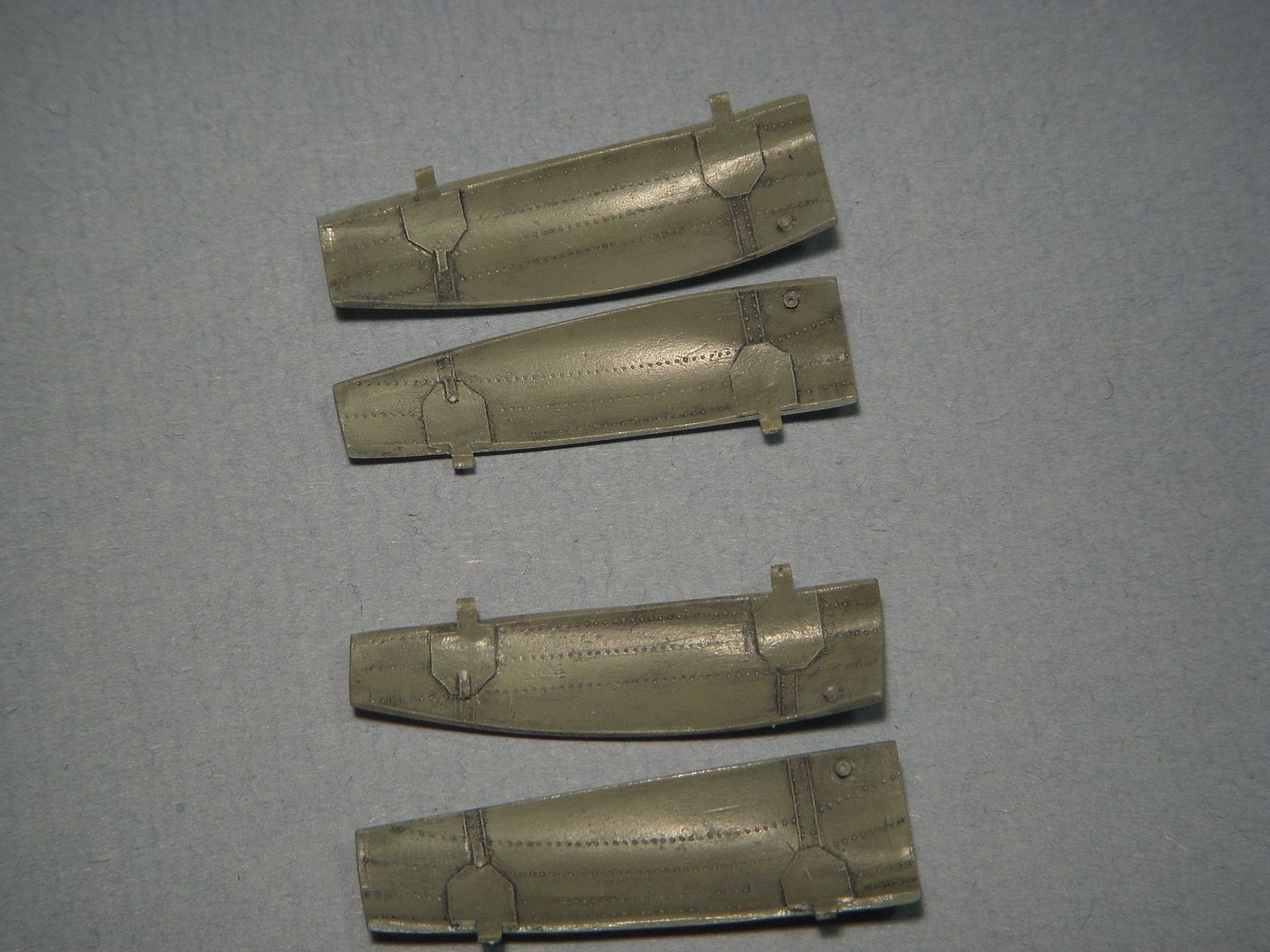

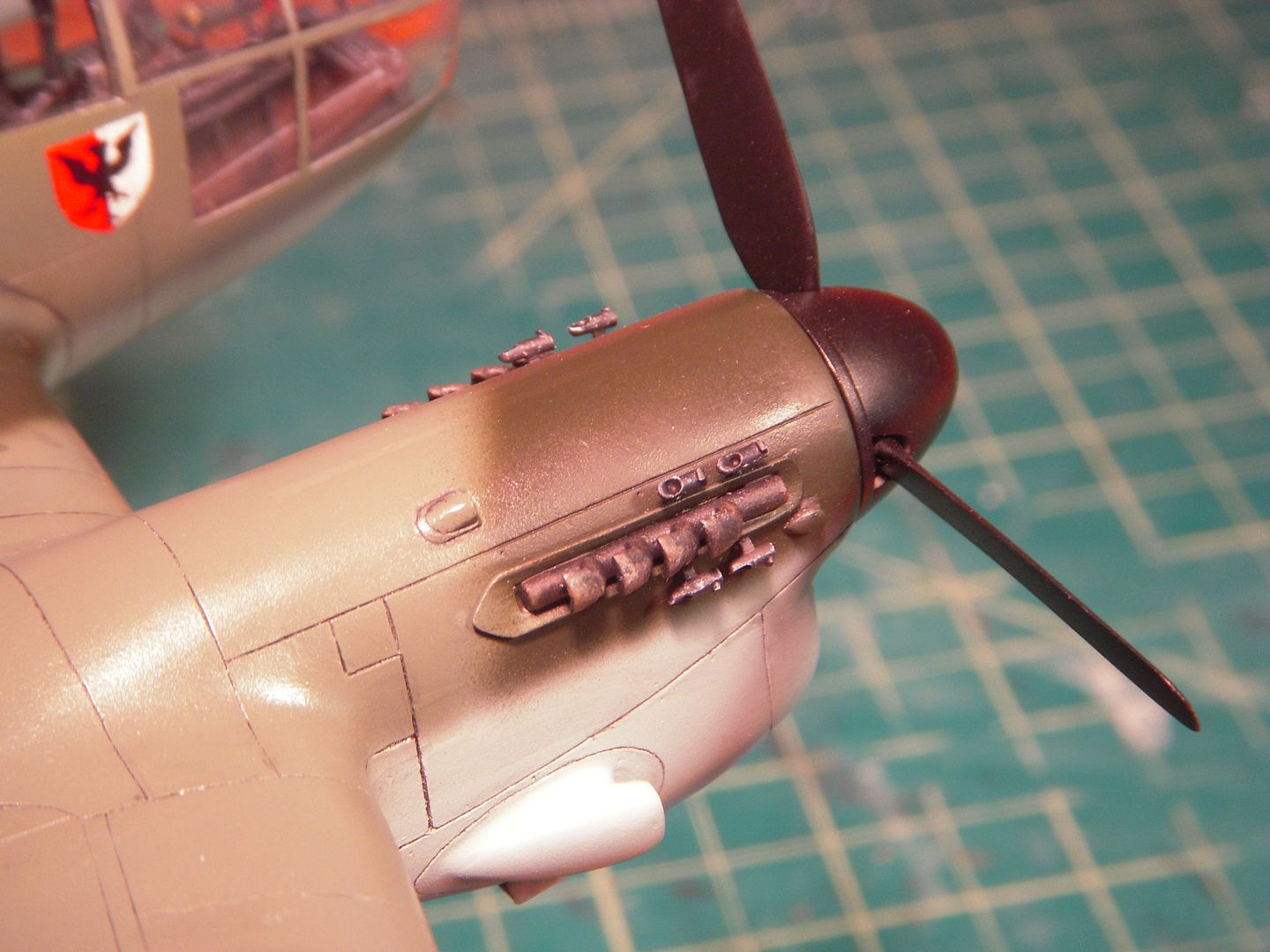

The conversion to the Merlins proved to be the most intensive part of the conversion. The Merlin cowling has a different cross section than the Junkers Jumo and the kit has the leading edge of the wing molded as part of the cowlings. My plan was to cut the Jumo cowlings off the fairings as close to the leading edges as possible fill the fairings with resin to give enough backing material to allow the nacelle to fair the Merlin profile into the wing leading edge.

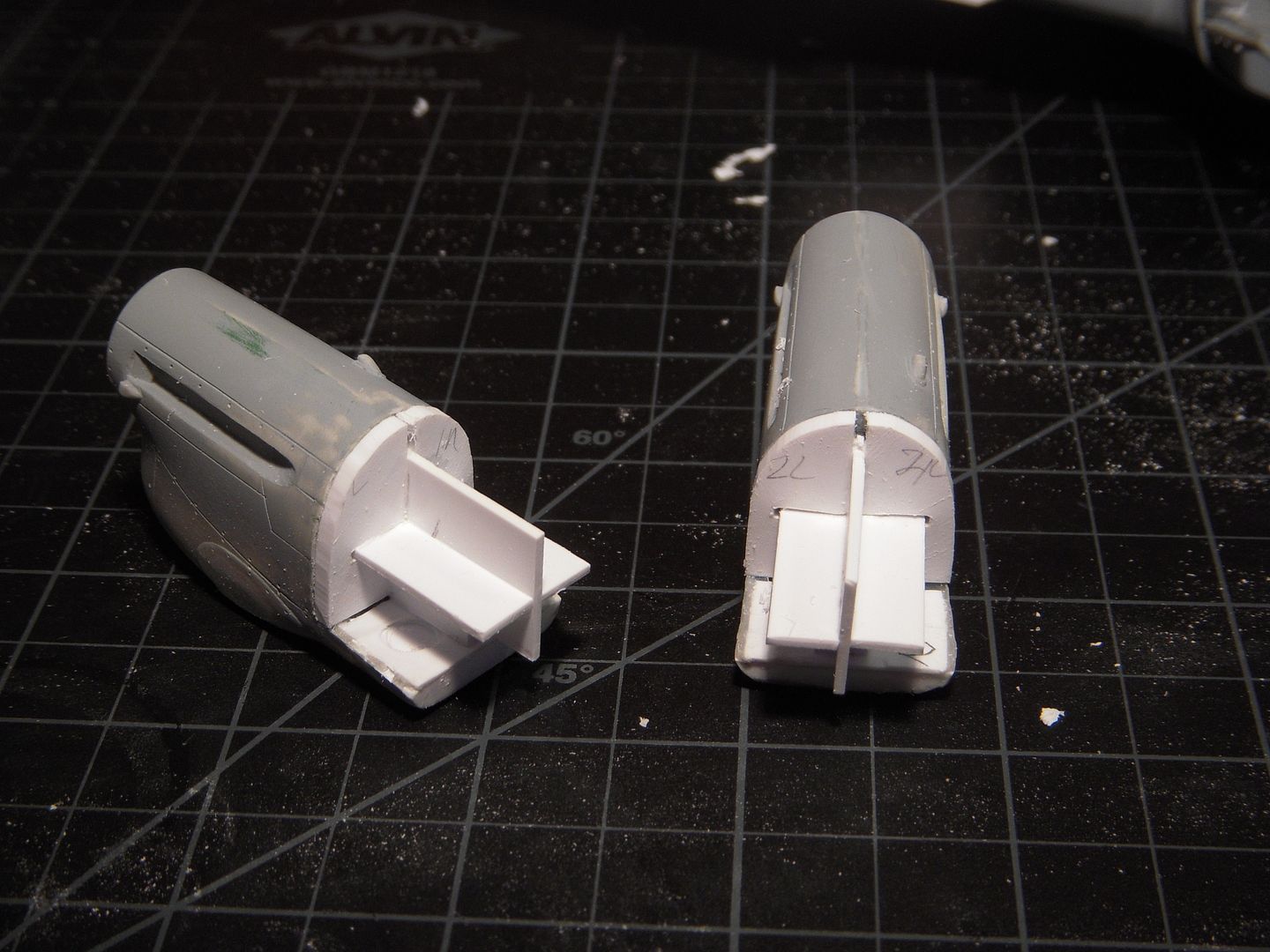

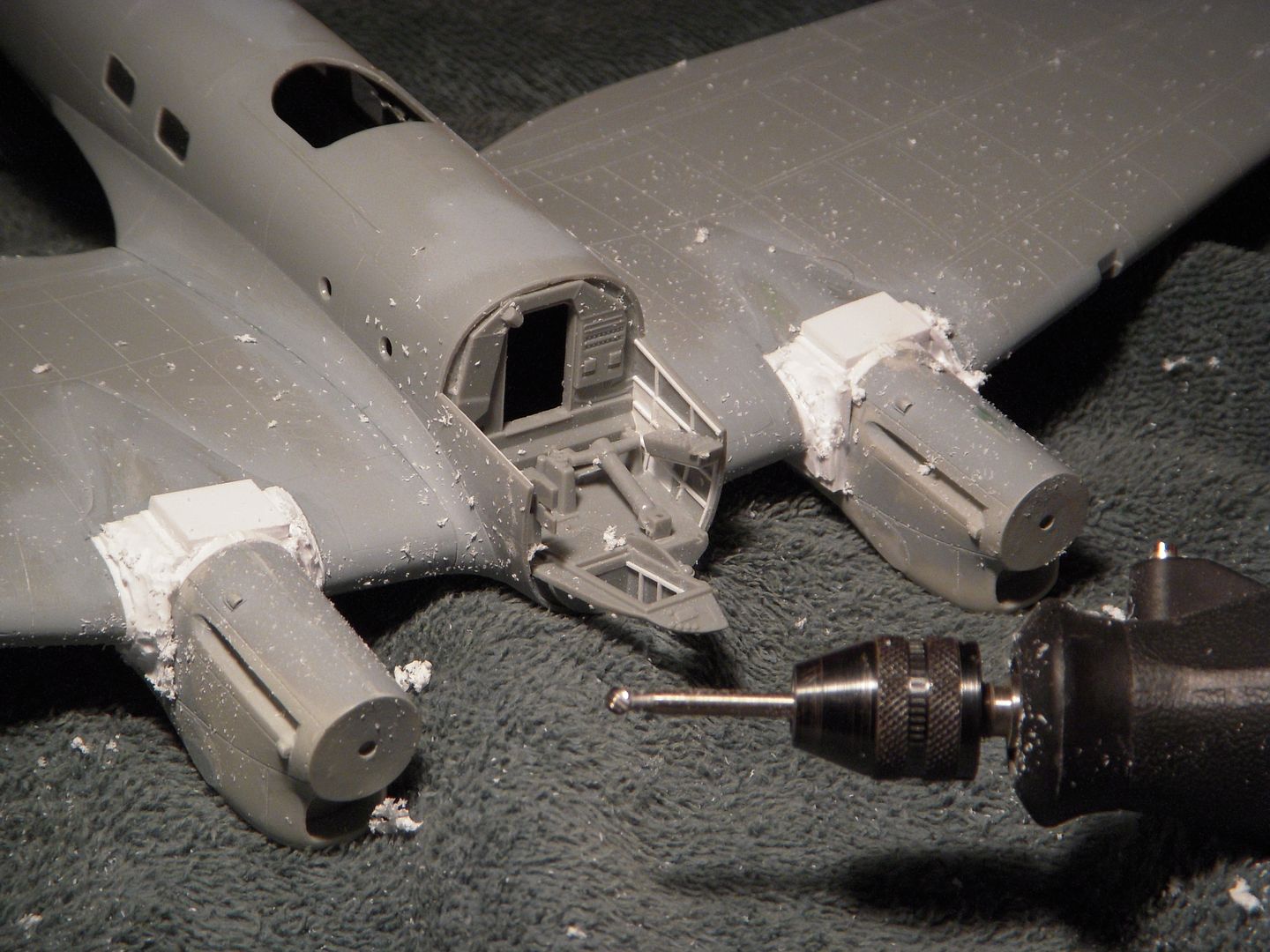

The Junkers Jumos removed.

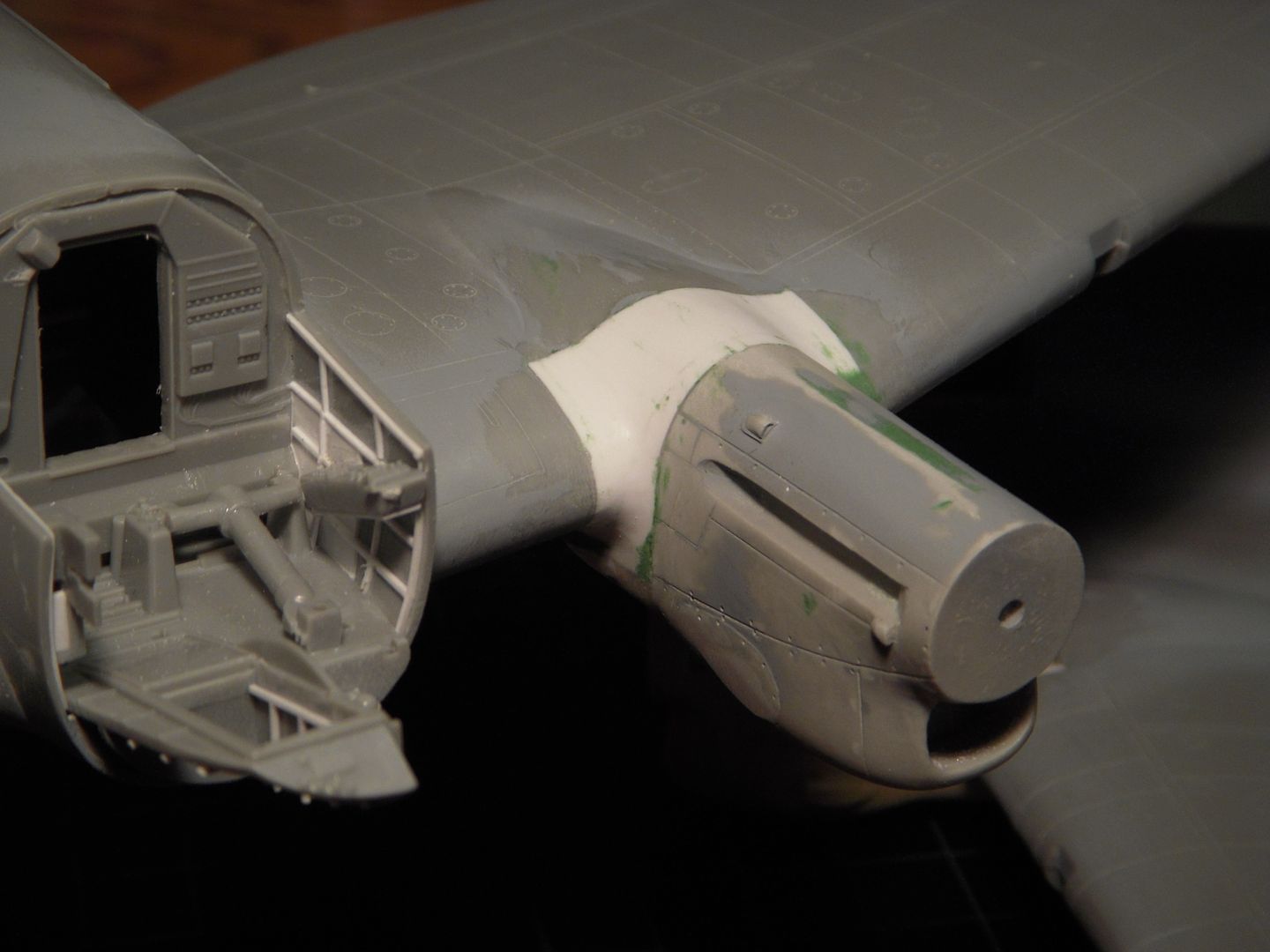

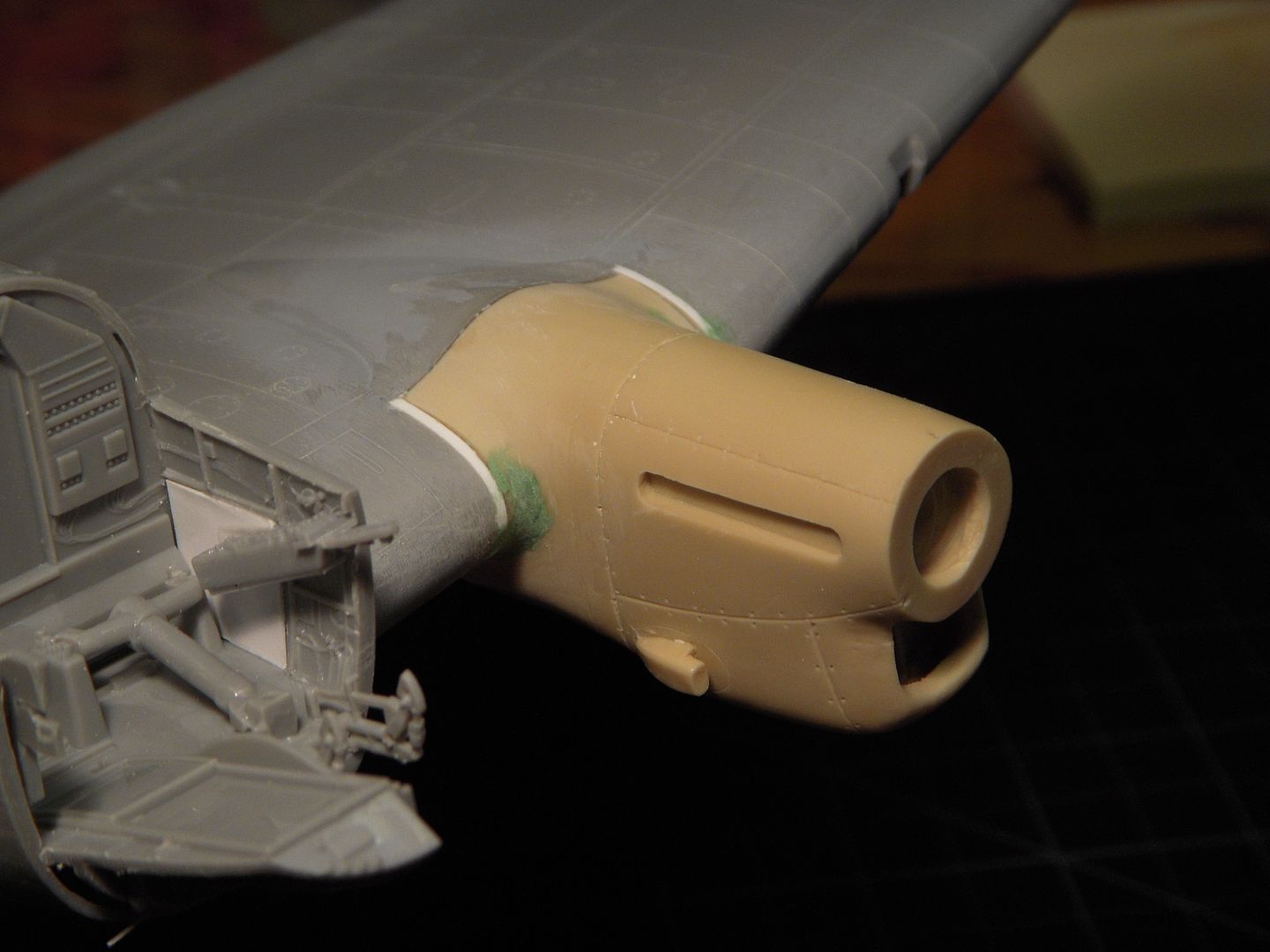

...the Merlins ready to be installed

Hmmm, not quite a perfect fit here!

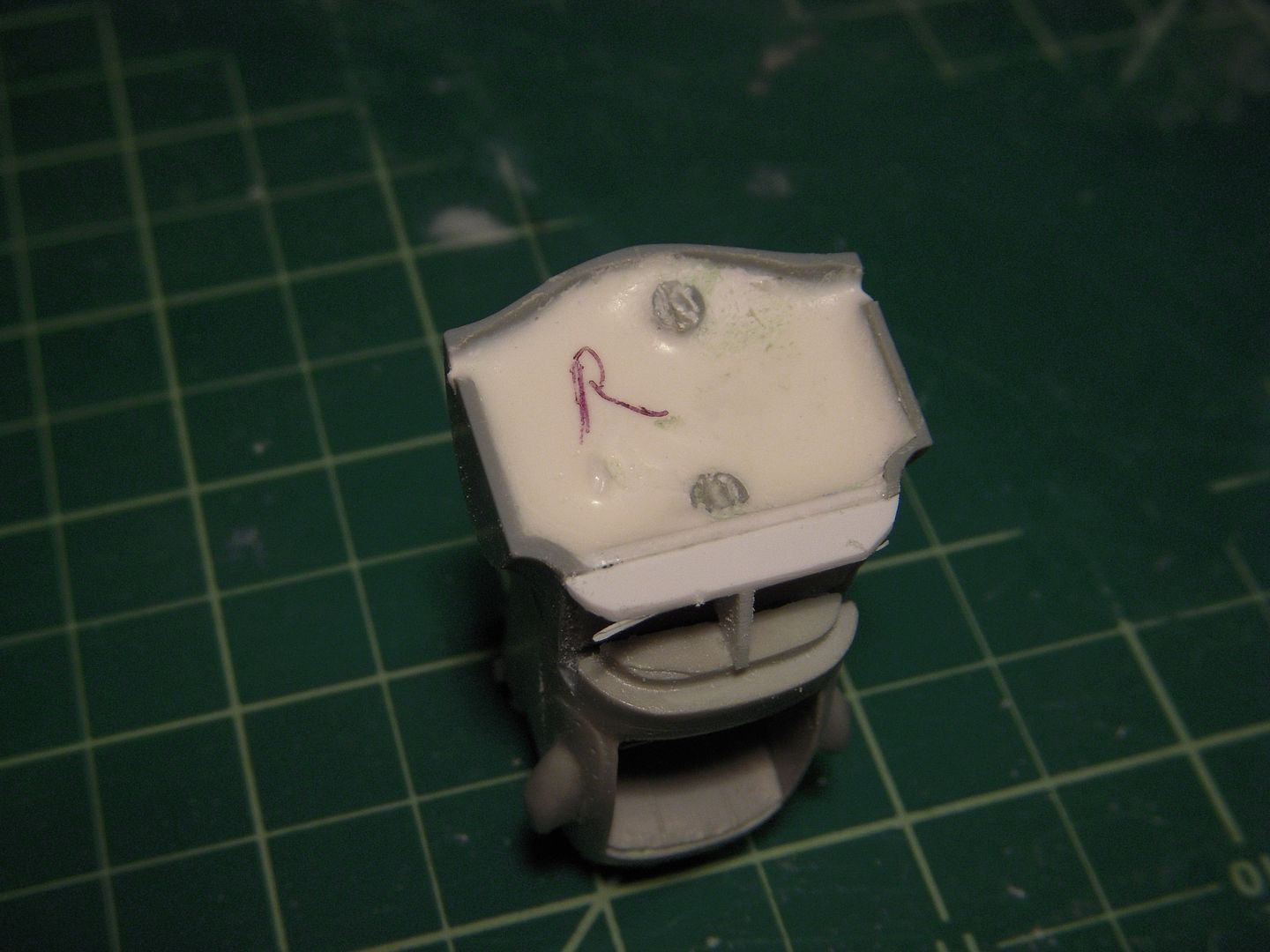

While making the measurements for the engine installation I noted a difference in the height of the wing so a bulkhead was fabricated to correct the discrepancy.

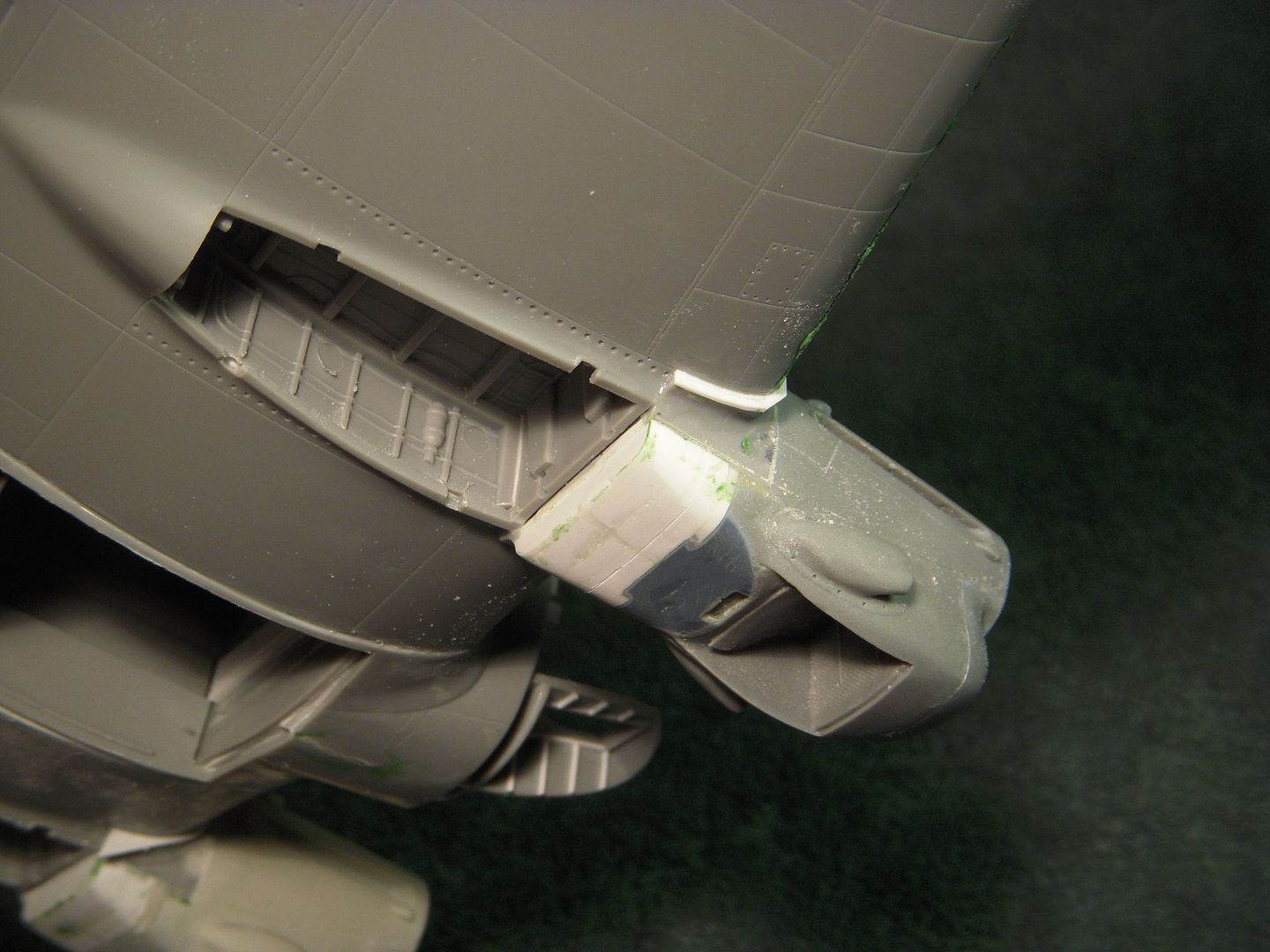

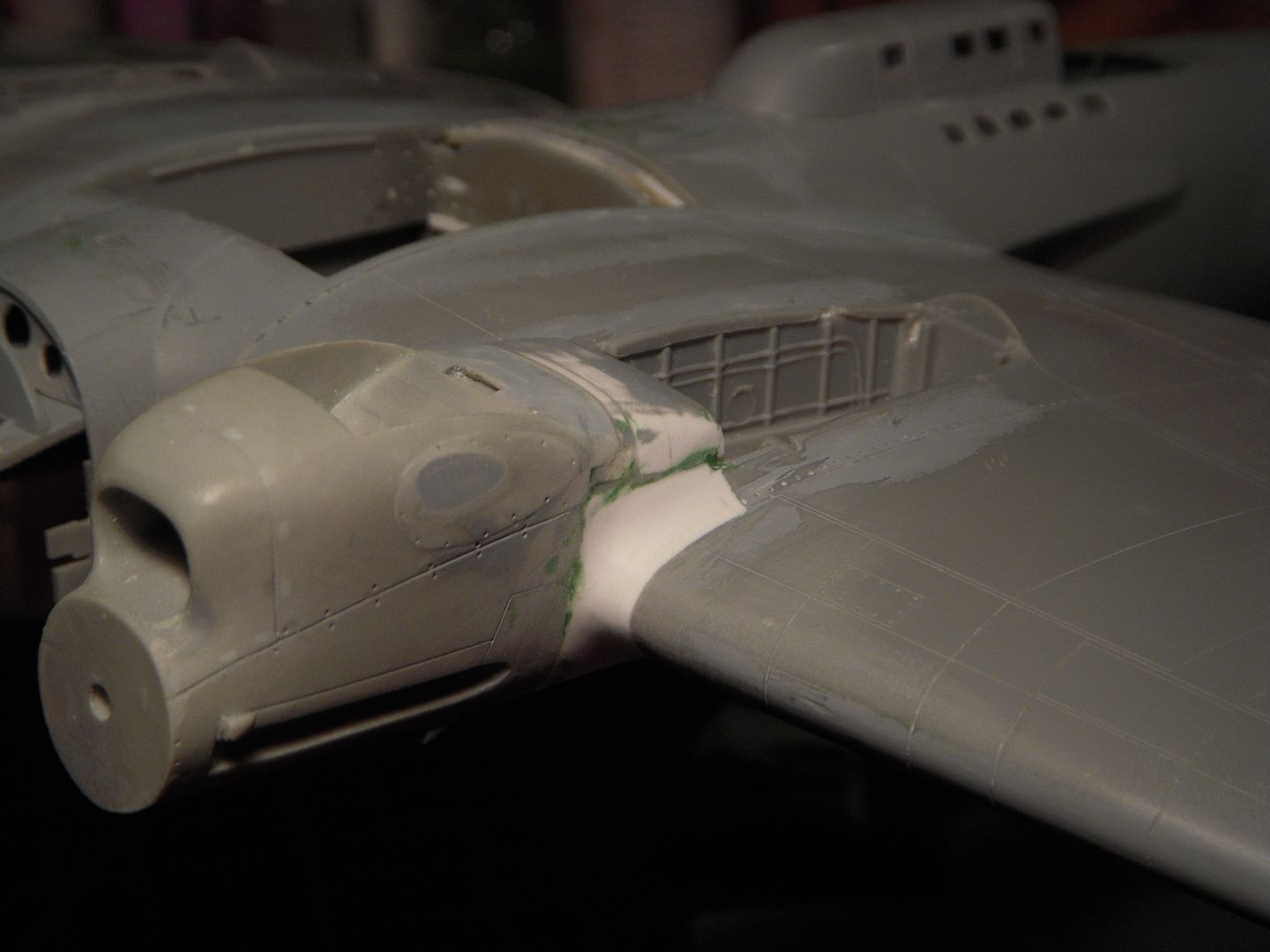

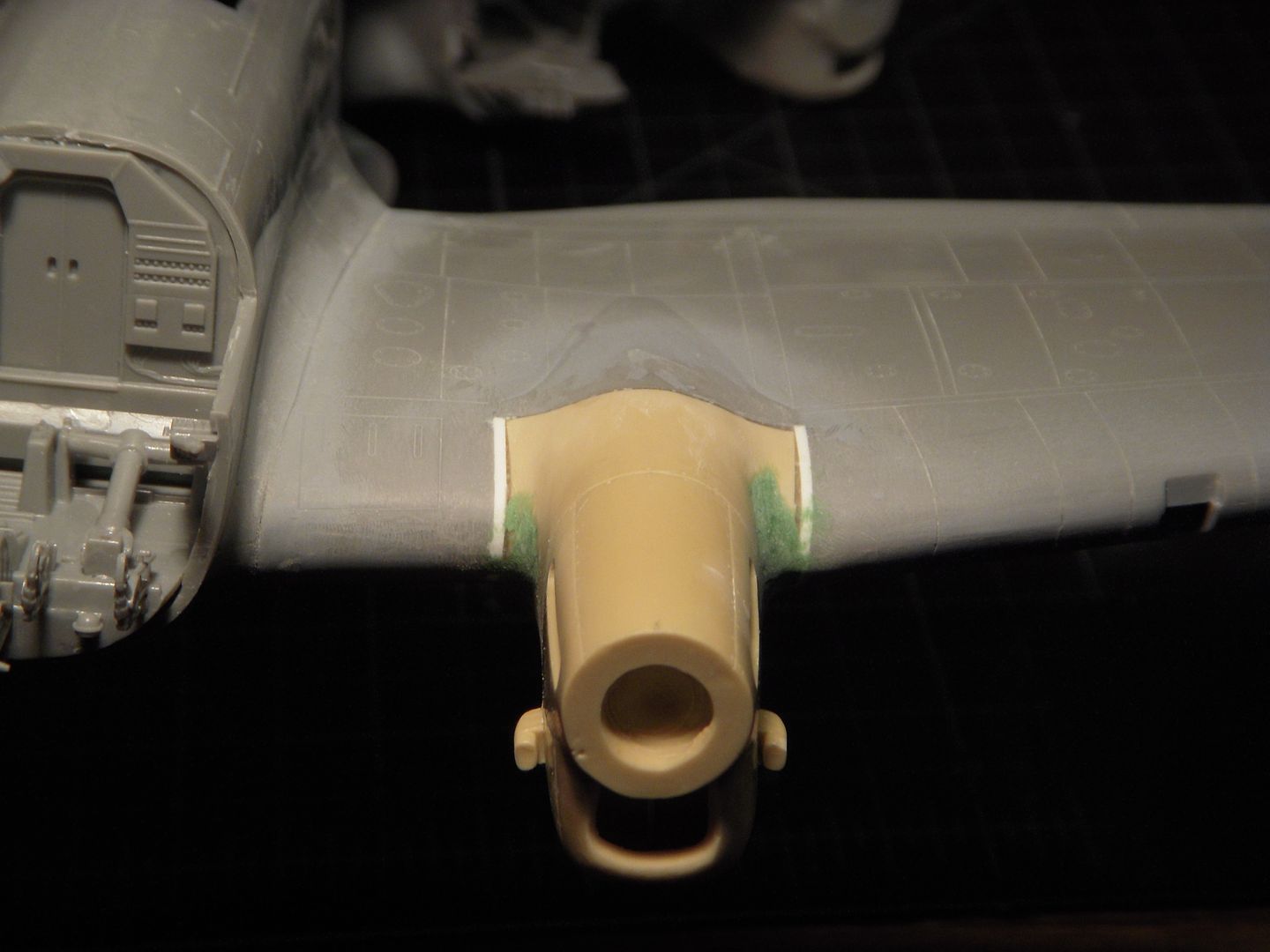

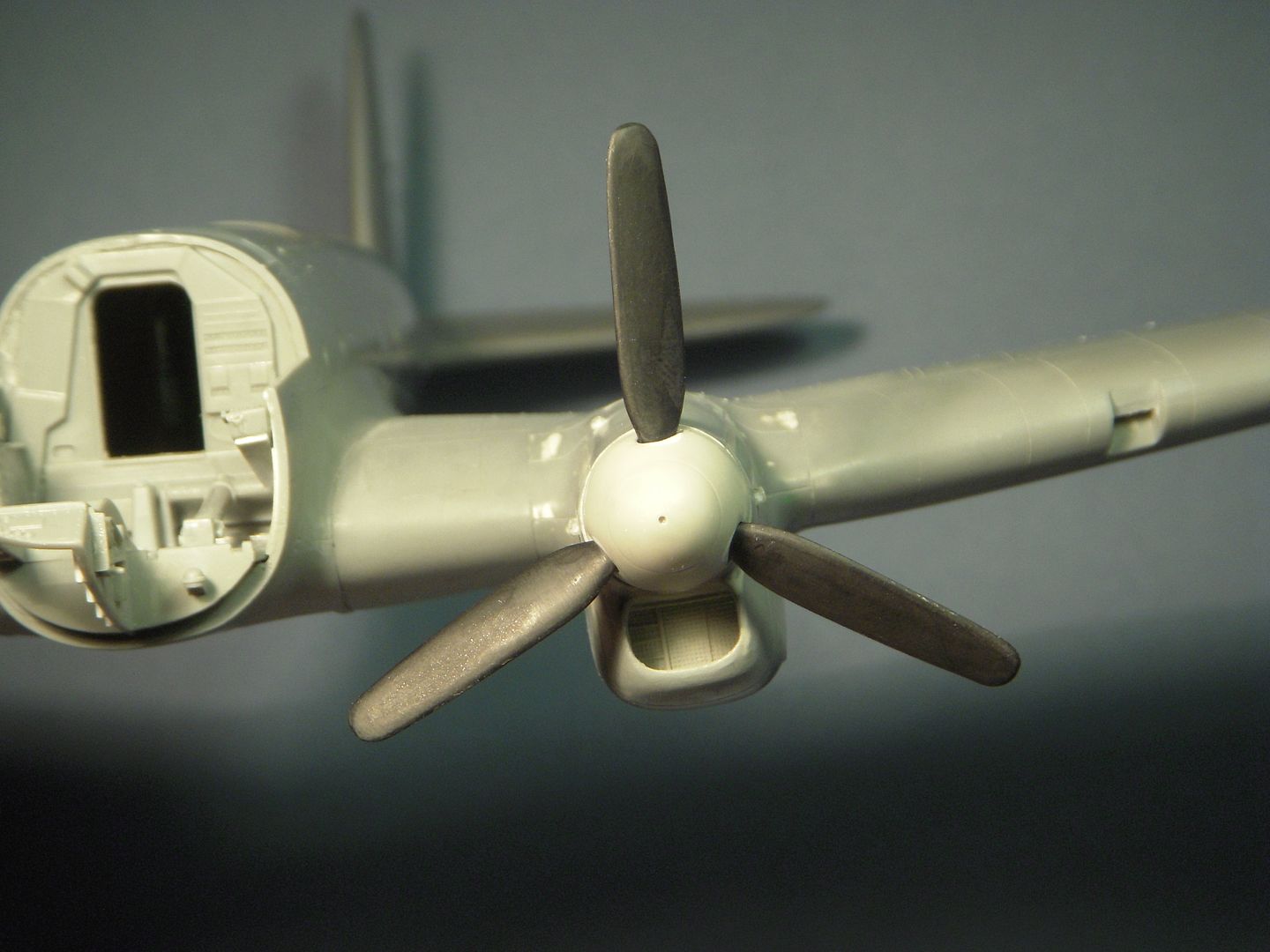

A bit of progress has been made. The engines have been installed and hopefully the the hardest part of the conversion is now behind. :yahoo: As it was obvious a lot of shaping would be required to fair the Merlins into the section of the wing leading edge I needed to add material to the inside of the nacelle. After gluing the resin engines into the plastic nacelle, I set the assembly on end and filled the back of the unit with casting resin. When this cured, out came the trusty Dremel tool and files and the nacelle shaped. The aft lower section of the nacelle then needed to match the contour of the front of the main landing gear doors. A bulkhead that matched the gear doors was attached to the aft end of the nacelle to be used as a guide. Filler blocks of styrene were glued into the gaps and once again the Dremel and files used to carve the unit to shape. Much measuring and trimming than ensued to get the engines properly positioned in 3 directions and 3 rotations! After 2 work sessions of fiddling about I took the plunge tonight and attached the units. :banghead: The final result appears to be reasonably successful. With the addition of the Merlins the distinctive CASA 2.111 shape becomes apparent. The process was actually easier to see and do than describe, hopefully the pictures should clear up any confusion! :huh: Eric F

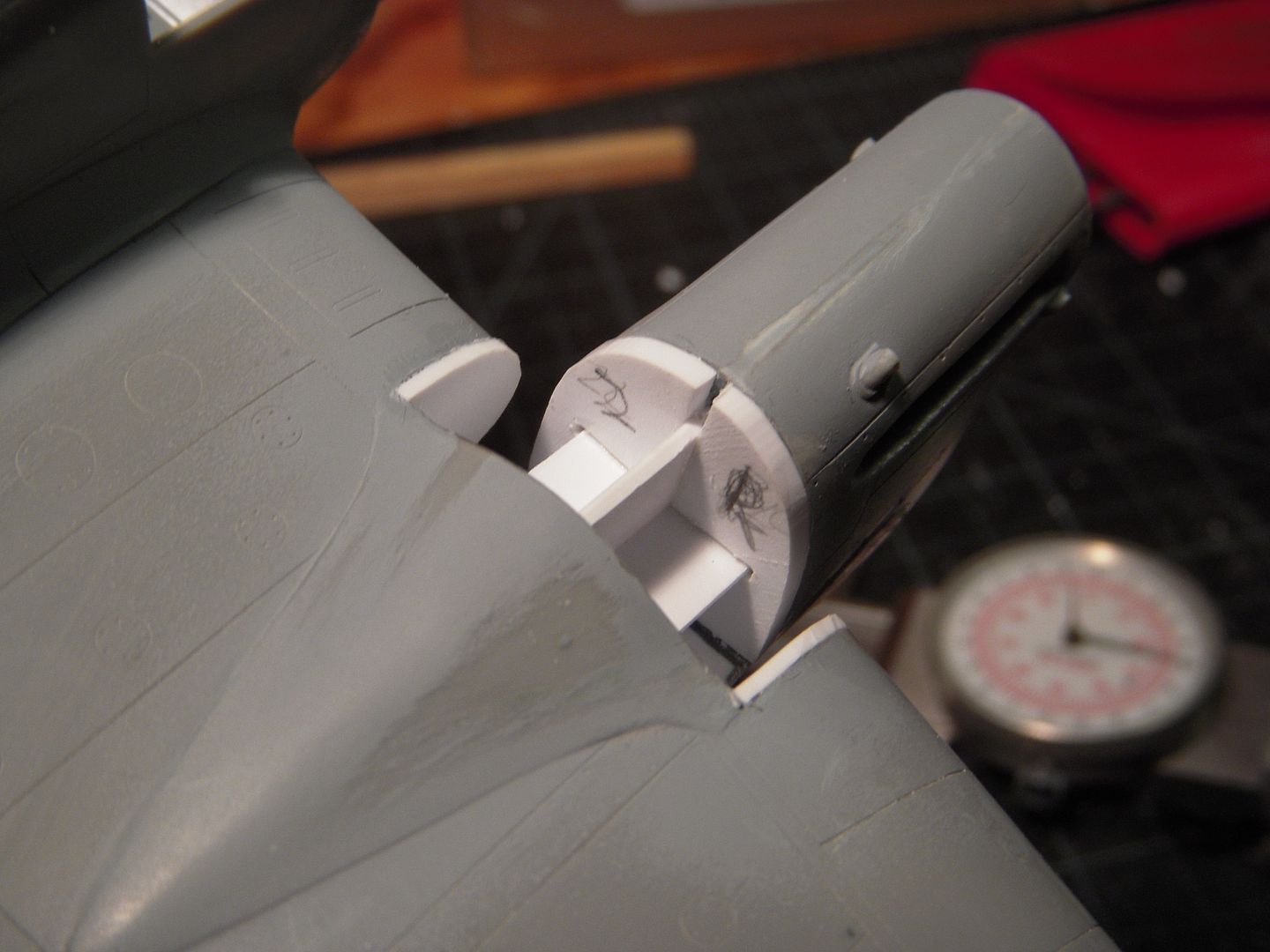

Bulkheads added as guides to the final desired contour

After the styrene filler blocks, lots of plastic shavings later, emerged the final nacelle shape!

Much measuring and fitting to get the installation in proper orientation

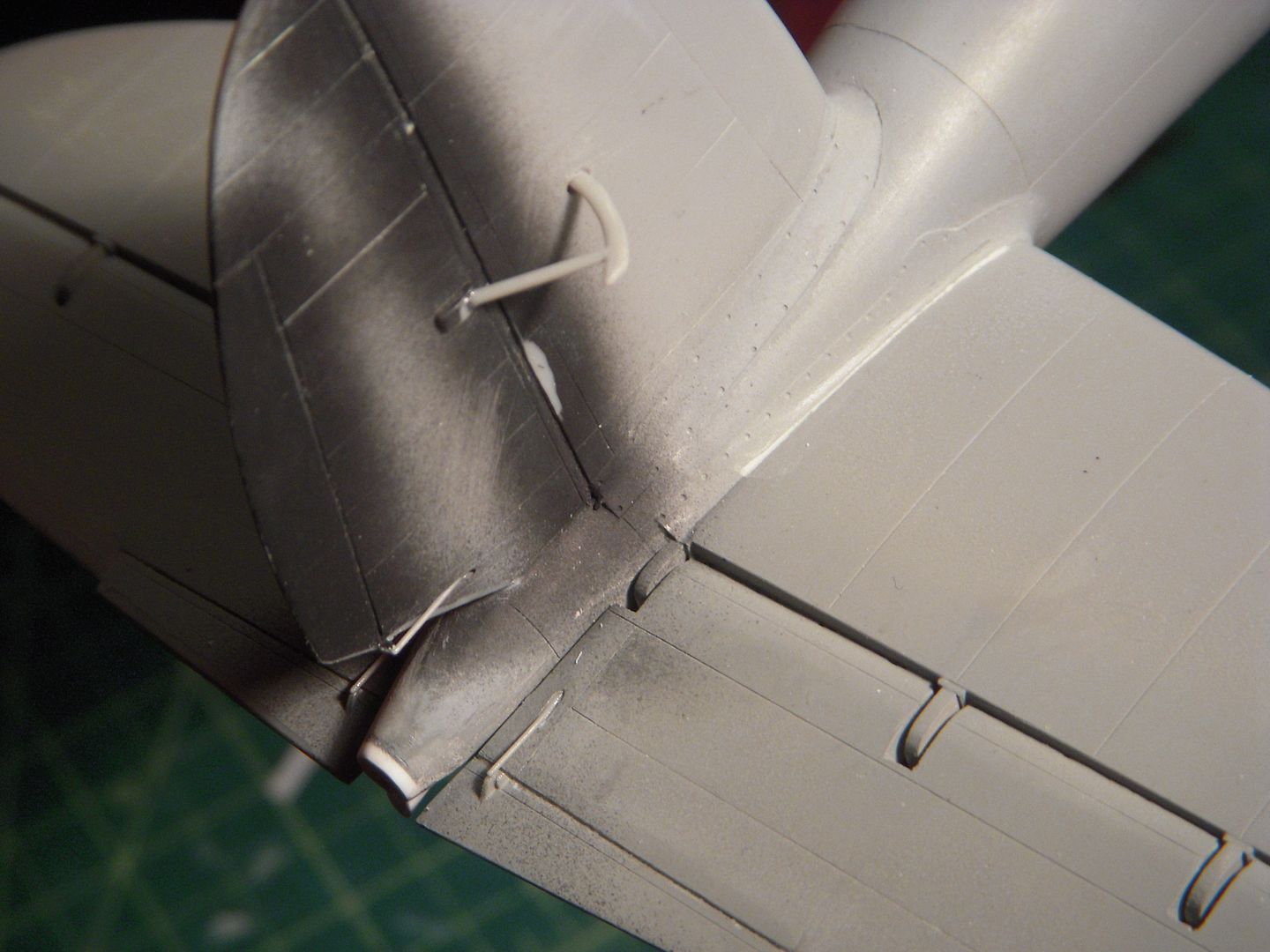

A fairly major setback has happened! After the engine nacelles were installed and the final shaping, sanding and scribing completed, the project left alone for a couple days (work keeps getting in the way of modeling!) After I returned, I noticed a few small soft, bubbled areas, almost like too much plastic solvent was used and oozed out. I dug out the softened areas and filled the resulting holes with super glue, sanded and re-scribed. I then went to work on the tail, dropping the elevators for interest and making the prominent hinges.

As time passed, more of the soft areas occurred on the nacelles. Each time thinking things were settling down, I repeated the process of digging out, filling, sanding and re-scribing. Tonight I found yet another new area and on close inspection found the plastic kit pieces that were in contact with the resin I used to fill were involved in a reaction and the soft areas were spreading. With no other choice, I got a grip on my emotions, out came the saw and I removed the entire nacelle unit from the wing!

I think I'll put the CASA's away for a bit to give myself a chance to cool down and concentrate on the Spitfire Mk XIV builds I have started. Here are a few pics of my minor disaster. Lesson learned: Do NOT use resin to fill plastic kit parts!

Here are a couple of pics, I was in the process of cleaning off the work desk and these are the remains of the wing leading edge section. The aftermarket Merlin engines are fine and I will reuse them.

The gooey layer covered at least 75% of the plastic in contact with the resin and most of the rest of the plastic parts had become pliable enough to bend without difficulty. The plastic rods I used to attach the engines into the leading edge fairing had a gooey layer also.

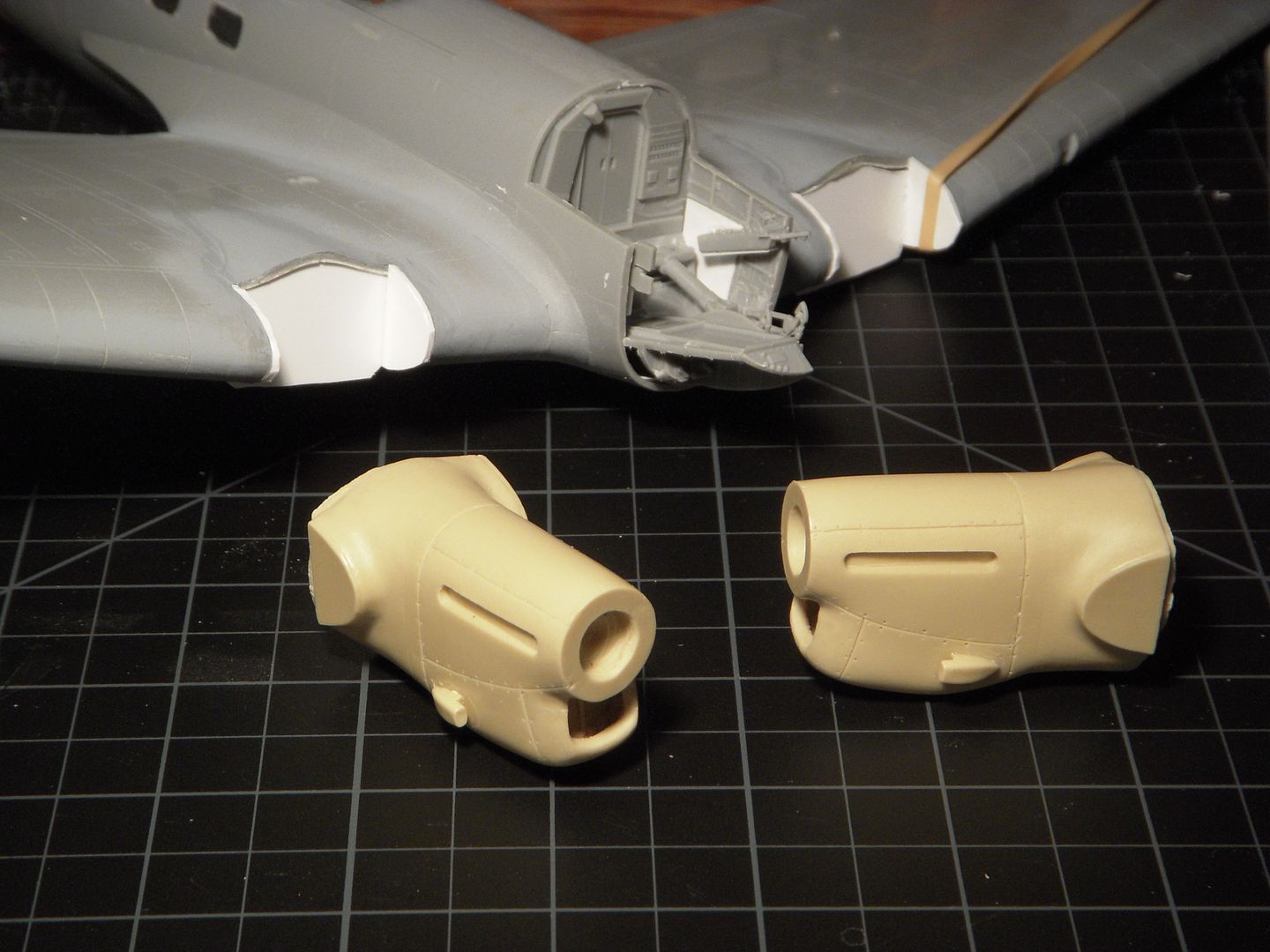

Belcher Bits engines more accurate for the CASAs but the conversion kit's engines had almost the same dimensions, thank you to my benefactor John M! Although the fit of the conversion kit to the wing was going to take some work, I had a pretty good shape to start.<br />

Now to attach the engine and to replace the leading edge/nacelle fairings on the second CASA. I boxed in the recess in the wing with styrene, this providing a solid base. A cross shaped slot was cut into the back of the resin engine cowling and a matching styrene mount was epoxied into the slots. Much measuring and aligning followed and the mount was cut, filed and glued tg the boxed section in the wing. The next step is to fill in the gaps with styrene block and get to carving!<br />

At least the project is moving forward again! Eric F.<br />

[img]http://i1115.photobucket.com/albums/k550/modelpicposter/CASA%202%20111/DSCN6092.jpg)

slots cut to accept the styrene mounts

Mounts in, braced and ready to be trimmed.

A lot of measuring and trimming went on to get to this stage!

The conversion kit parts have pretty good outline and shape but...

... require a bit of work to achieve proper fit!

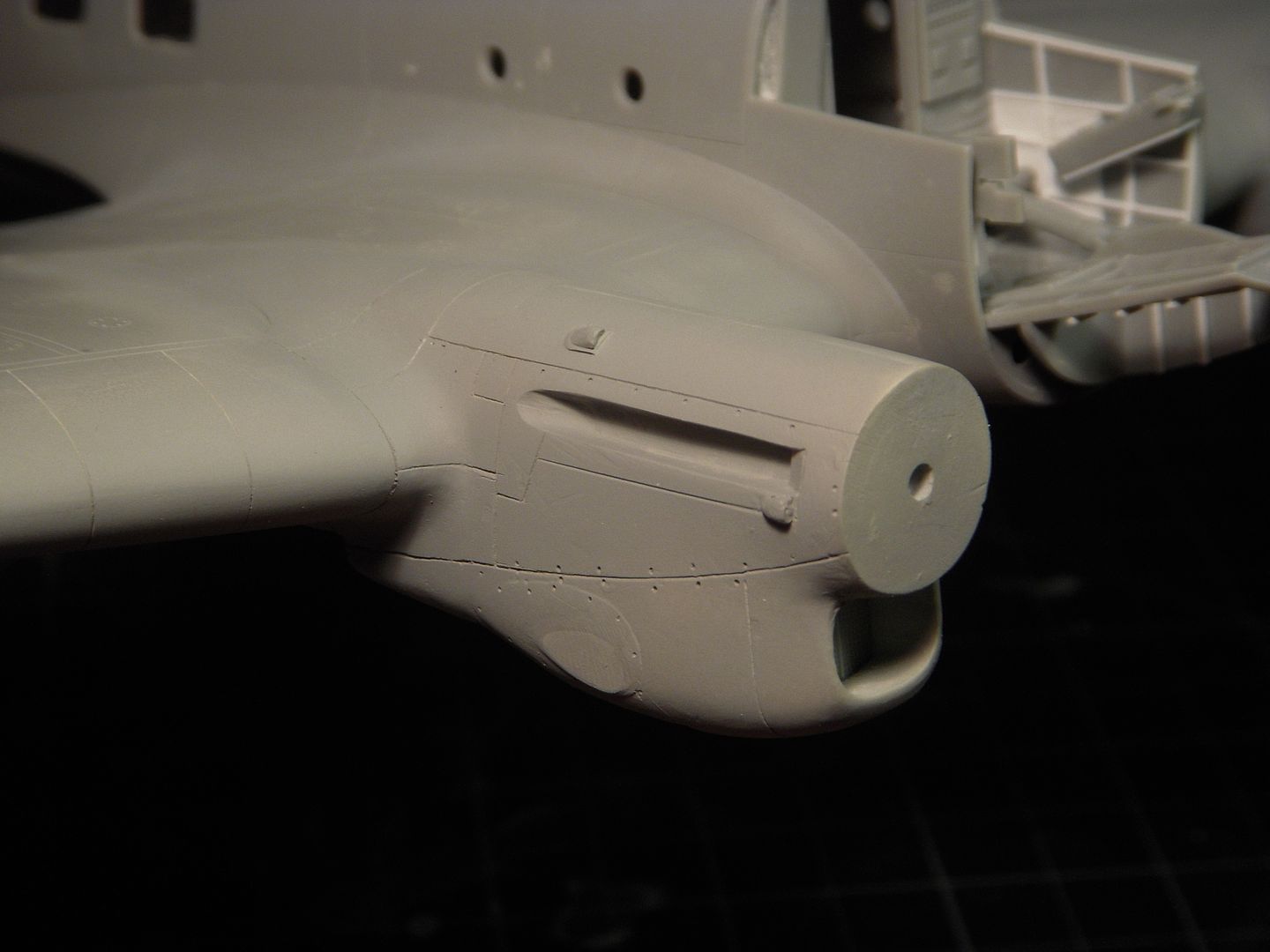

A quick update for those who are still following this epic drama! A bit of motortool and file work that produced an impressive amount of plastic dust (I had to vacuum myself off!) the repair work to the nacelle is complete. I just need to do a bit of scribing and then I can get back to working on the cockpits.

Styrene blocks glued in place

Tools of the trade, coarse...

...and fine

Finally the end result, not perfect but close enough!

The resin conversion kit parts were a bit easier!

That's all for now!

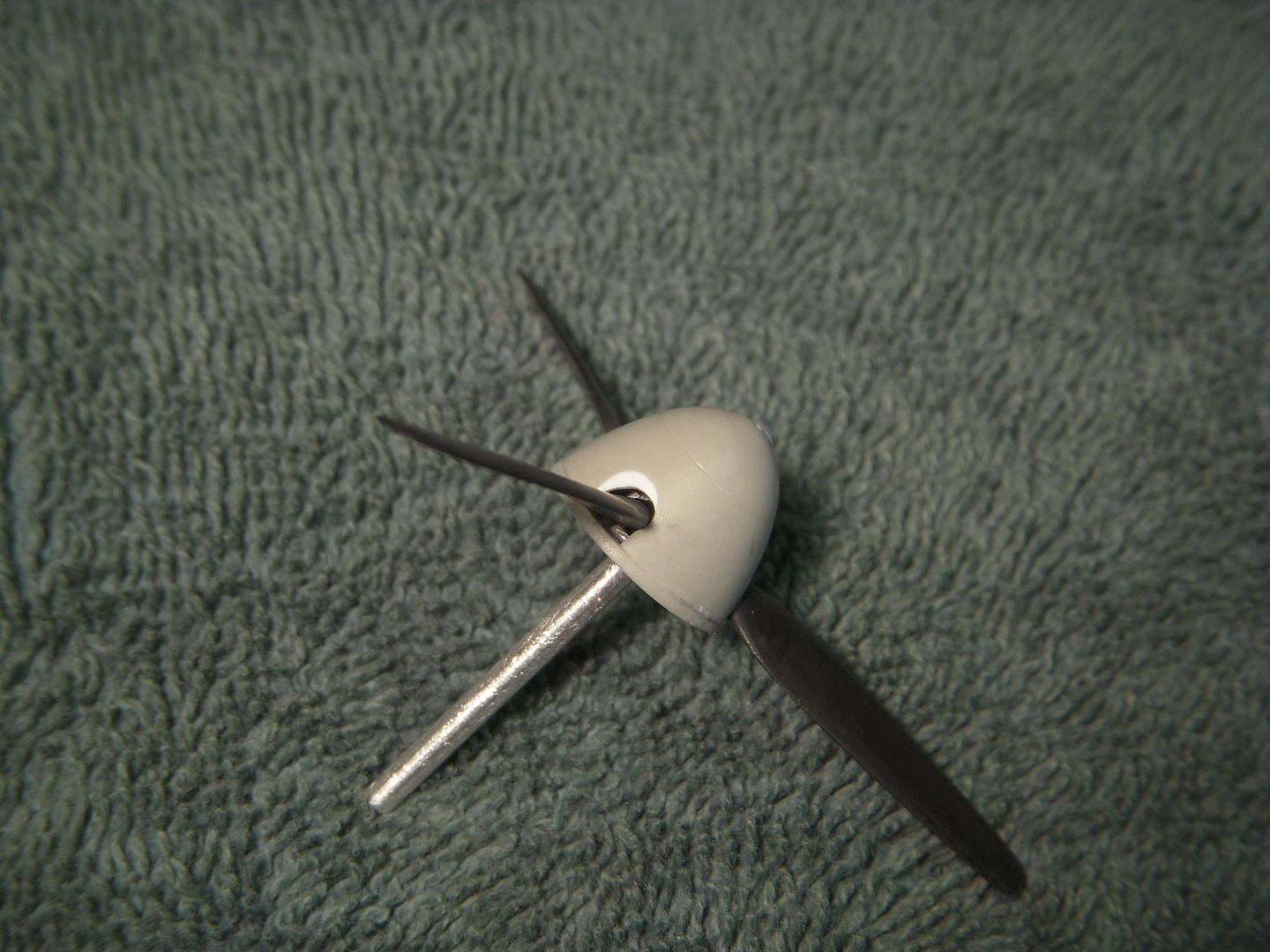

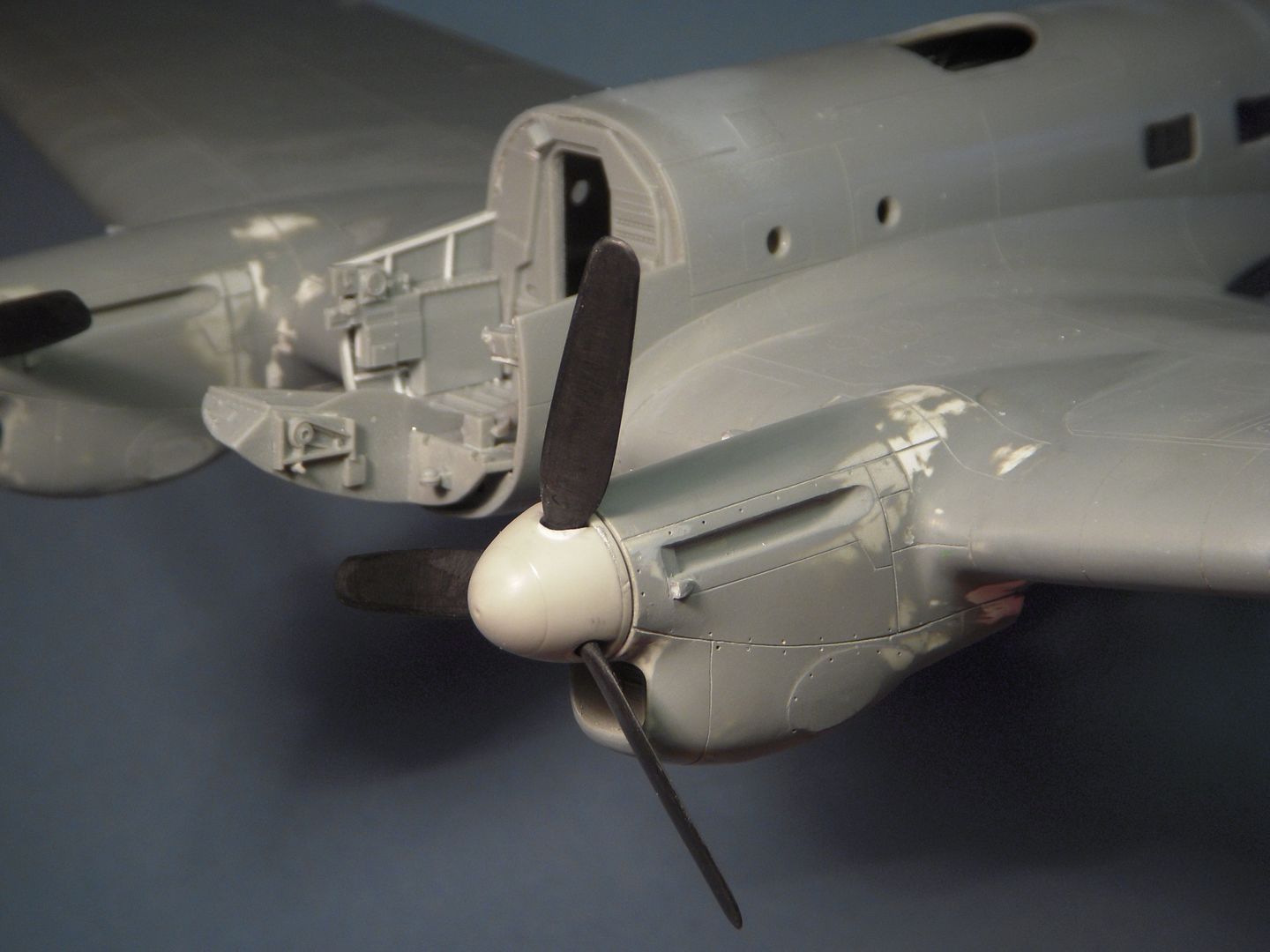

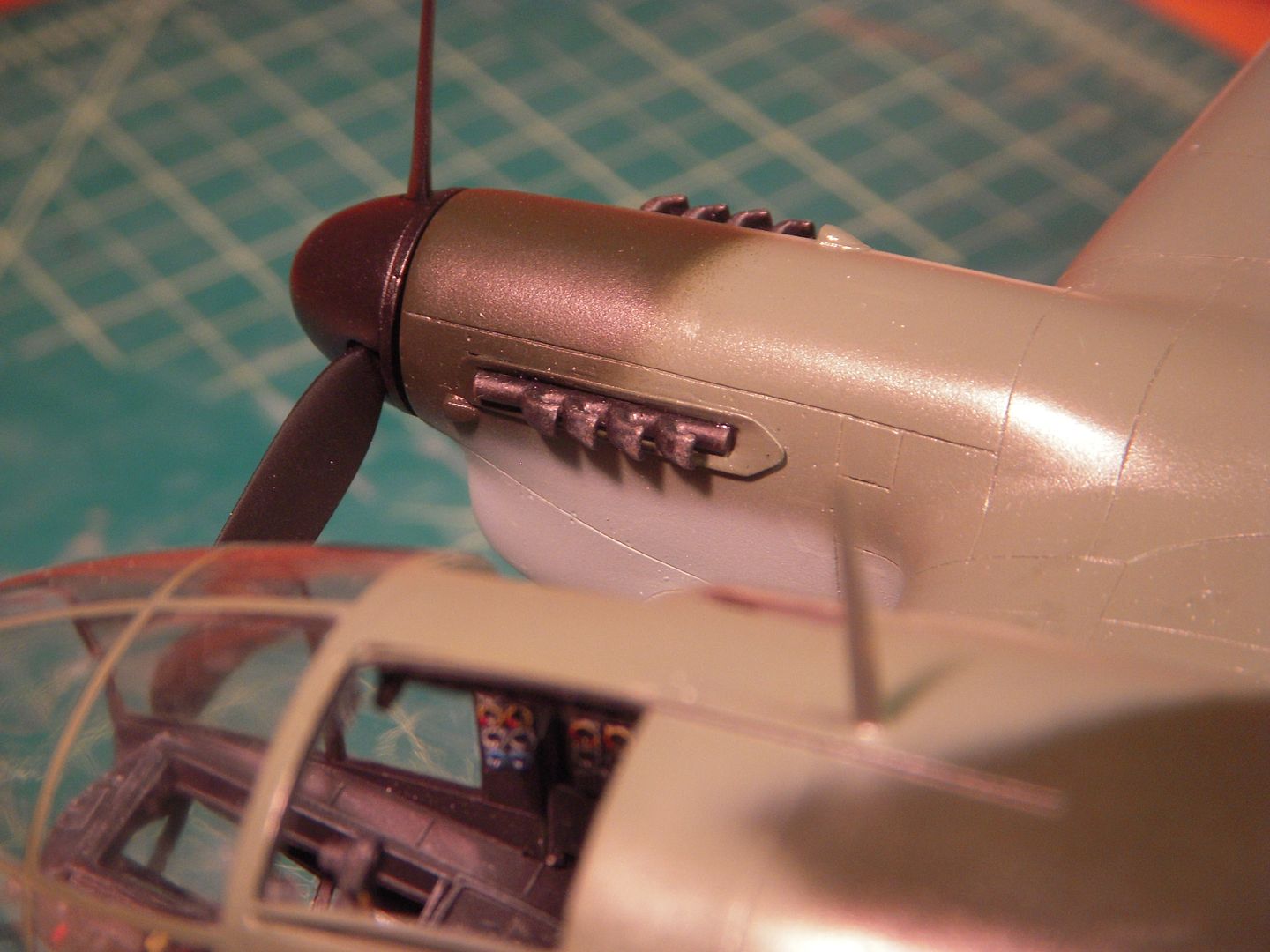

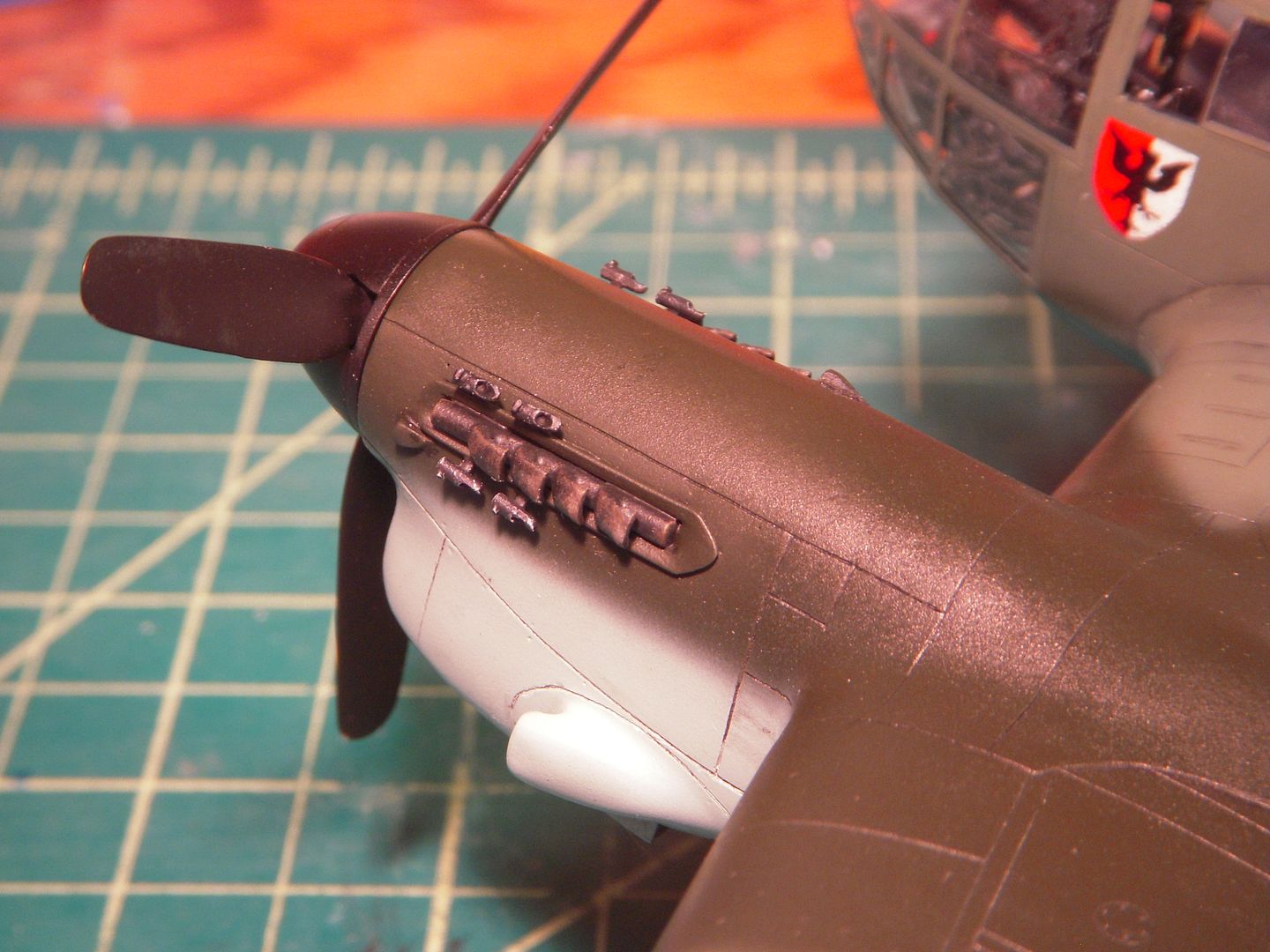

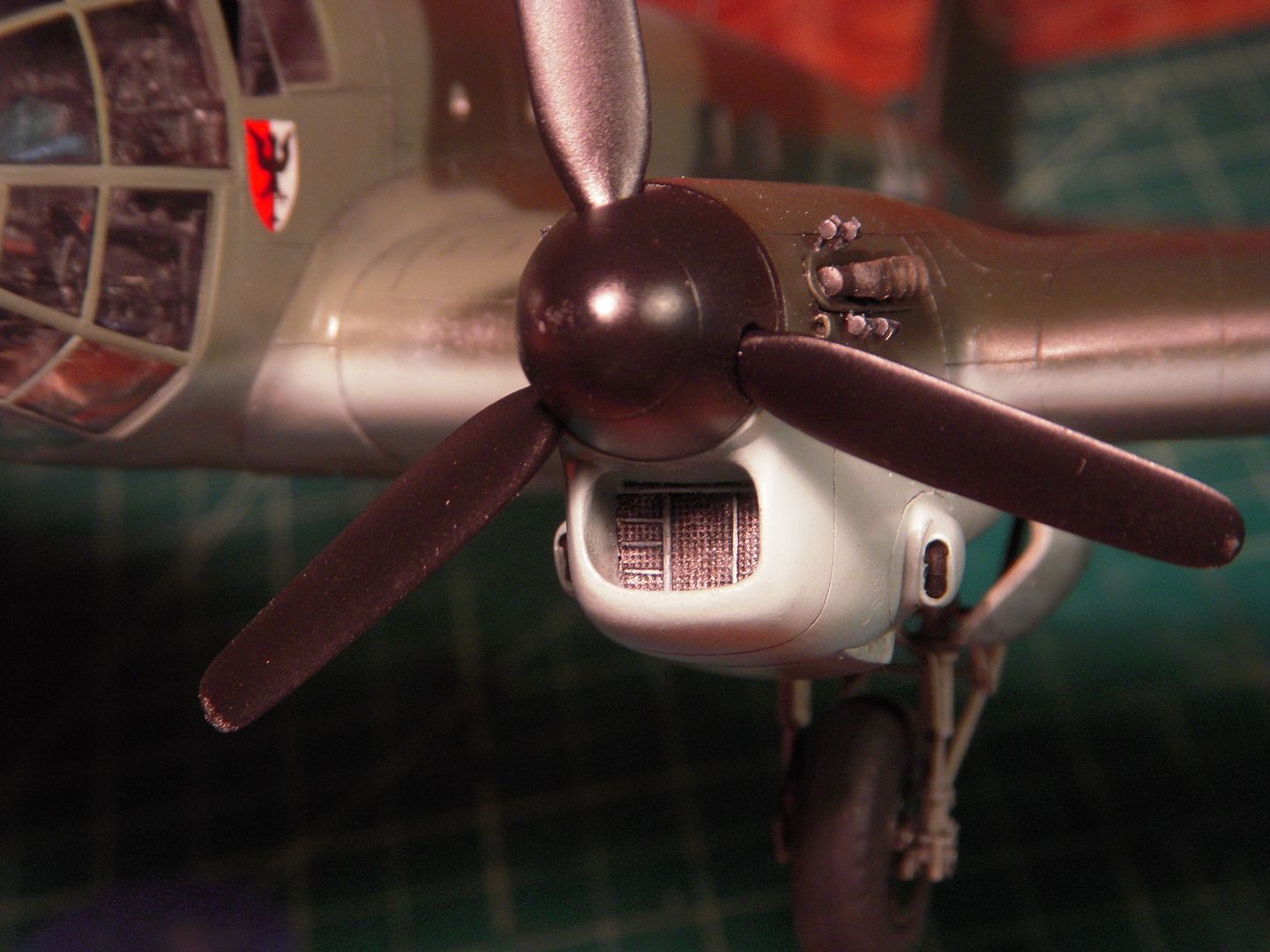

It's been a busy couple of weeks so time for just a quick update to let you know the project is (as usual) creeping forward. Got the nacelles fine sanded, scribed and primed. So far they're looking ok. I got the props built up out of parts from the spare parts box, Hamilton Standard props off a B-17G and spinners from late model Me-109s. A bit of reshaping was needed but the result looks reasonably close to my reference pics.

Next: on to the cockpits!

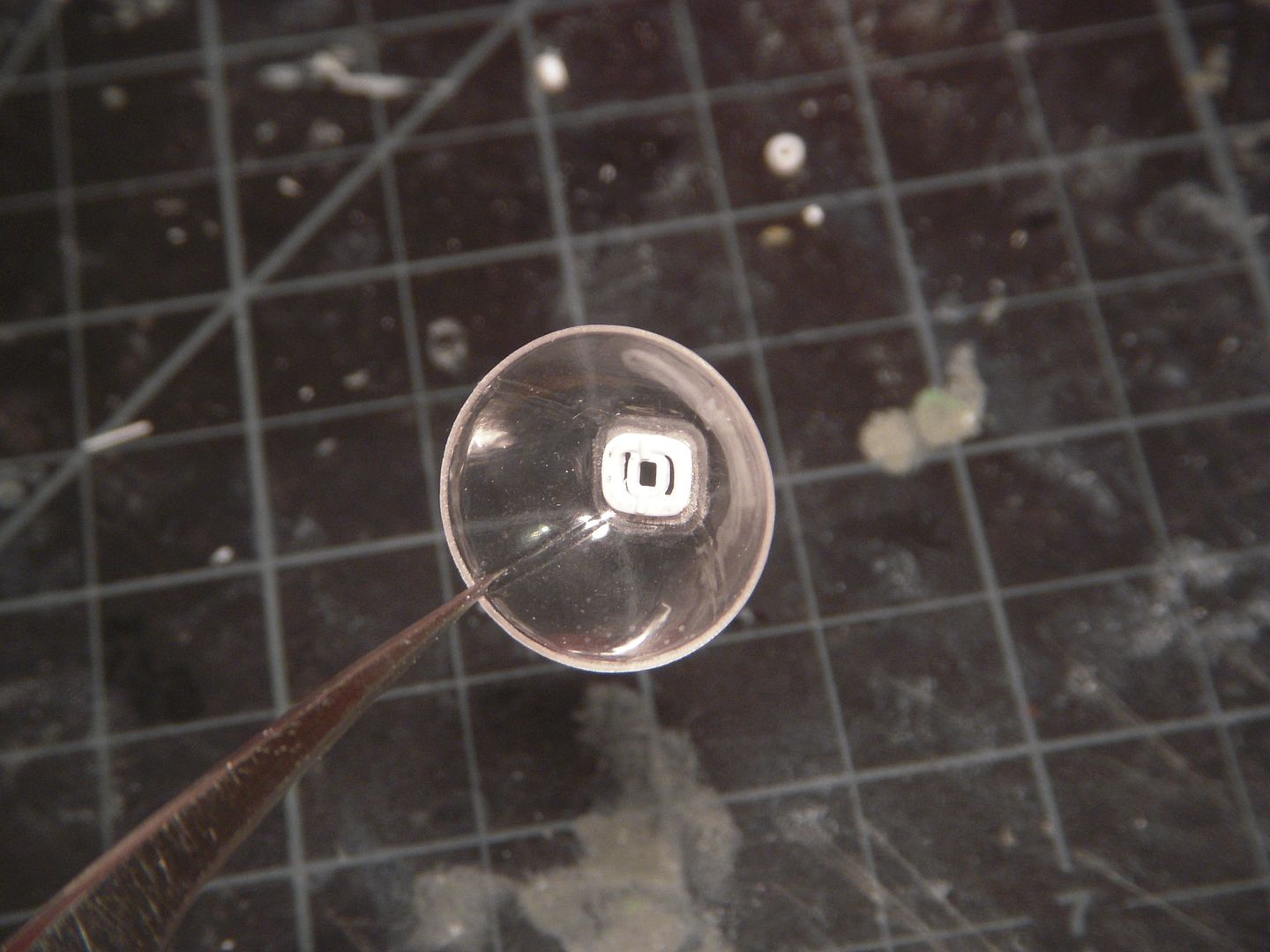

The openings in the spinners needed to be closed up a little and reshaped.

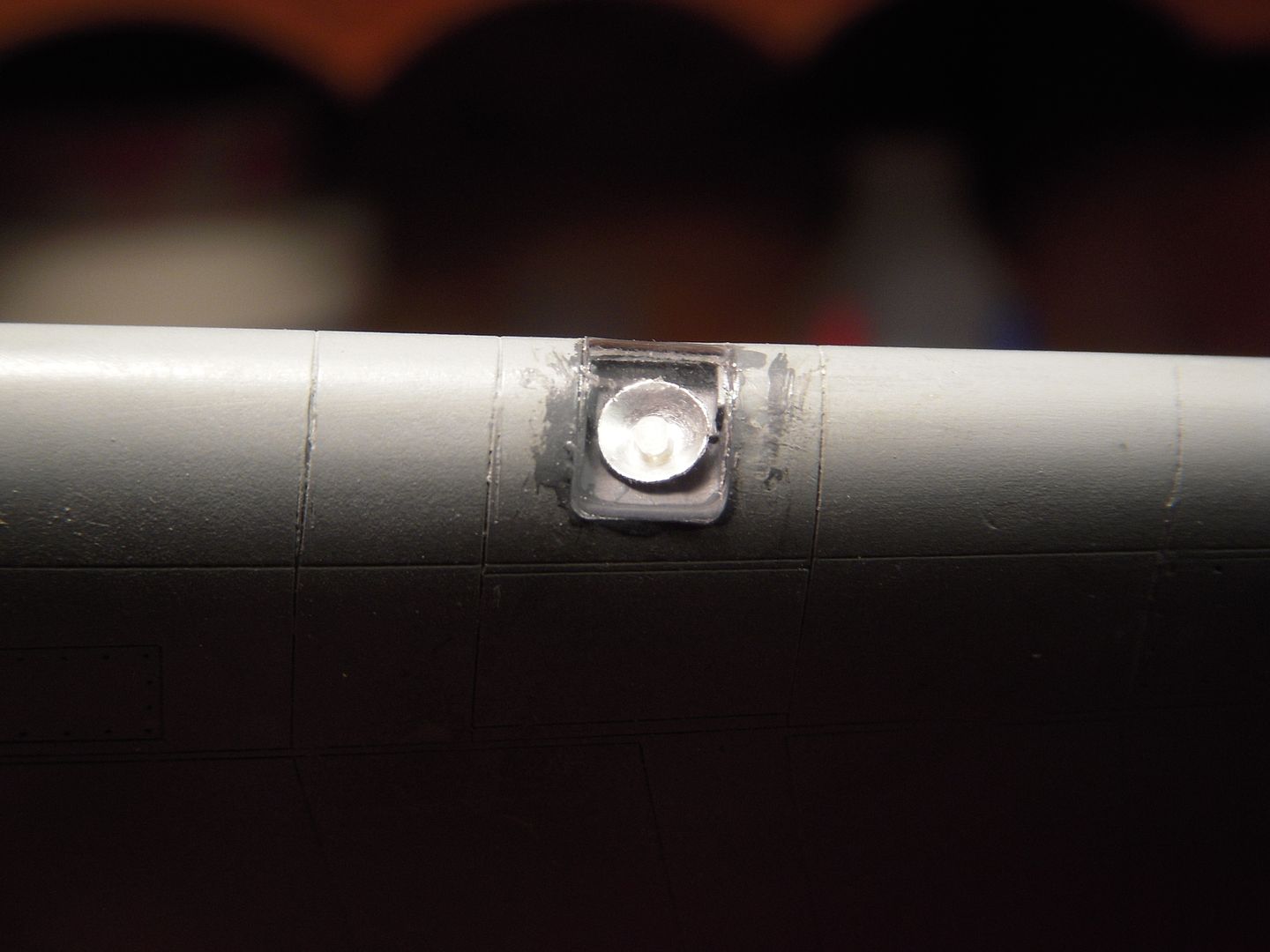

The nacelles were drilled so a matching tube could be epoxied in and accept the aluminum tube propeller shaft.

Did not get as much done on the projects as I thought, (THERE'S something new!) but I promised to get some pics up this weekend. I'll get a better write-up on the processes used in the next update. Hope you haven't gotten bored yet, there's still a long way to go!

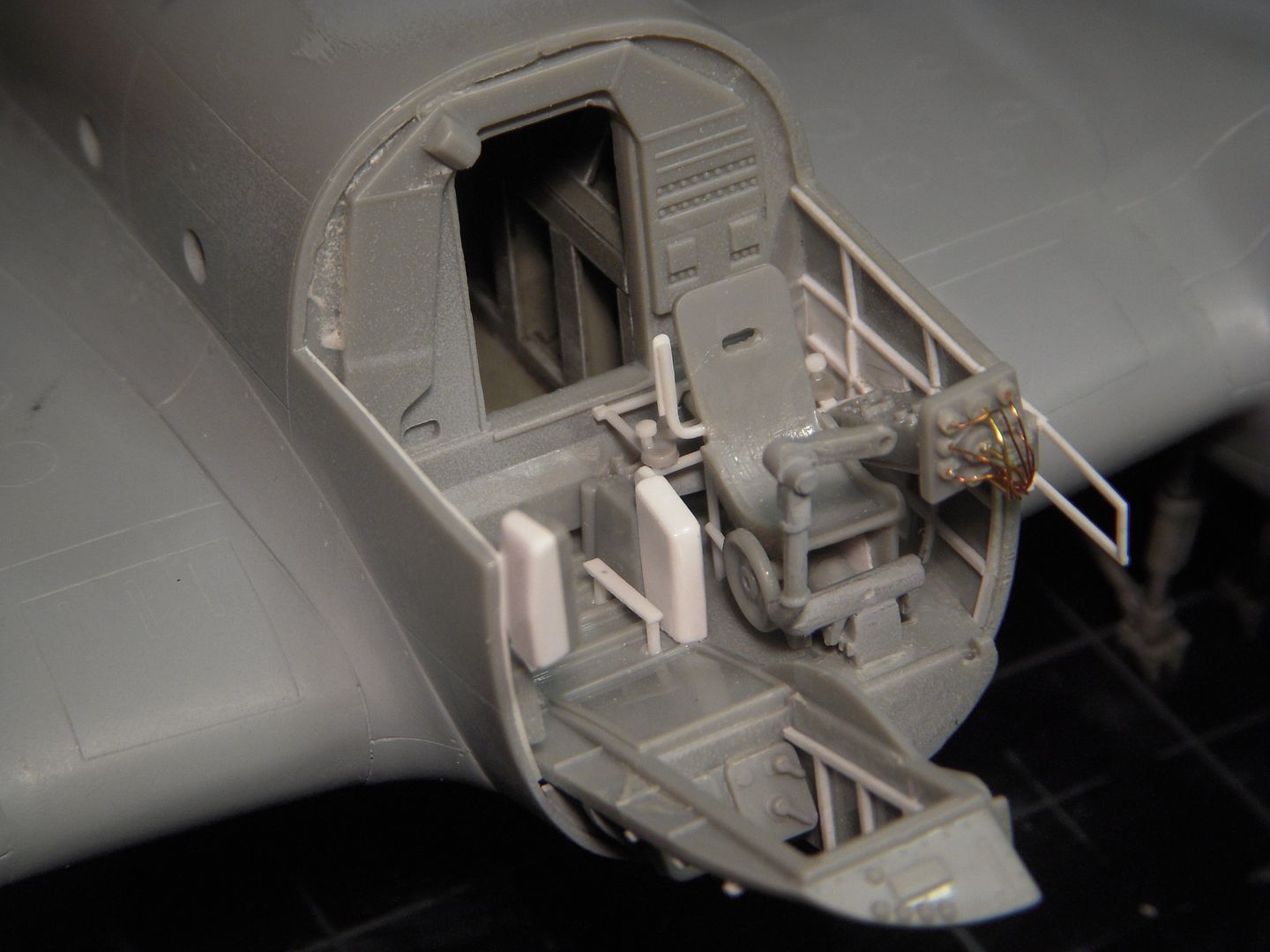

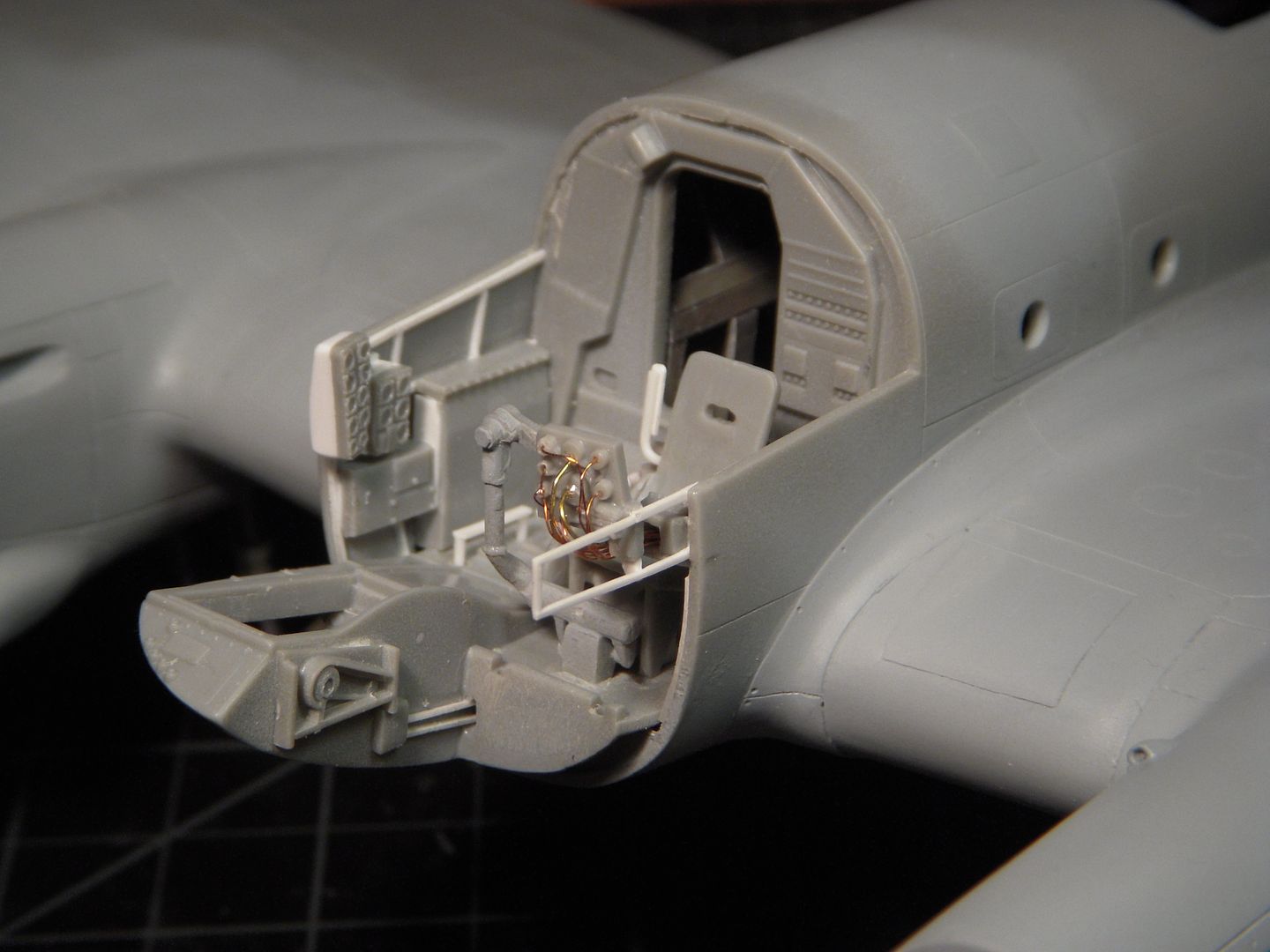

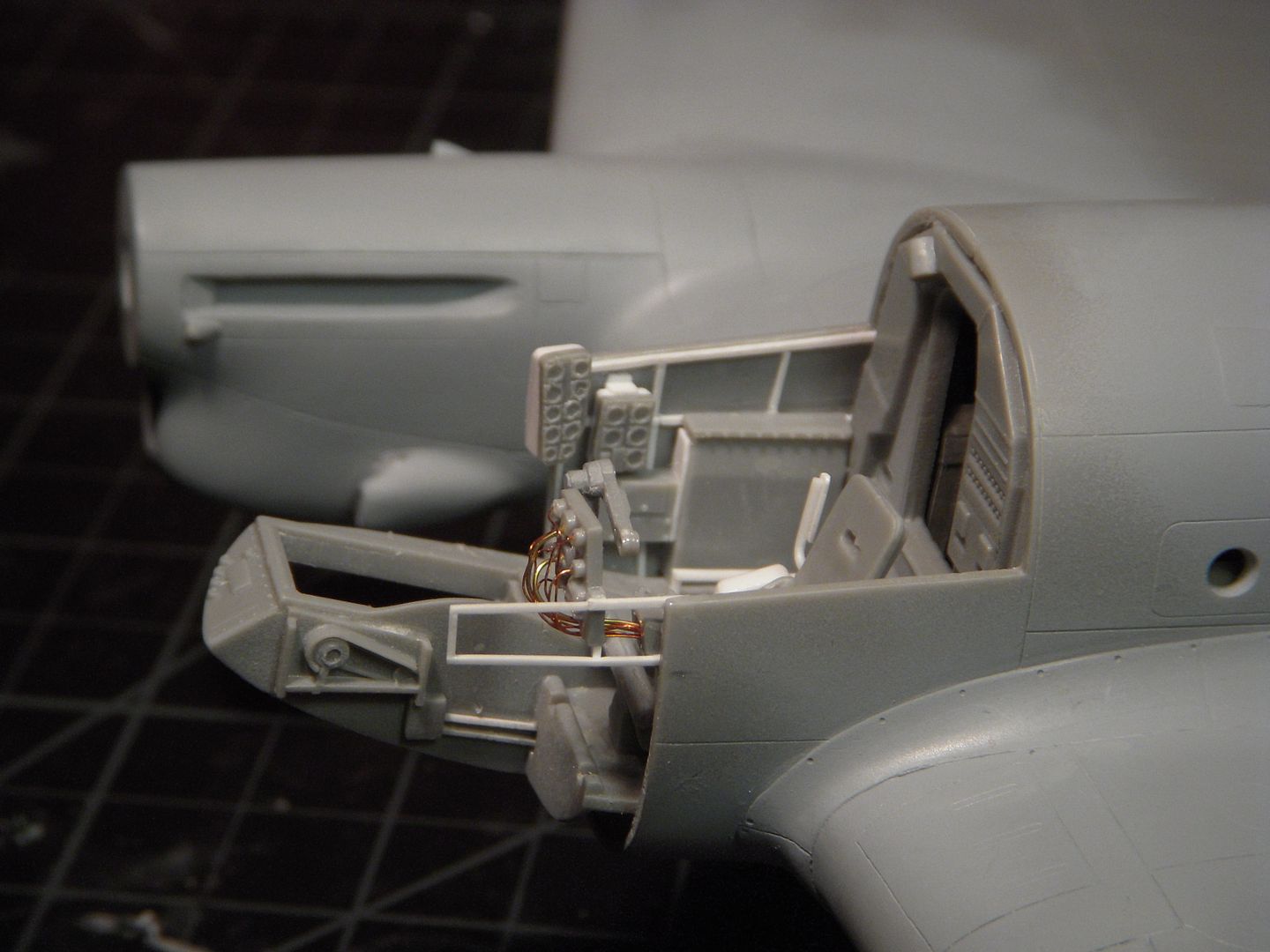

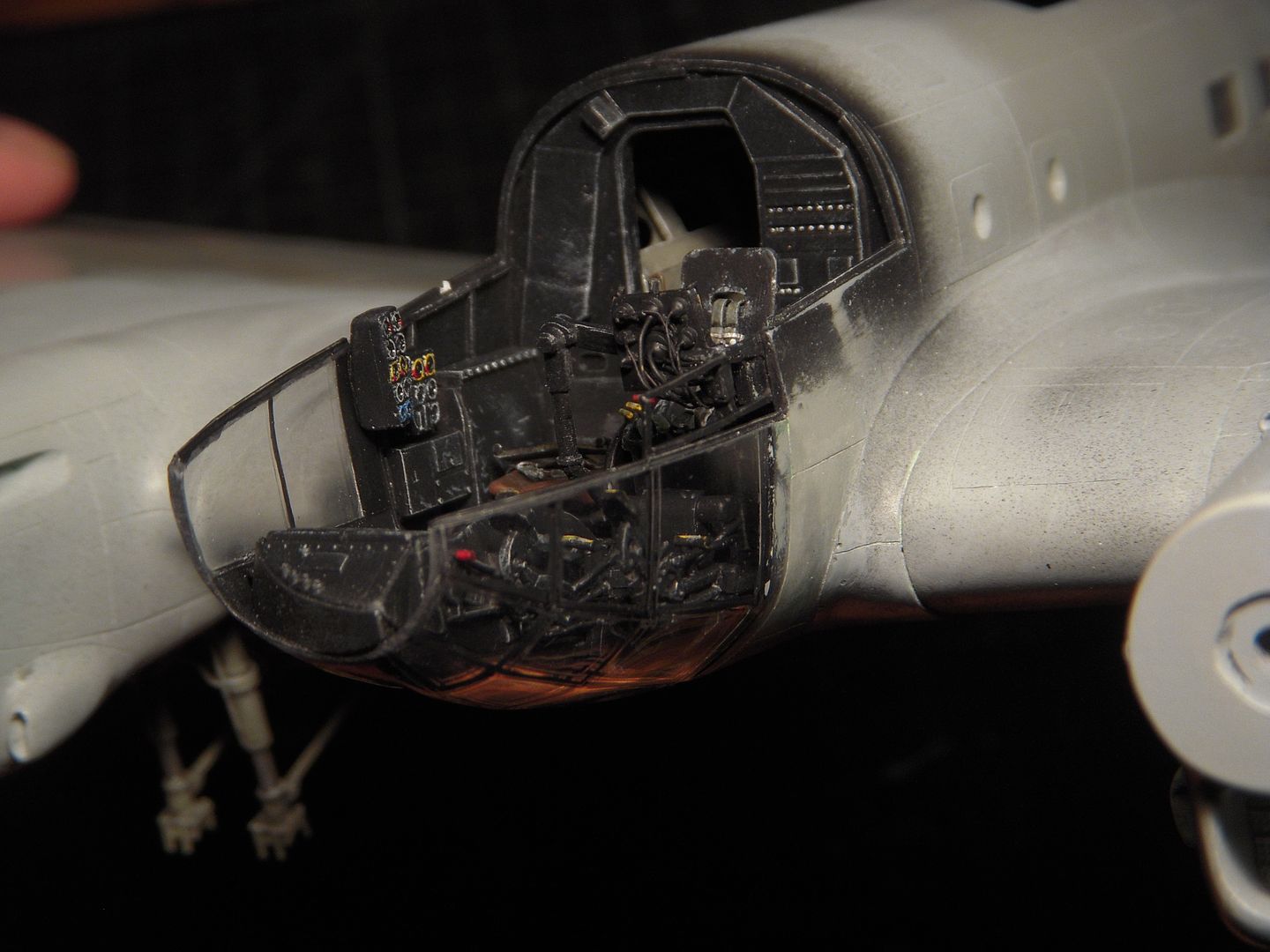

Got some of the interior bits made.

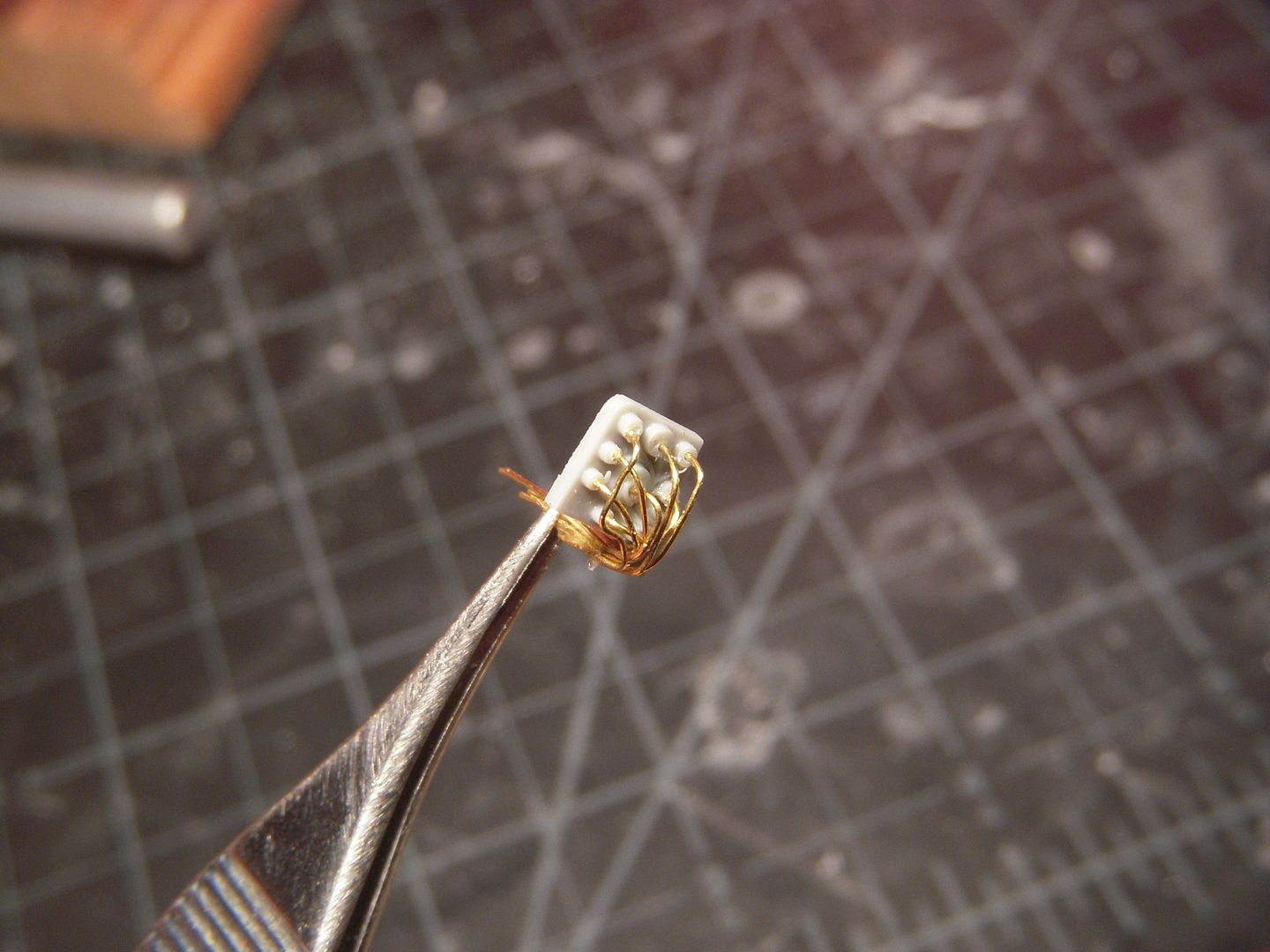

The back of the instrument panel mounted in front of the the yoke is very visible so the instrument hook ups and wiring was simulated by a few bits of wire.

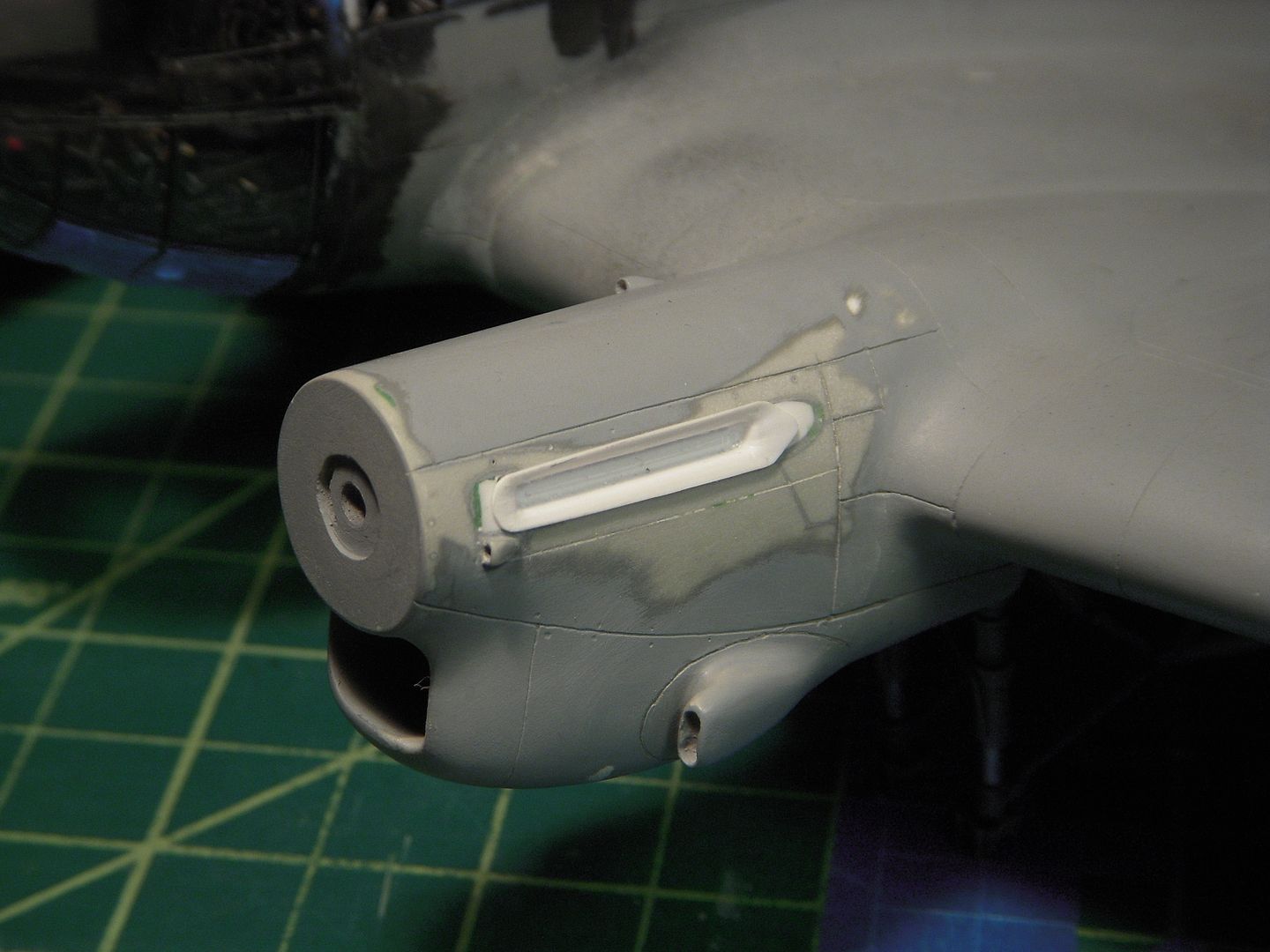

The prominent air-intakes where epoxied on and faired with much shaping and sanding.

A template was made to scribe the curved access panel.

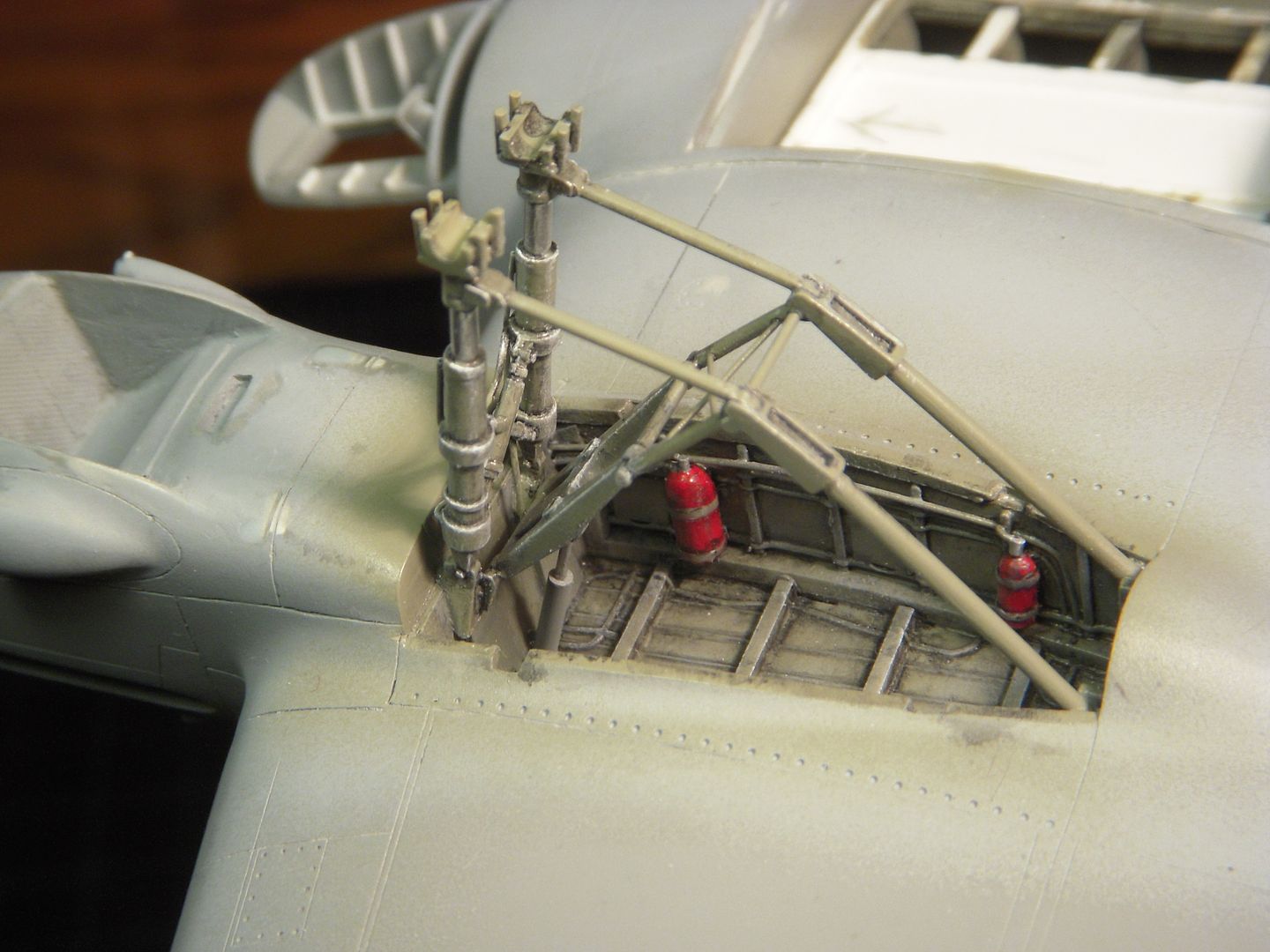

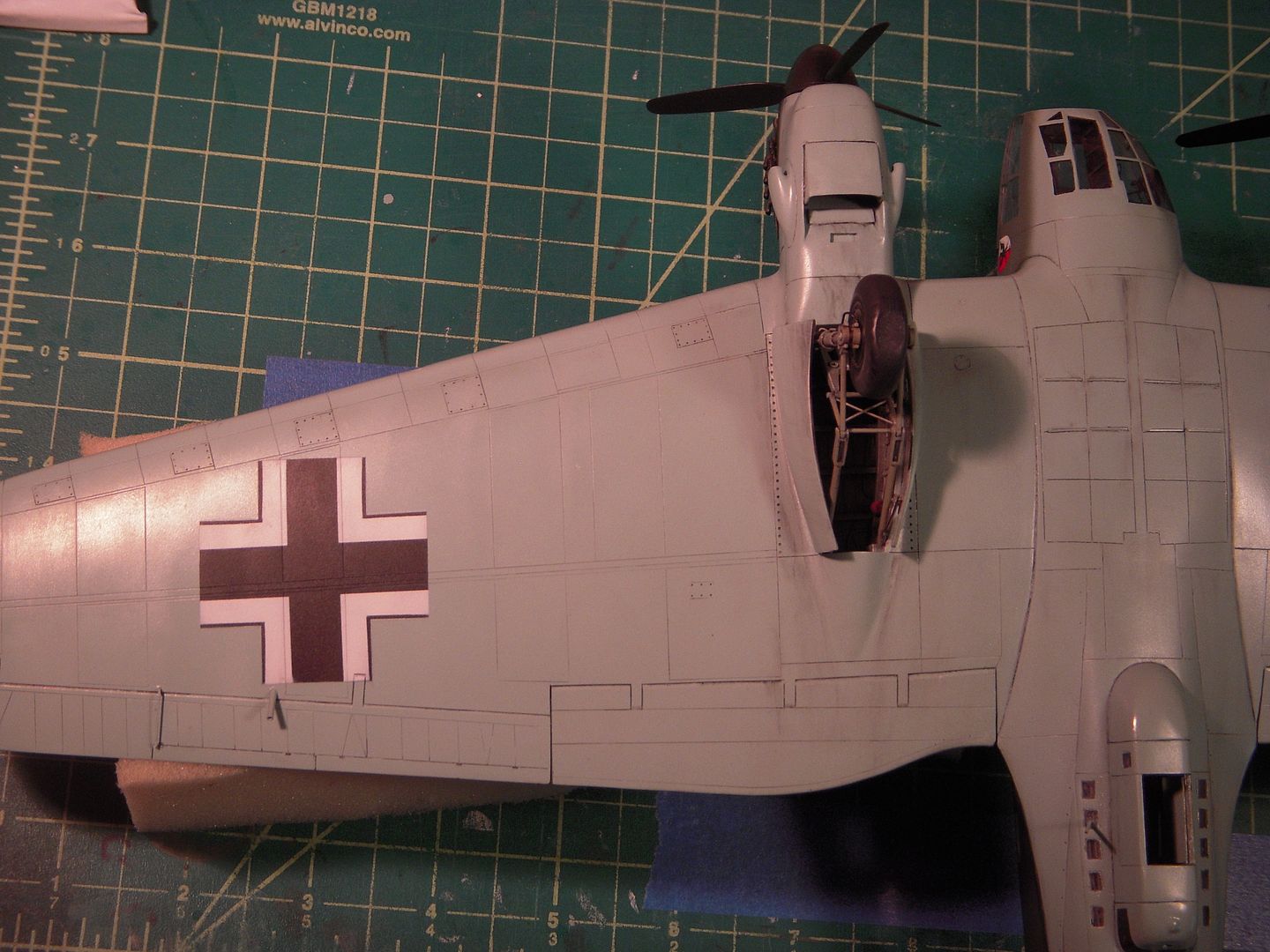

A bit more progress has been made. Both CASAs have the landing gear installed and detailed. It always amazes me how effective a wash and dry-brushed highlights are at making our models look real.

The struts installed and weathered. The retraction cylinder was fabricated from small aluminum tube and styrene rod.

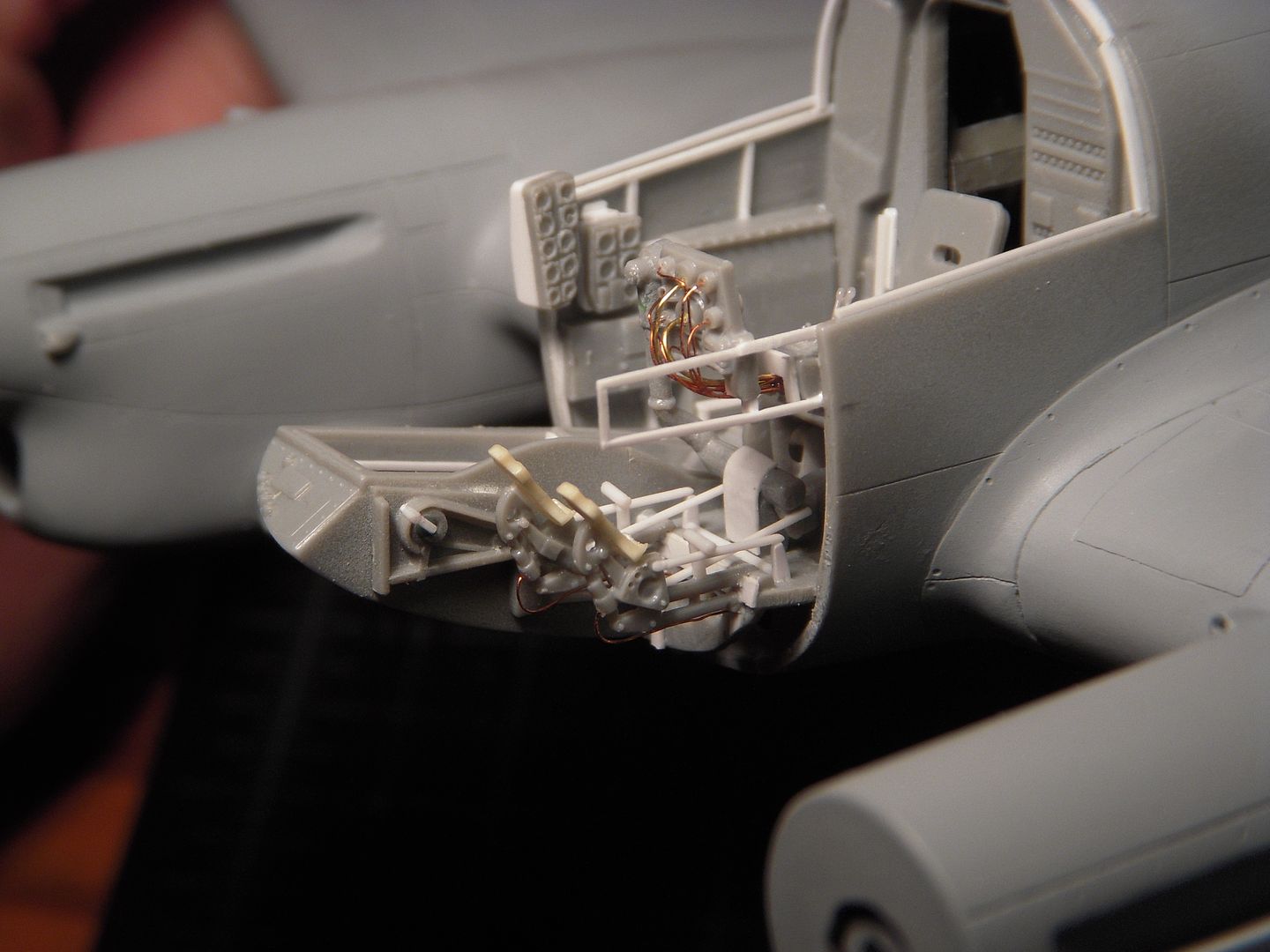

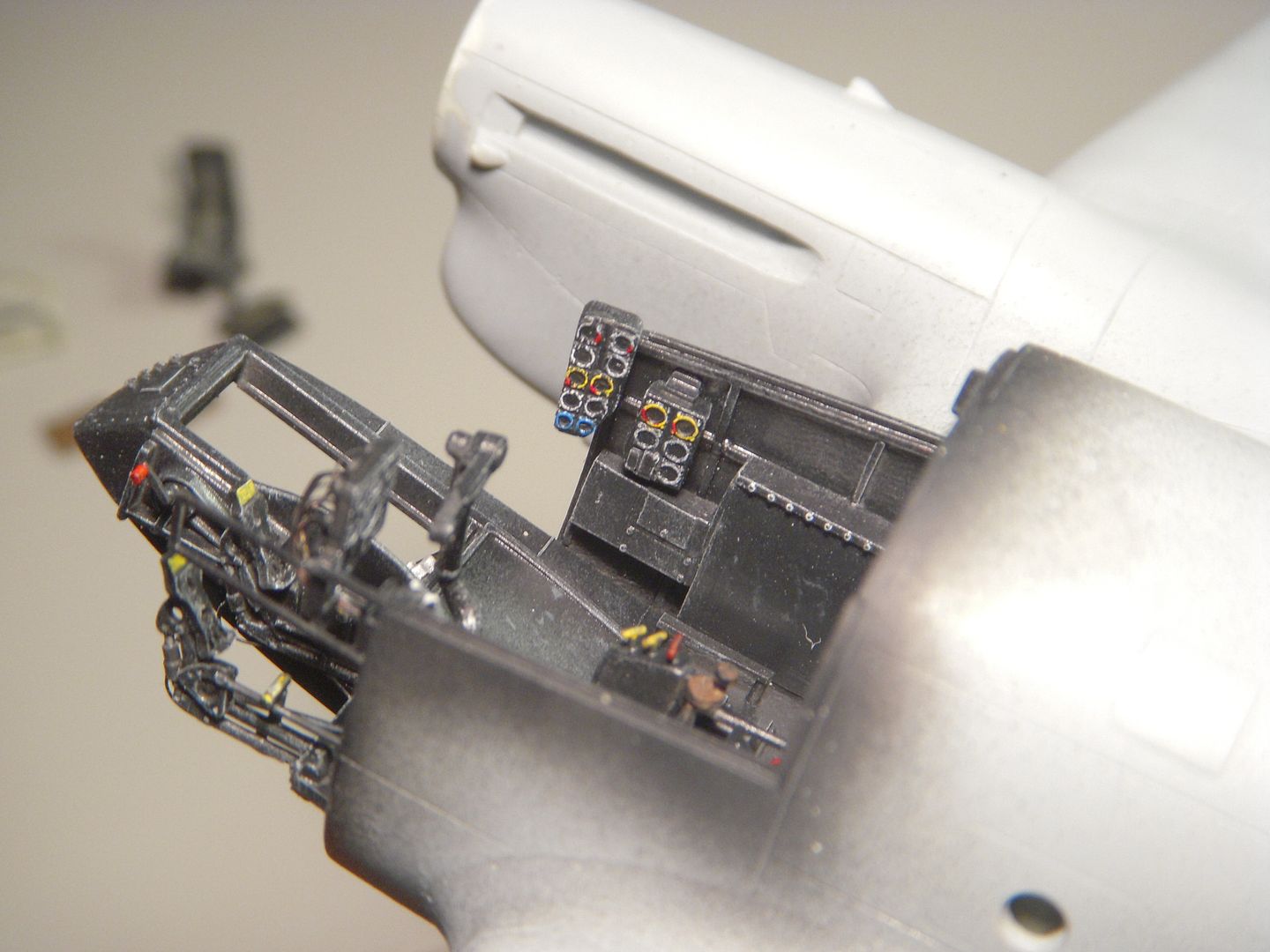

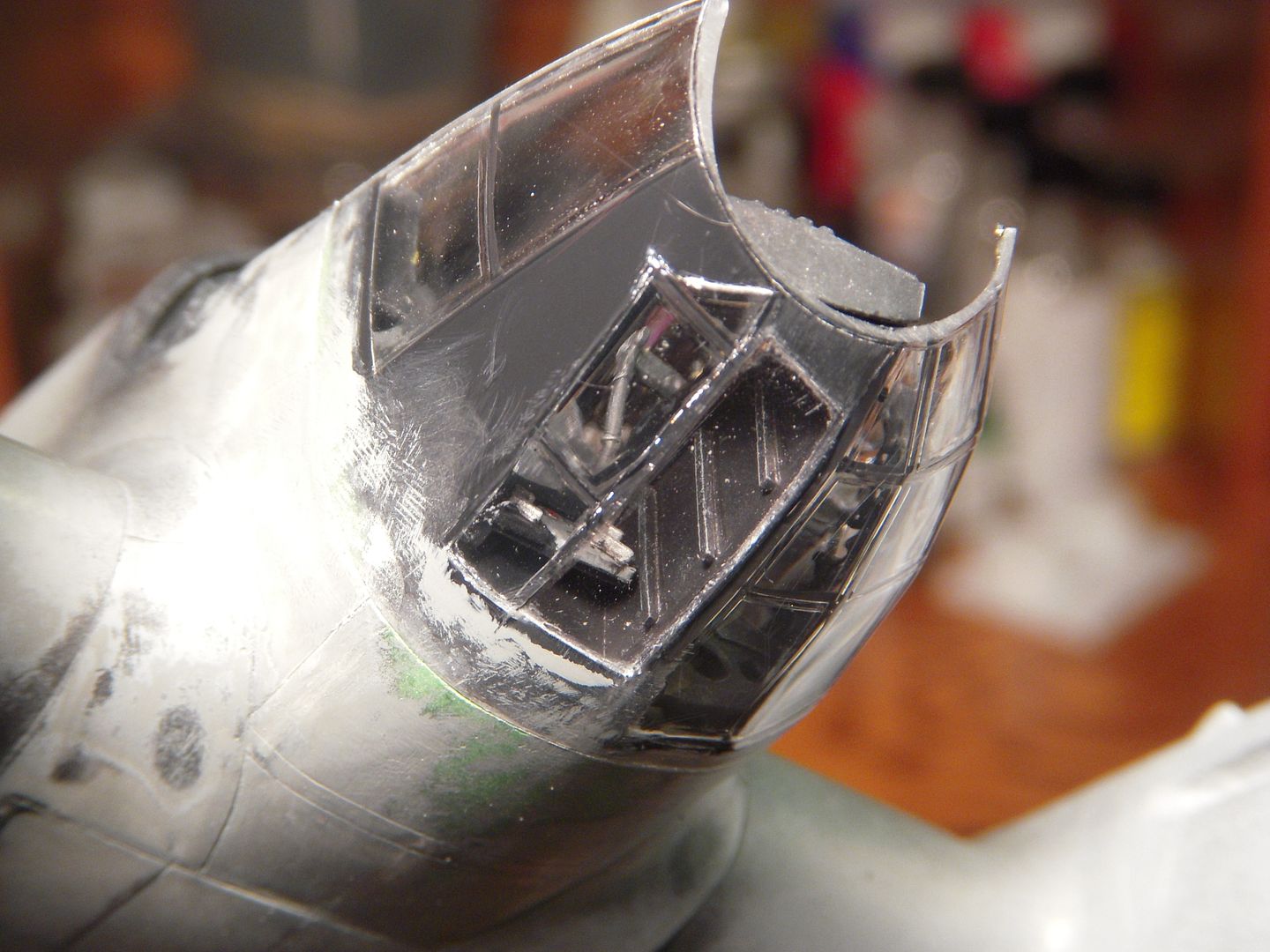

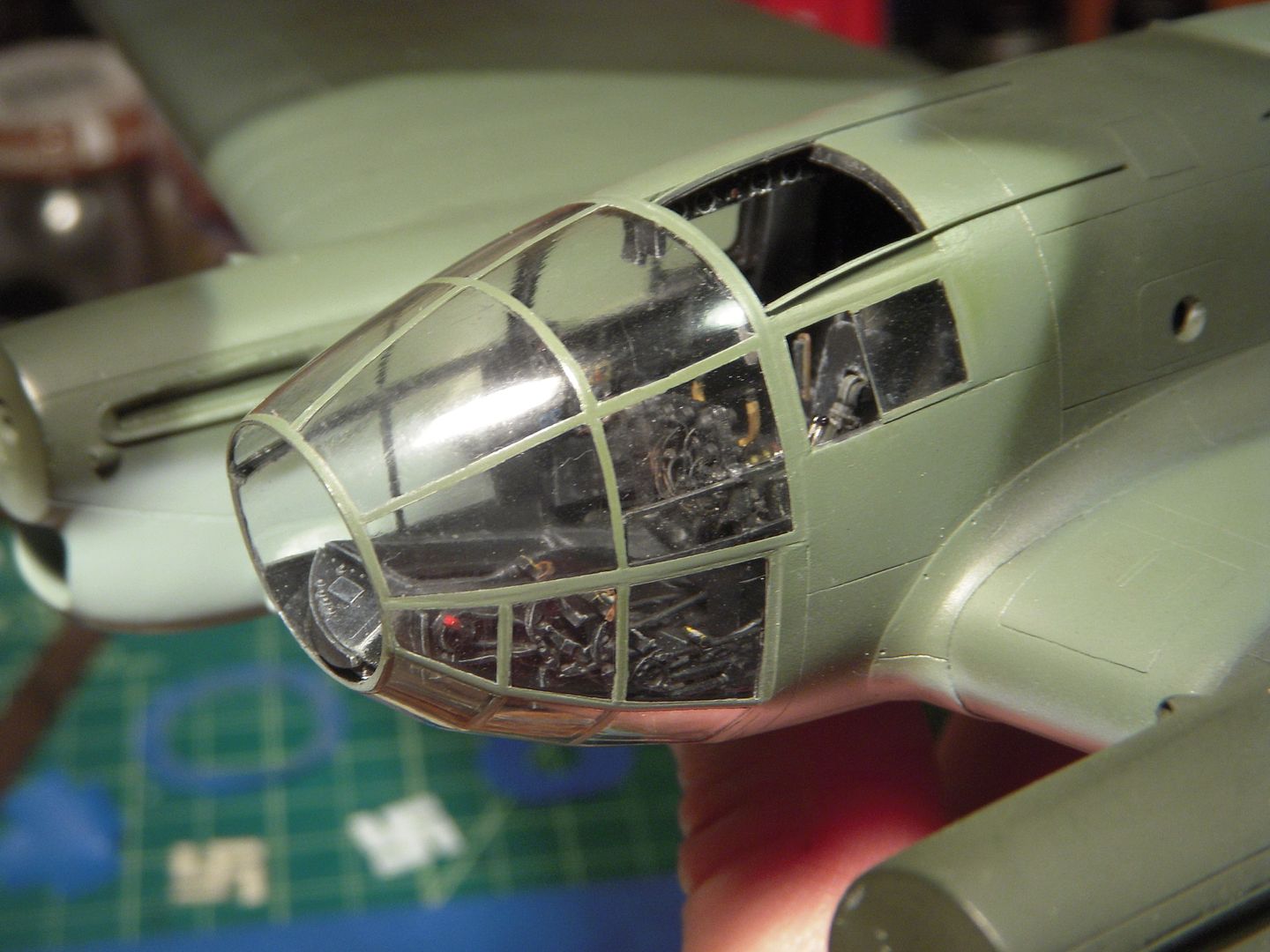

On to the cockpit. Most of the main detailing is done. To begin, the CASAs had a different instrument layout from the Heinkels, the distinctive overhead instrument panel was replaced by a number of smaller panels were scattered about the cockpit! I started by cutting the main panel from the kit into sections with instrument placements that replicated the new panels. The new panels were attached to their new location, the one in front of the control yoke the most difficult (and delicate) due to its use of canopy framing for attach points. This is going to prove interesting not to knock off until I get the canopy installed!

To avoid visibility issues at night or bad weather caused by distracting reflections on the extensive cockpit glazing, the pilot's seat could be raised so the pilot could look through a hatch in the top of the canopy. Some styrene rod was used to replicate the complex mechanism at the rear of the cockpit that allowed the seat and controls to be raised together.

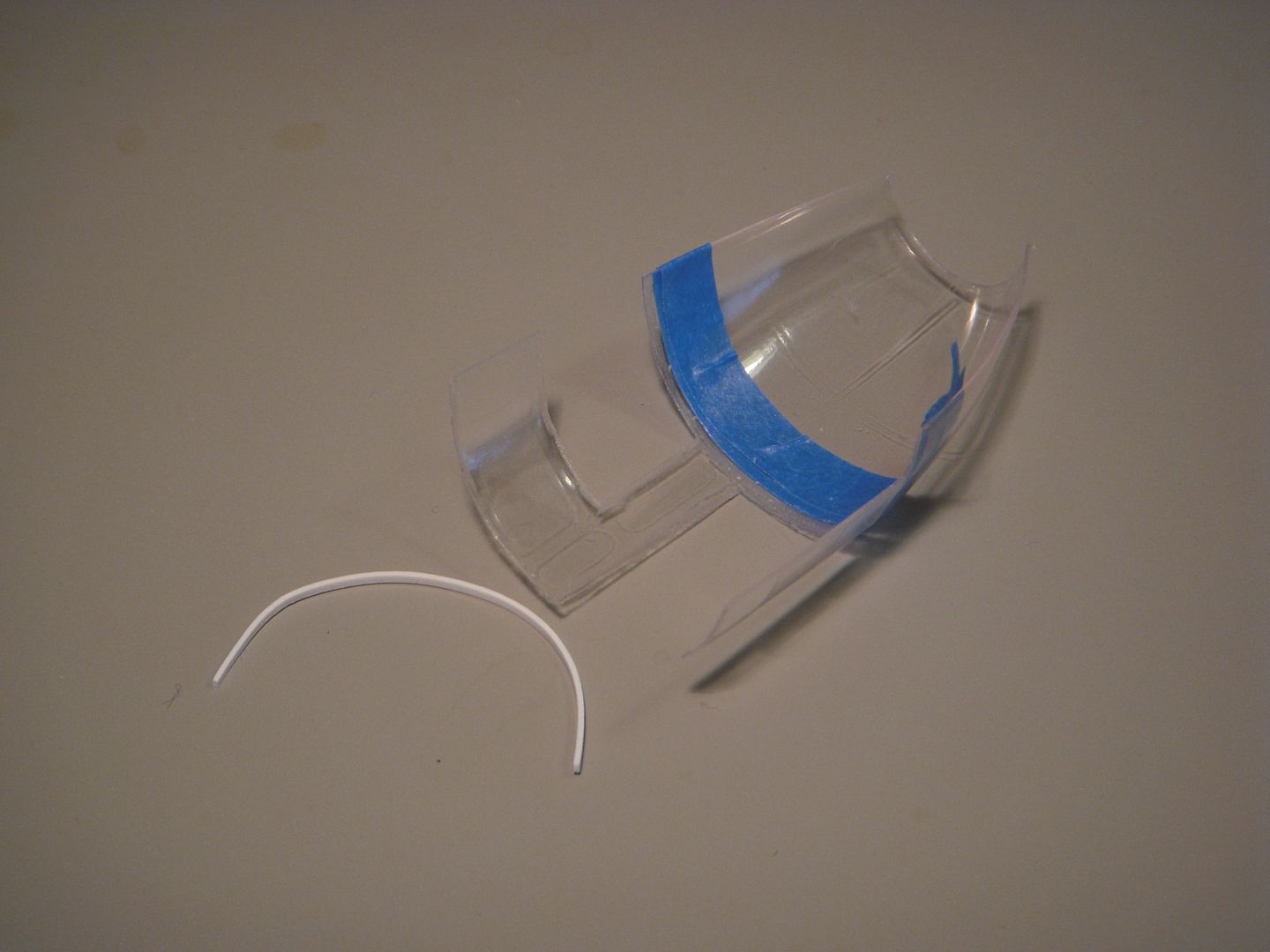

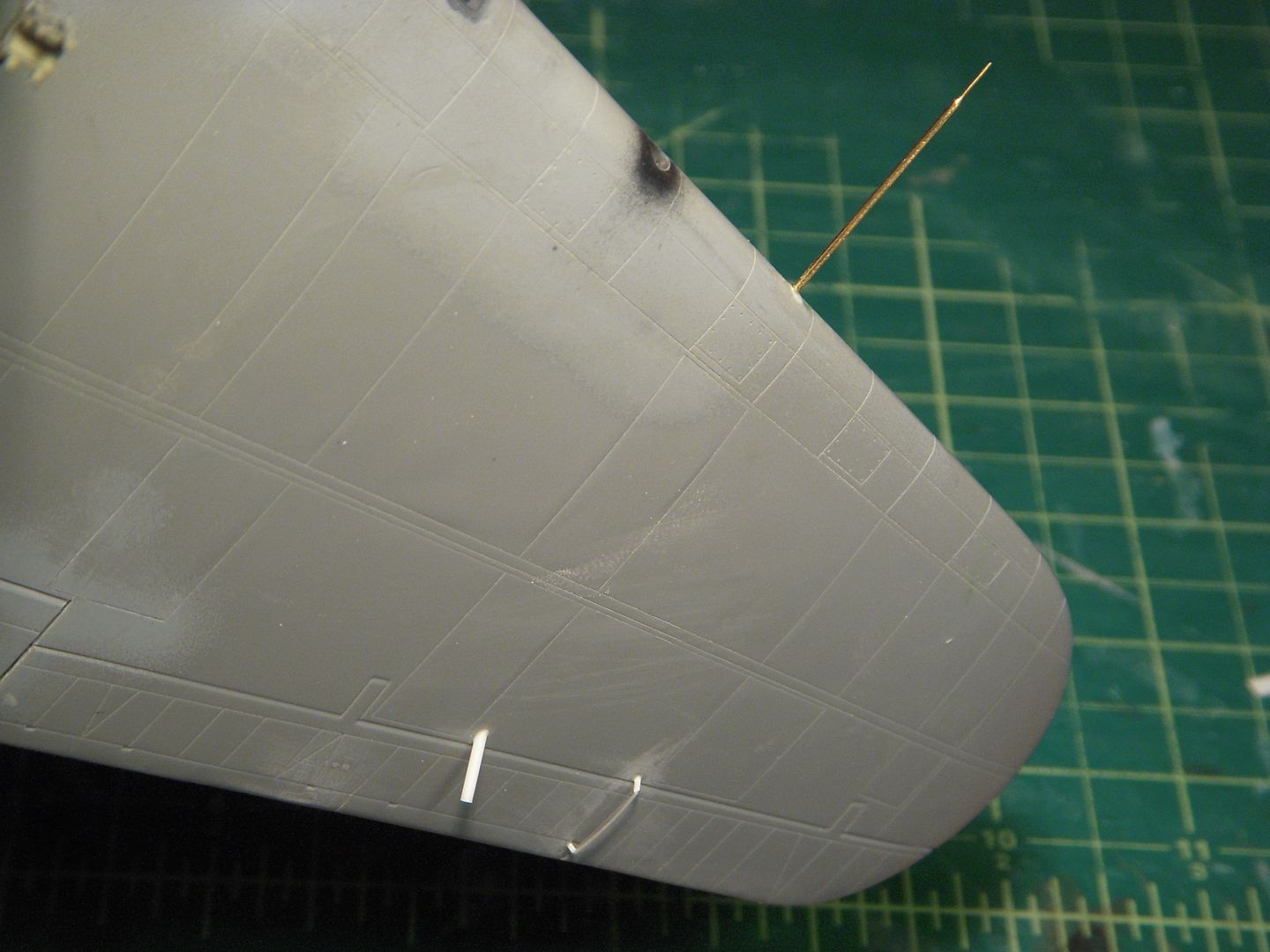

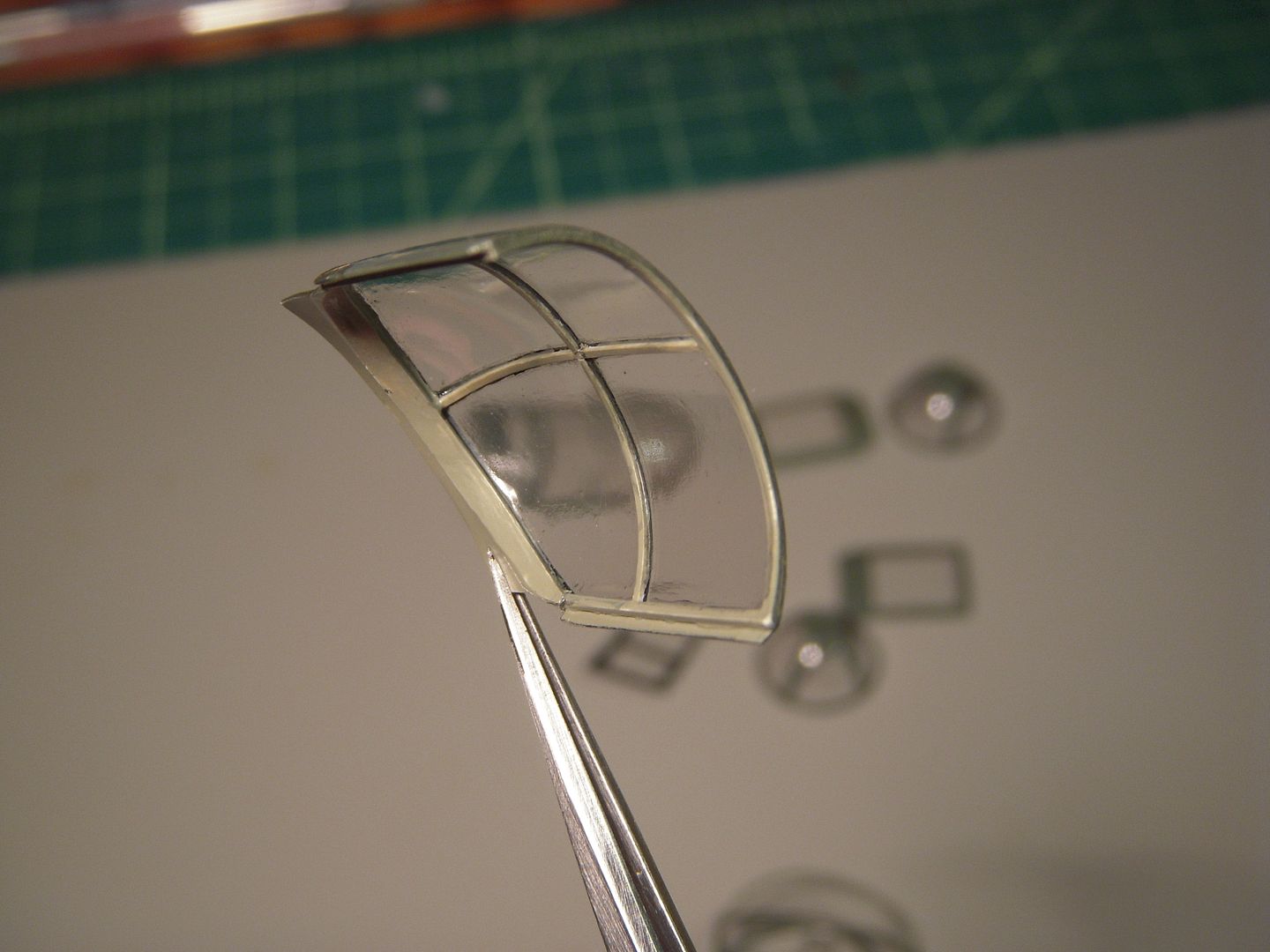

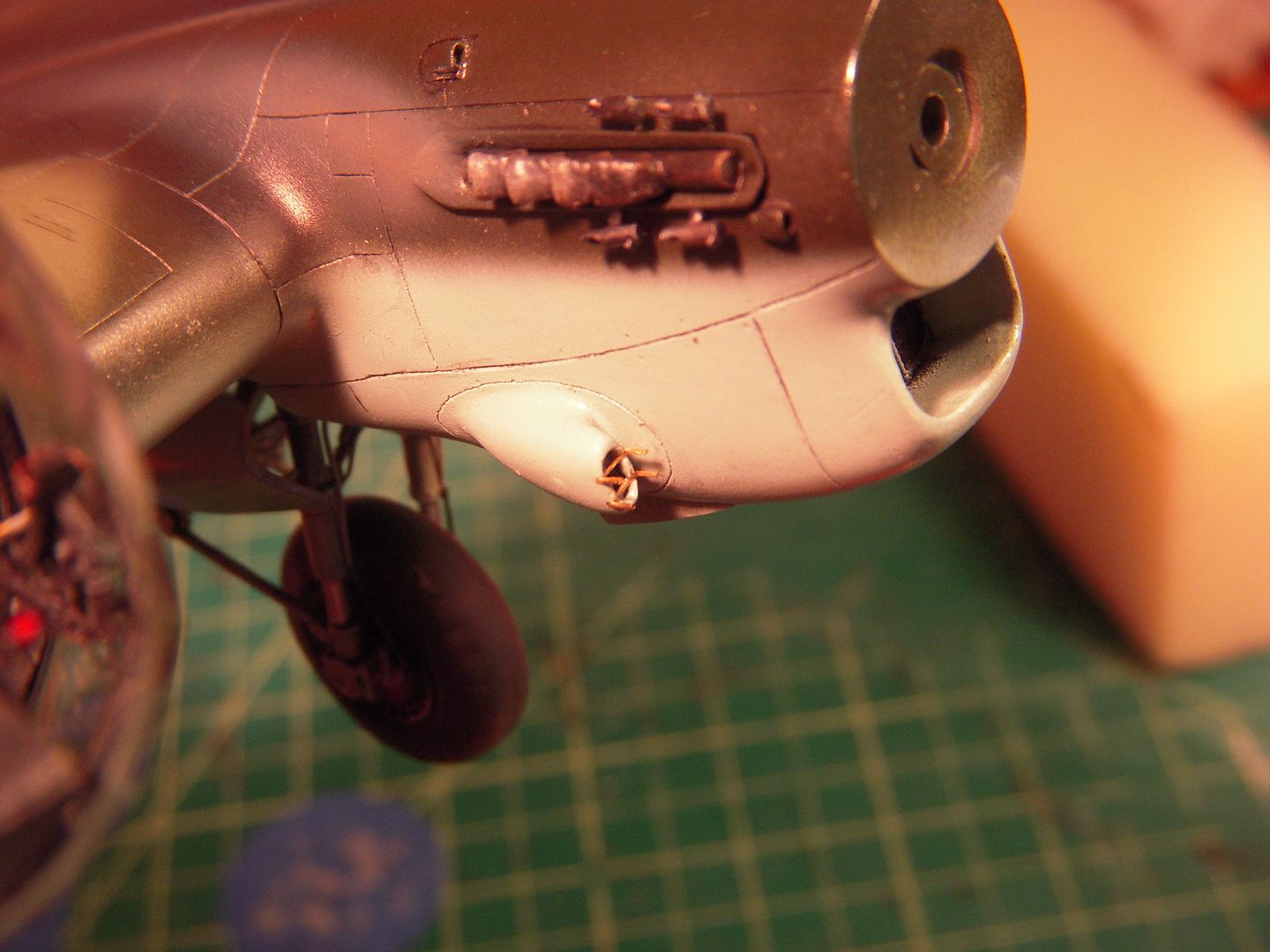

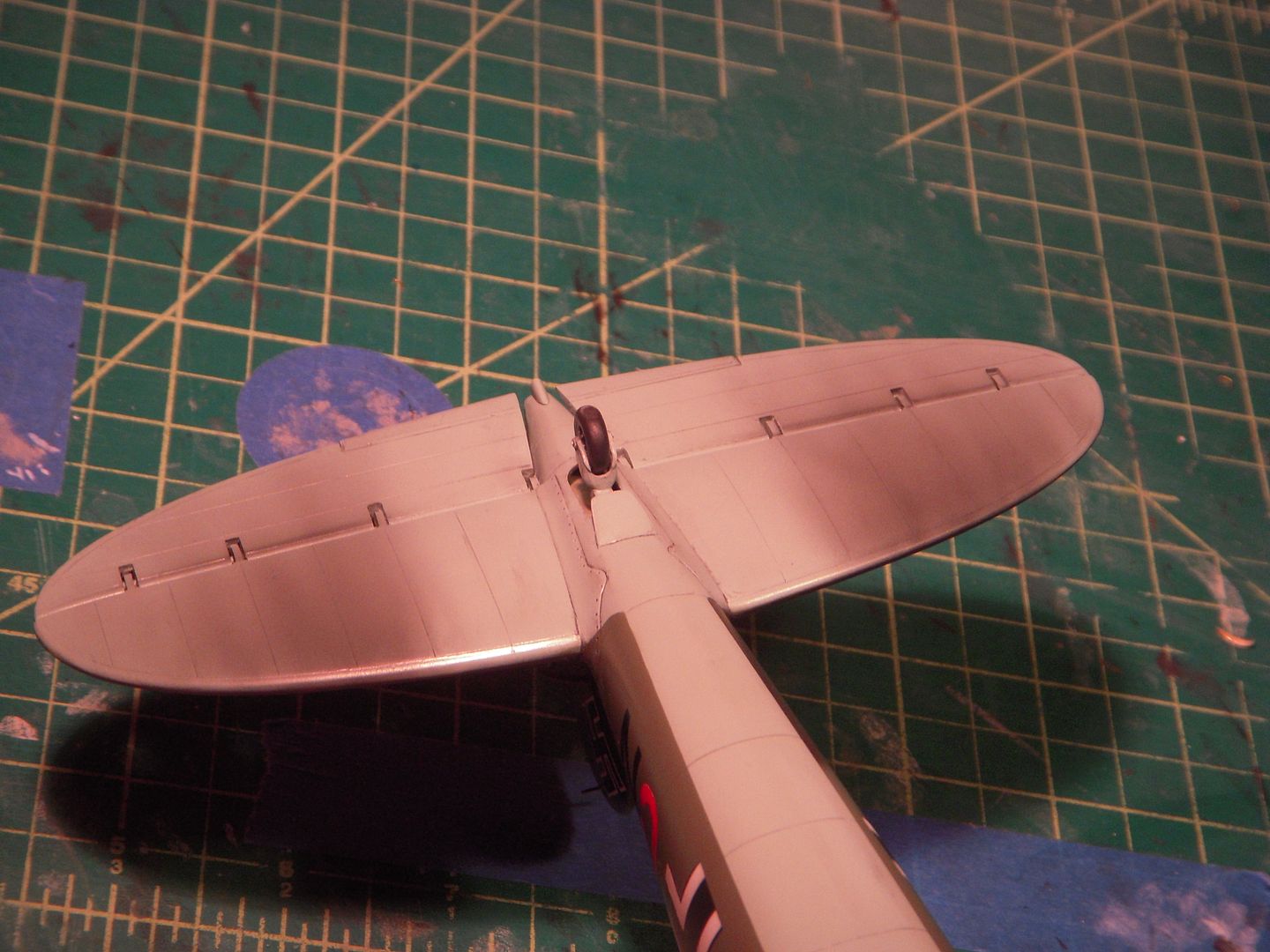

Landing lights were fabricated from disks punched from foil from the top of a wine bottle, cupped by pressing with the rounded end of a paint brush handle. As you can see it took me a couple of tries to get two good ones! A bulb was made from clear sprue and the cover heat formed over the leading edge of the wing and cut to shape.

Thanks for looking, hope y'all enjoy the in-progress reports.

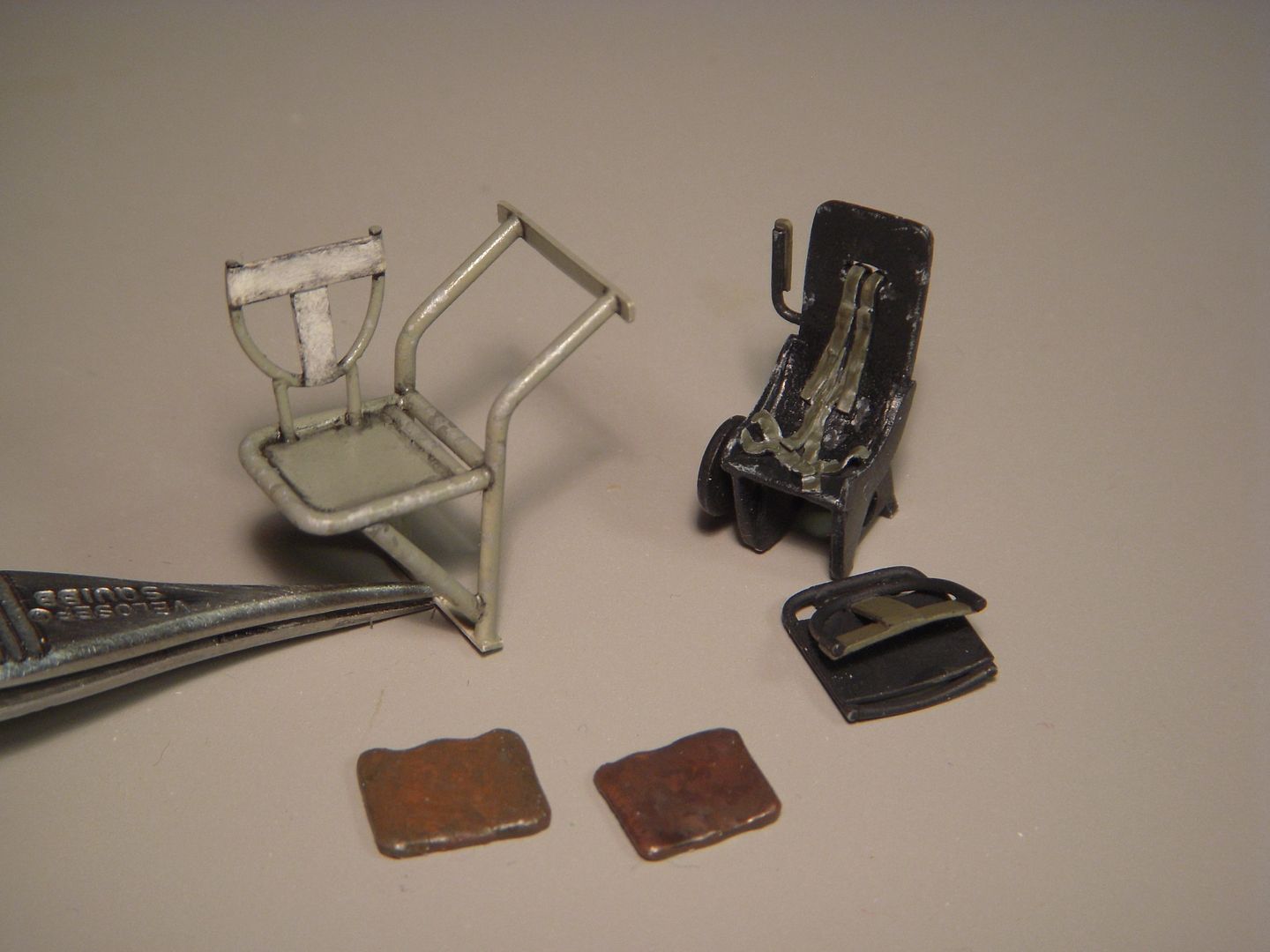

I think enough fiddly bits have been added to the cockpits to consider them ready for paint. :yahoo: The distinctive tall throttle levers were added from stretched sprue, rudder pedal mounts built up from styrene rod. The rudder pedals themselves pirated from a Me-109 detail set. Aileron, rudder trim cranks and a few more rods to represent the seat raising mechanism finish the detailing behind the seat. The pilot's seat will have to be attached after the final painting. The next trick will be to keep from breaking off any of the exposed details before I can get the canopies fitted!

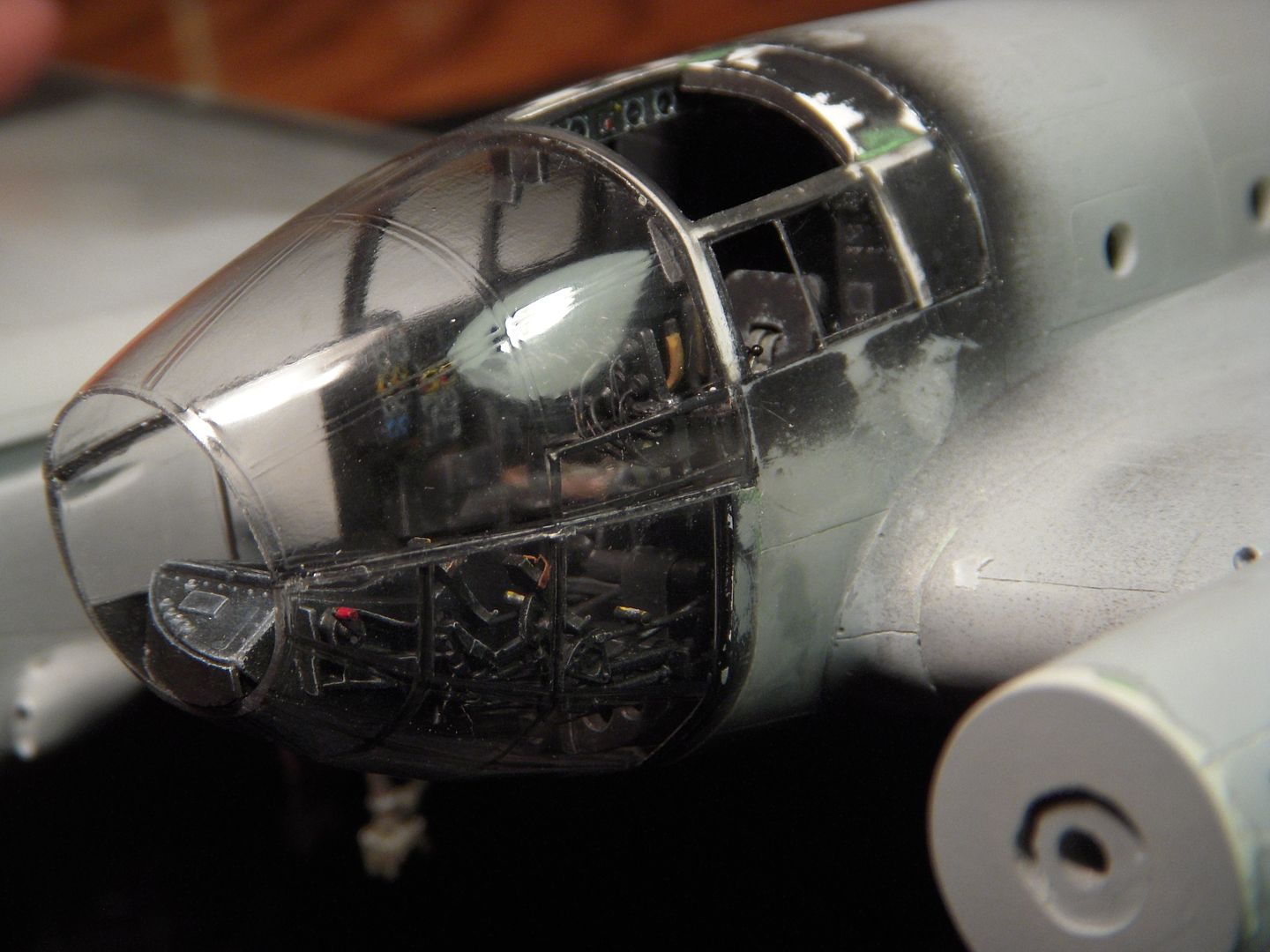

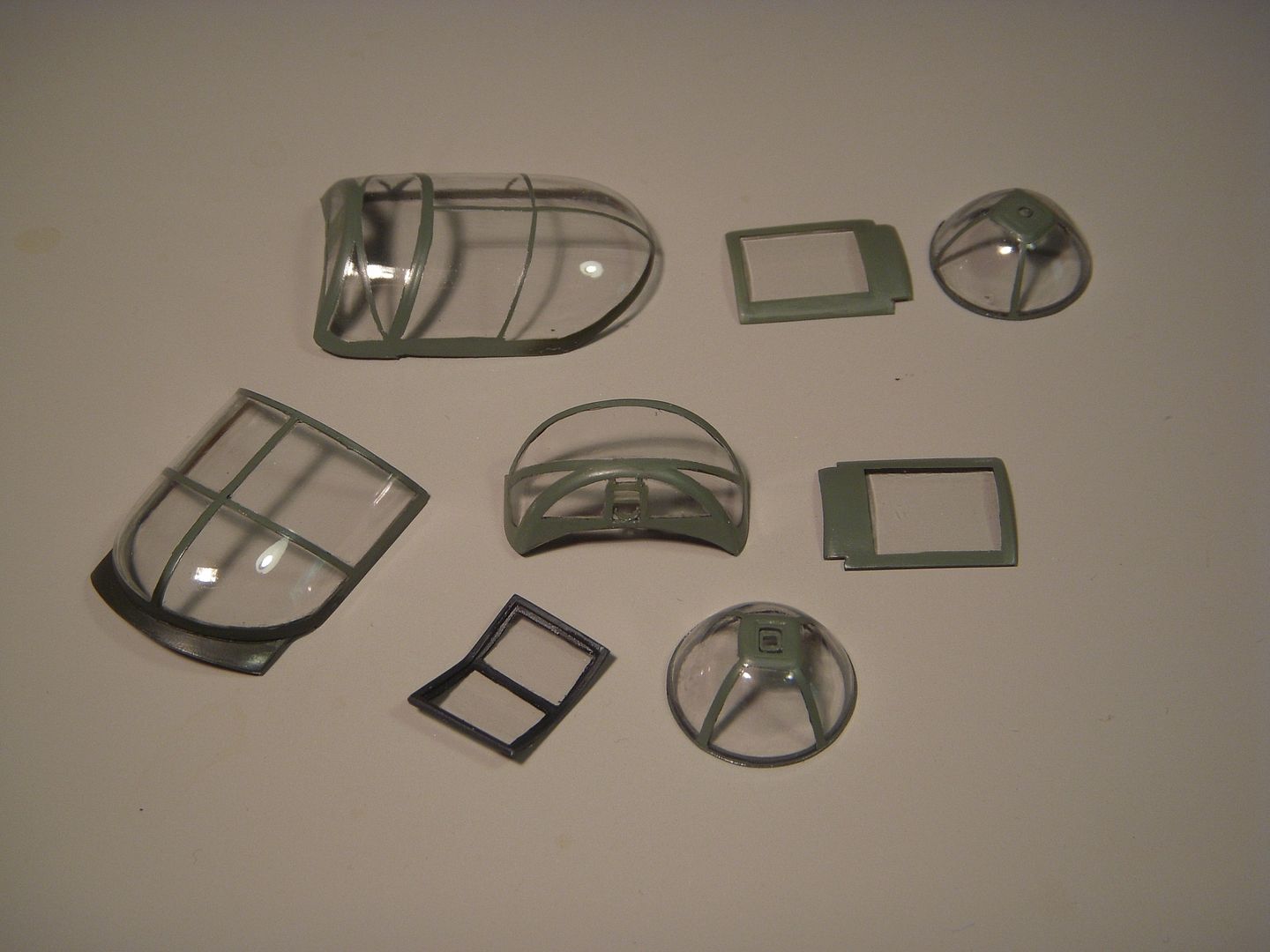

A lot of checking and trimming will be required to fit the large canopies. After all that work on the cockpits I intend on opening as many hatches and windows I can in the nose!

[ihttp://i1115.photobucket.com/albums/k550/modelpicposter/CASA%202%20111/DSCN6288.jpg[/img]mg]

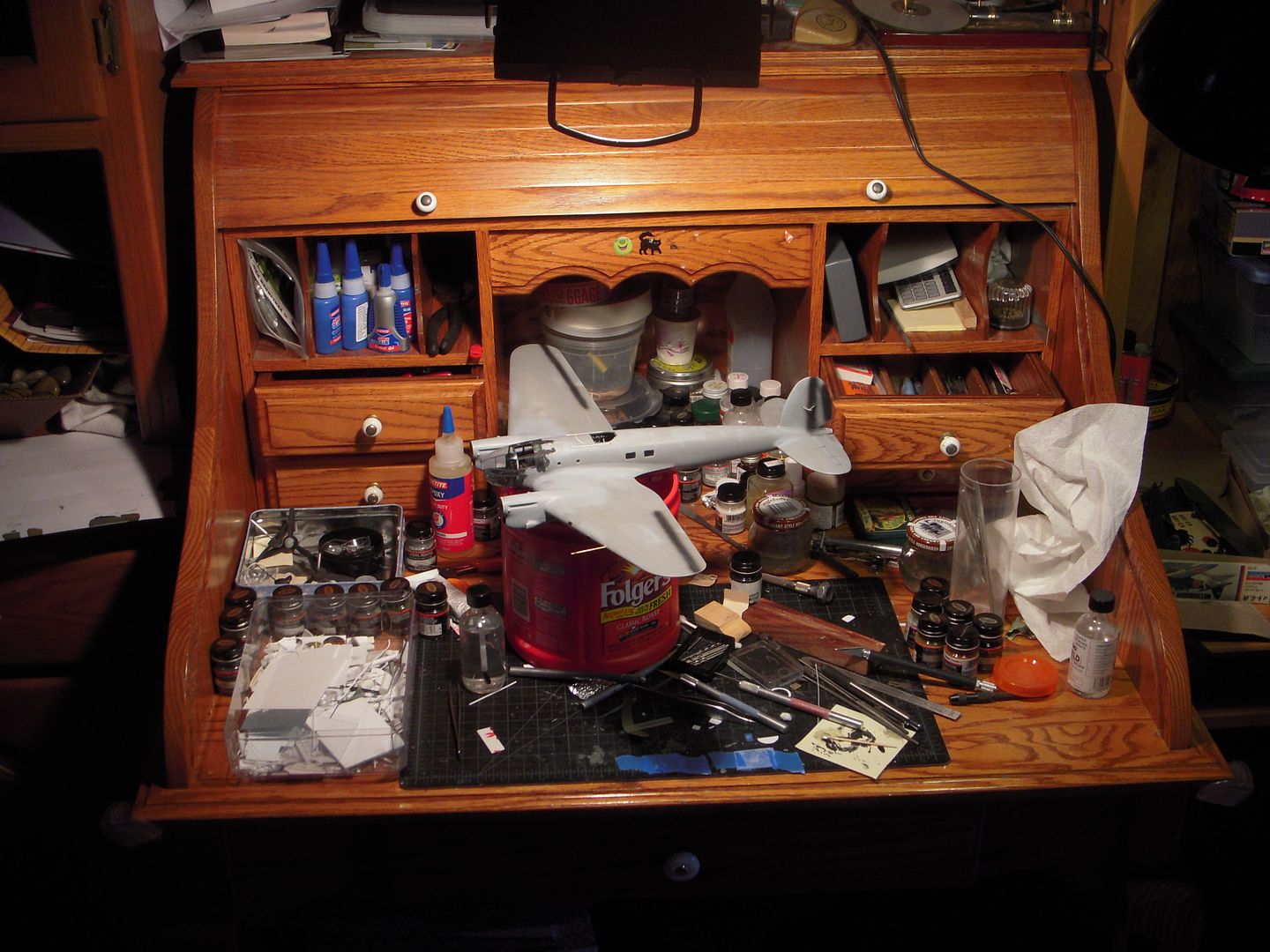

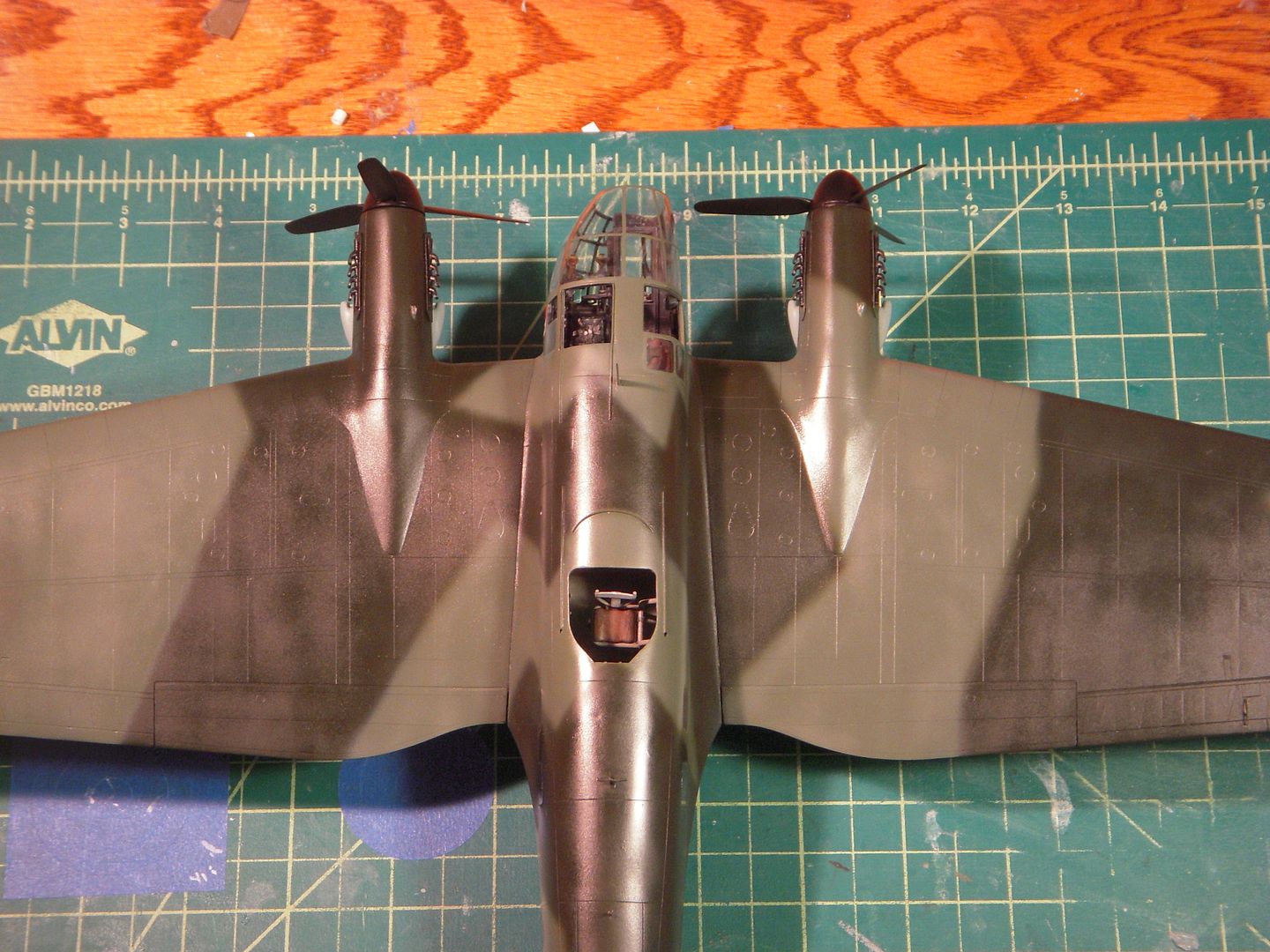

The CASAs are large models and take up quite a bit of space on the work desk!

Thank you to those who are still following my glacially slow building pace, I hope I am able to reward your patience!

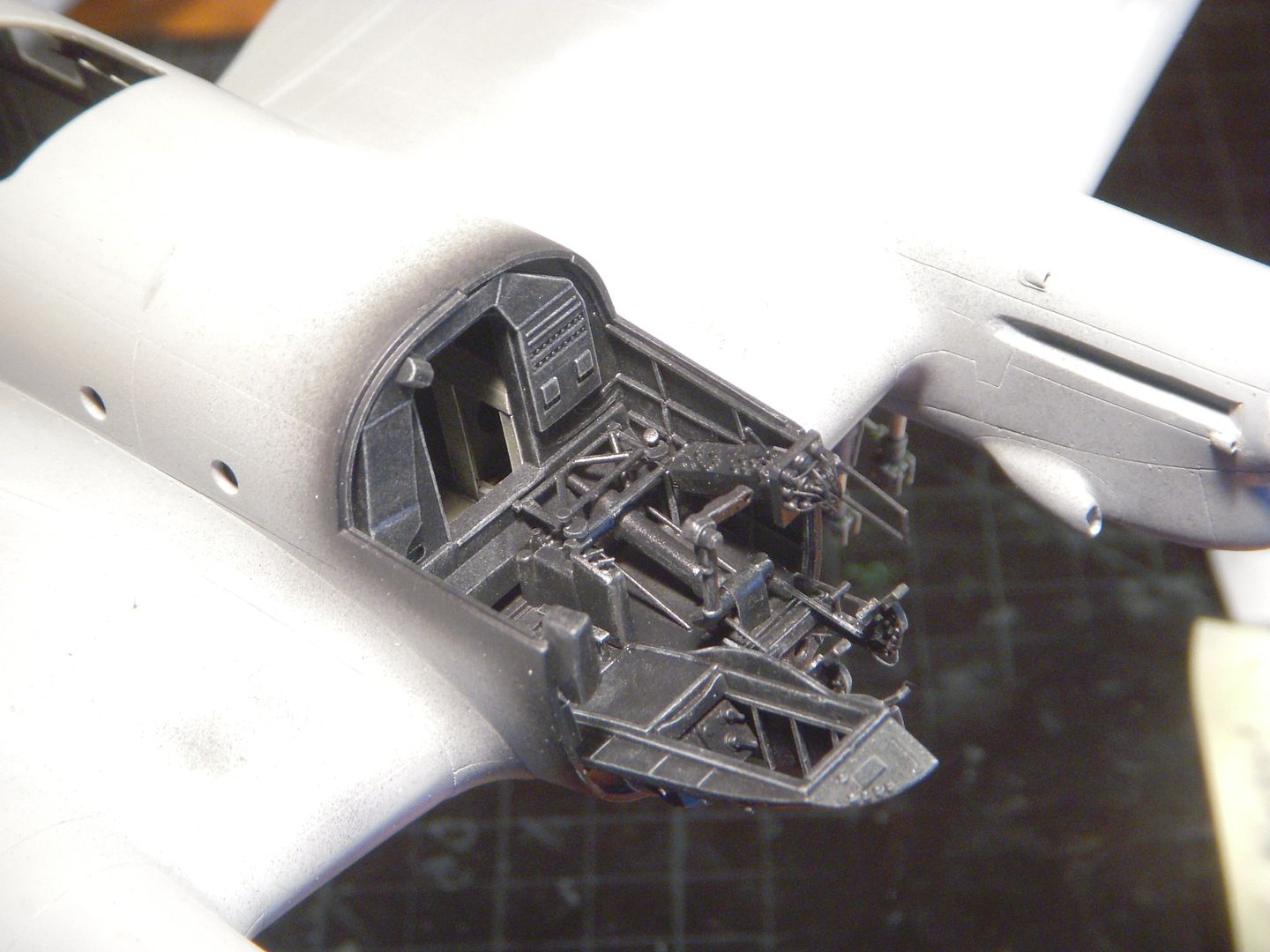

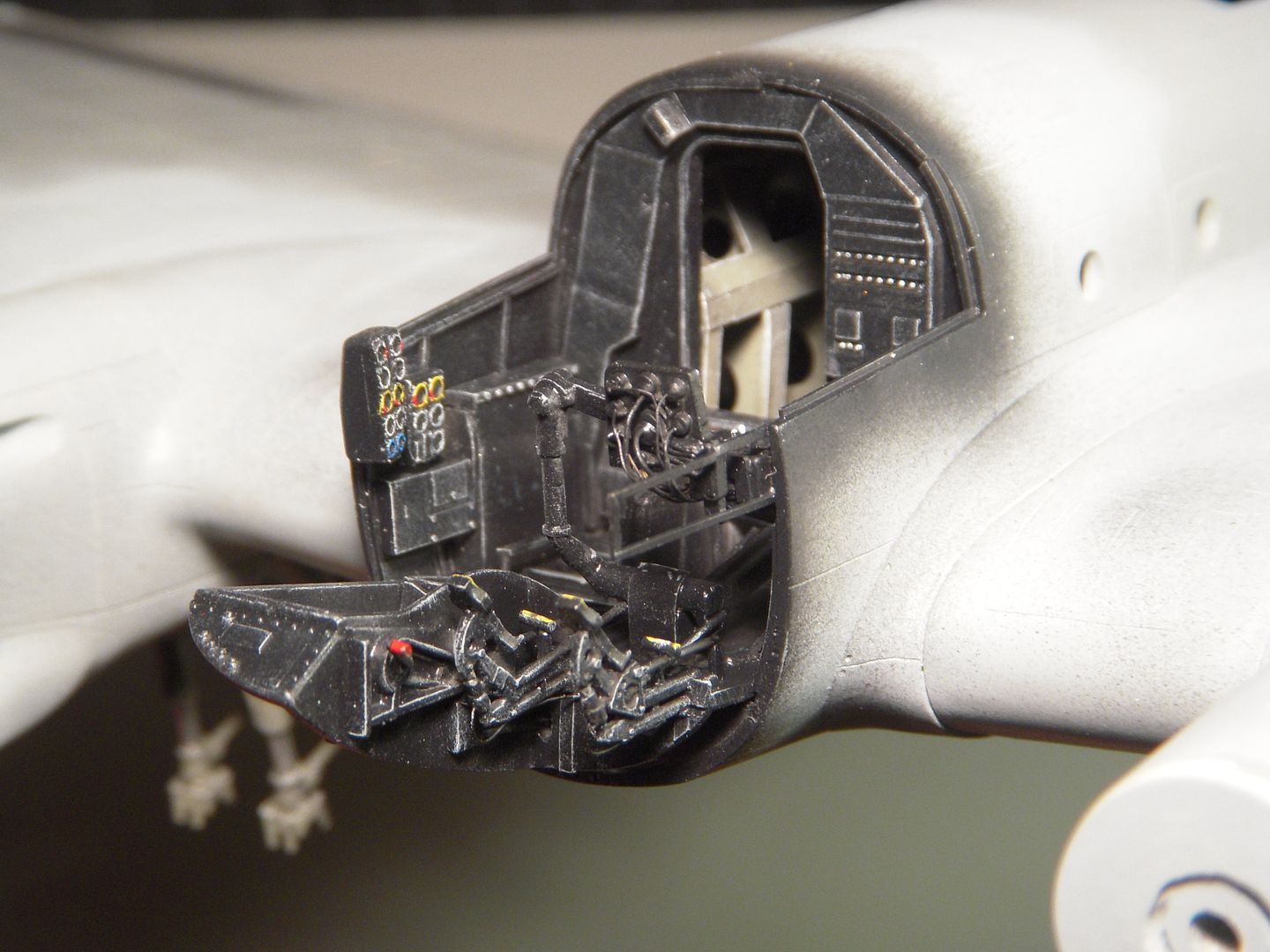

Just enough time for a quick update. Painting has started on the cockpits, base coat and some weathering applied. The colors may seem dark compared to what one may expect, but from what I have seen in my research the CASAs had an almost black finish to the cockpitsrather than the RLM grey of Heinkel built aircraft. Black was in vogue for cockpits in the 1950s into the early 1960s about the time these aircraft were in active service with the Spanish air force. Initially painting the canvas bombardier seat and seat belts a worn canvas color, I found the contrast much too stark. Combining a bit of artistic license with plausible period replacement of the canvas material, I reduced the contrast and reinforced the idea of an active military aircraft in the 1960s by repainting the light canvas parts with a green drab hue.

Hopefully I can get the rest of the cockpit detailing completed this week and begin with the task of installing the vacuformed canopies, they look like they're going to be a challenge!

The basic dark grey

Start of the weathering and detail painting.

The engine instruments are quite colorful with the color coded operating limits. Needles and glass yet to be applied with paint and clearcoat.

Some of the smaller bits almost ready for installation.

Happy New Year to all! Some progress was made over the holidays, the interior is just about ready for close-up. A bit of weathering was applied as these aircraft were very late in their service lives at the time of the making of BoB and therefore would have a well used appearance. In the cockpit the pilot's seat was installed with belts and buckles made from heavy foil. On the ground, the bombardier/gunner's seat would normally be folded up against the right side to provide access to the cockpit, but I decided to install the scratch-built seat with the back folded, but in the down position as it adds a bit of interest and color.

The dorsal gunner's seat was equipped with foil belts and buckles, the belts left dangling from the frame rather than being neatly stowed for a bit of interest. I'm sure the crew chief will have something to say about that when he bangs his head on the metal buckles!

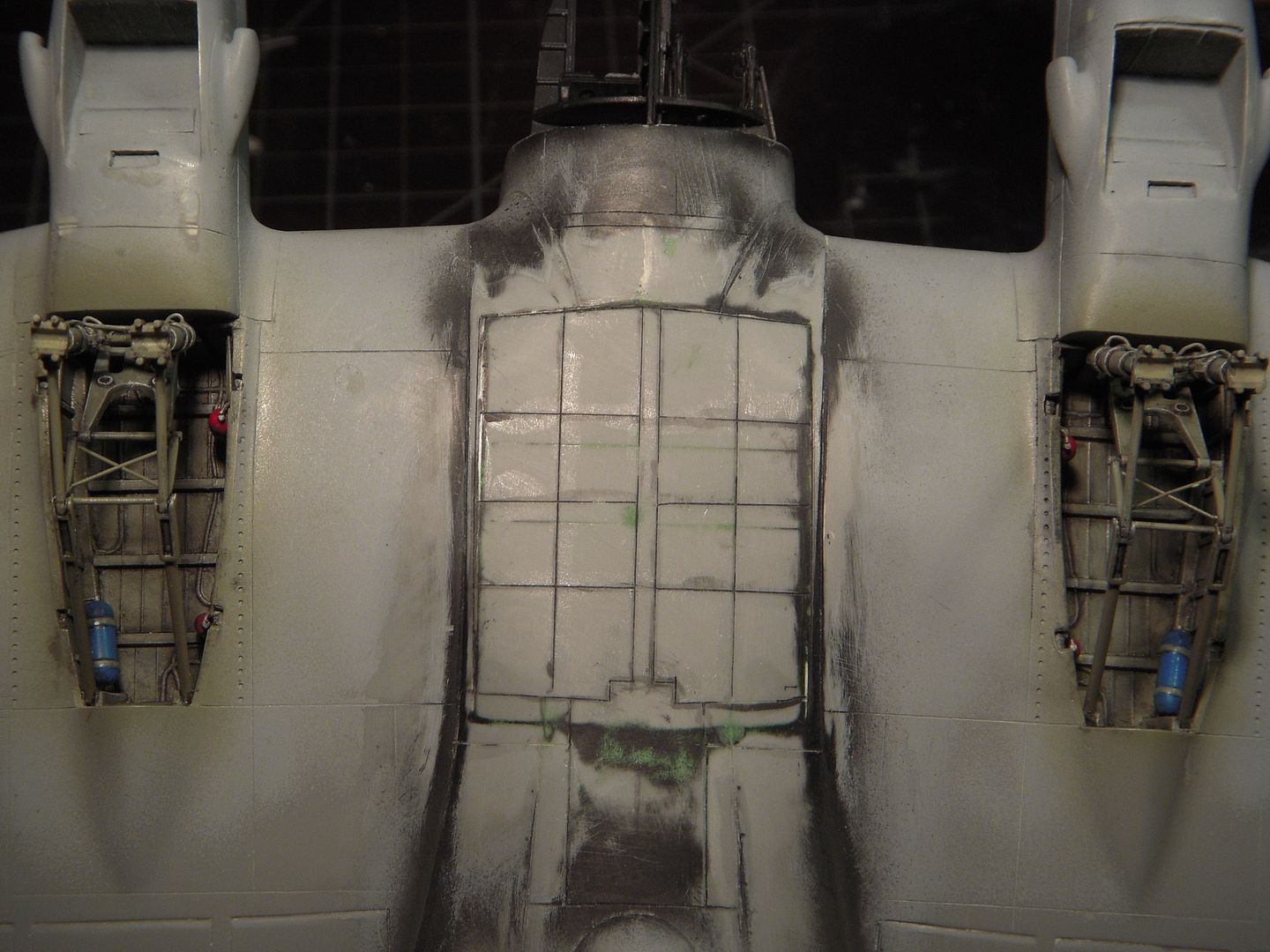

The bomb bay doors were not depicted correctly for the CASAs, so the lines were filled and rescribed. A bit of wash was run in to make them easier to see here.

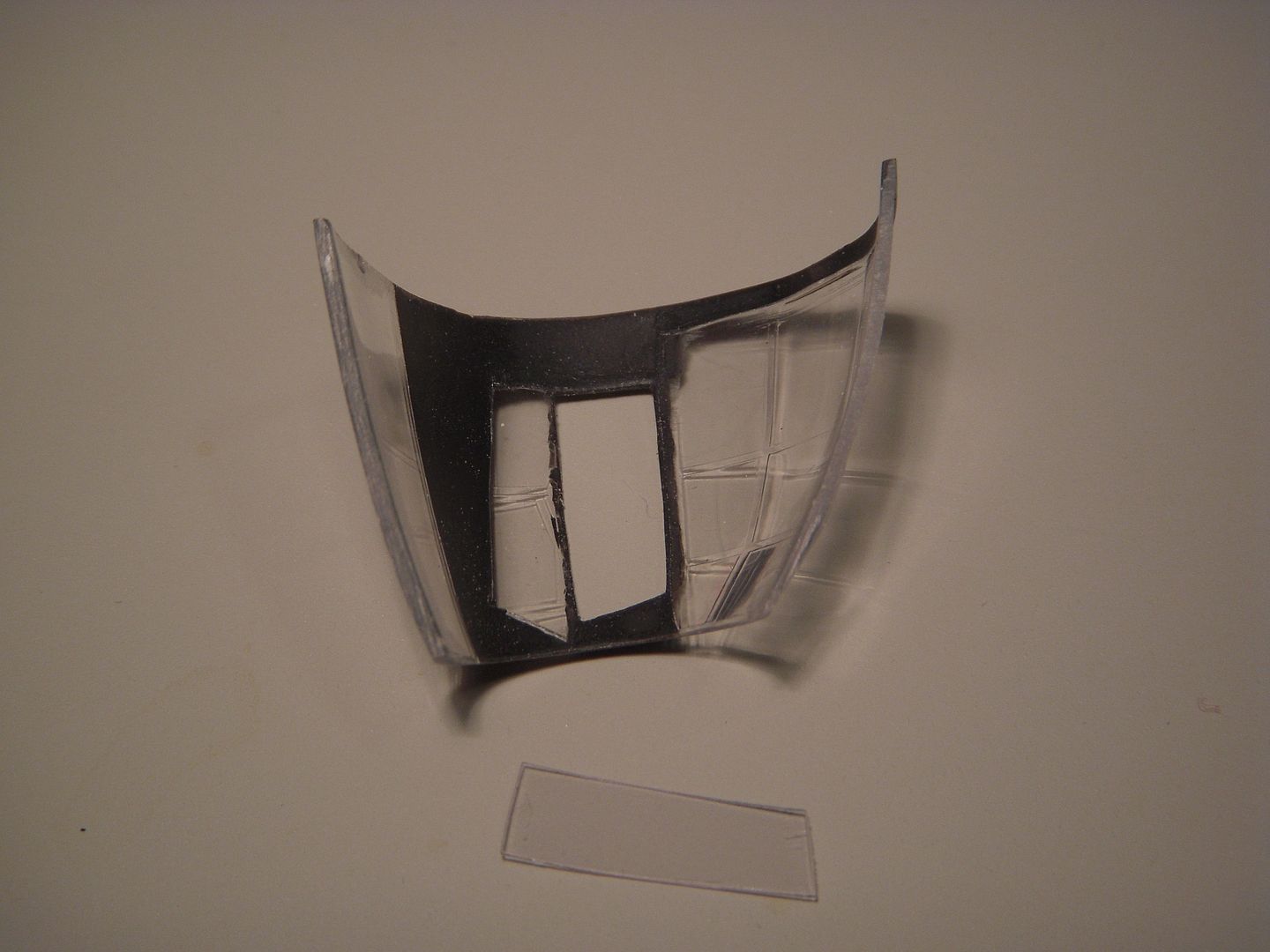

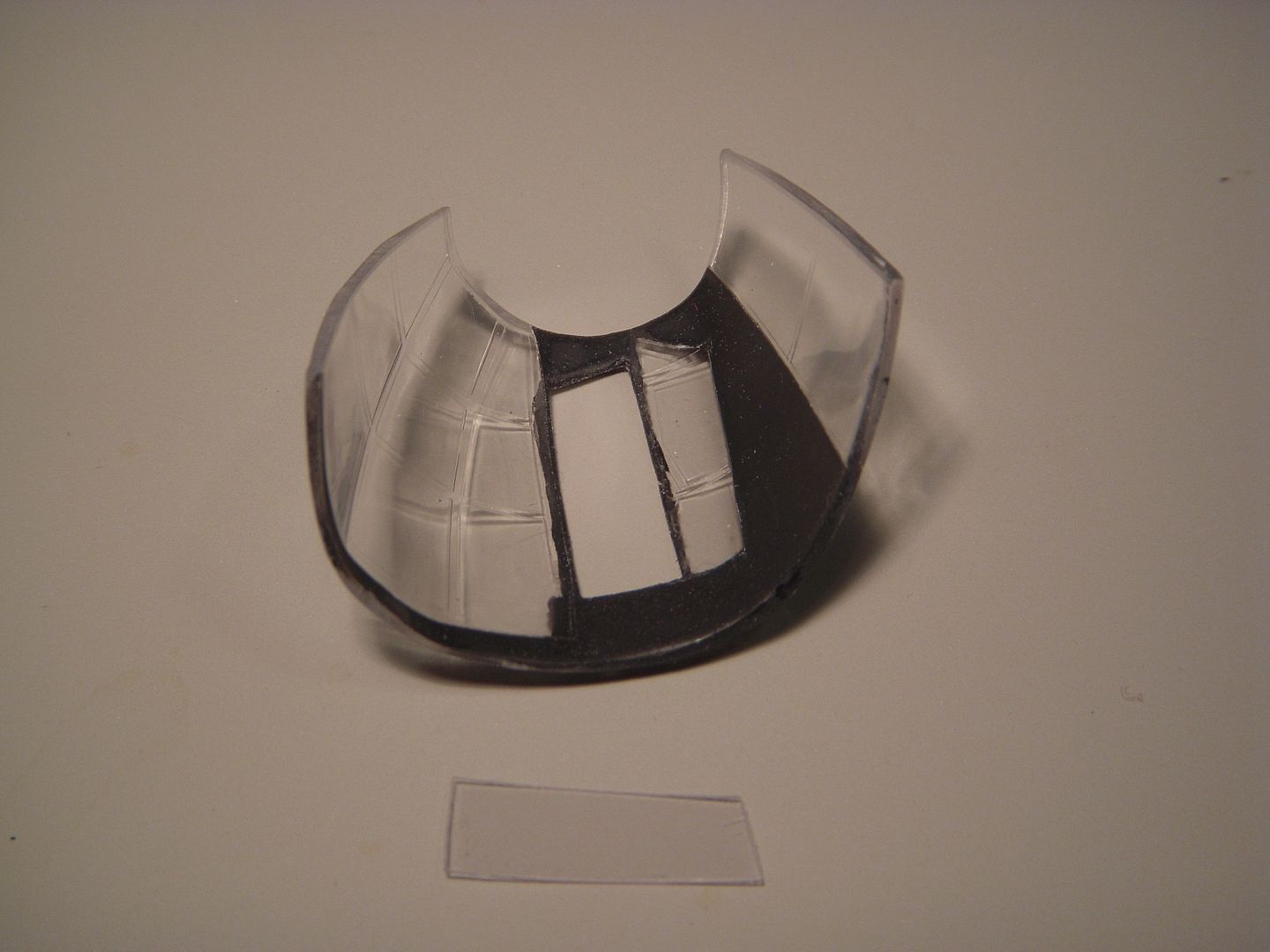

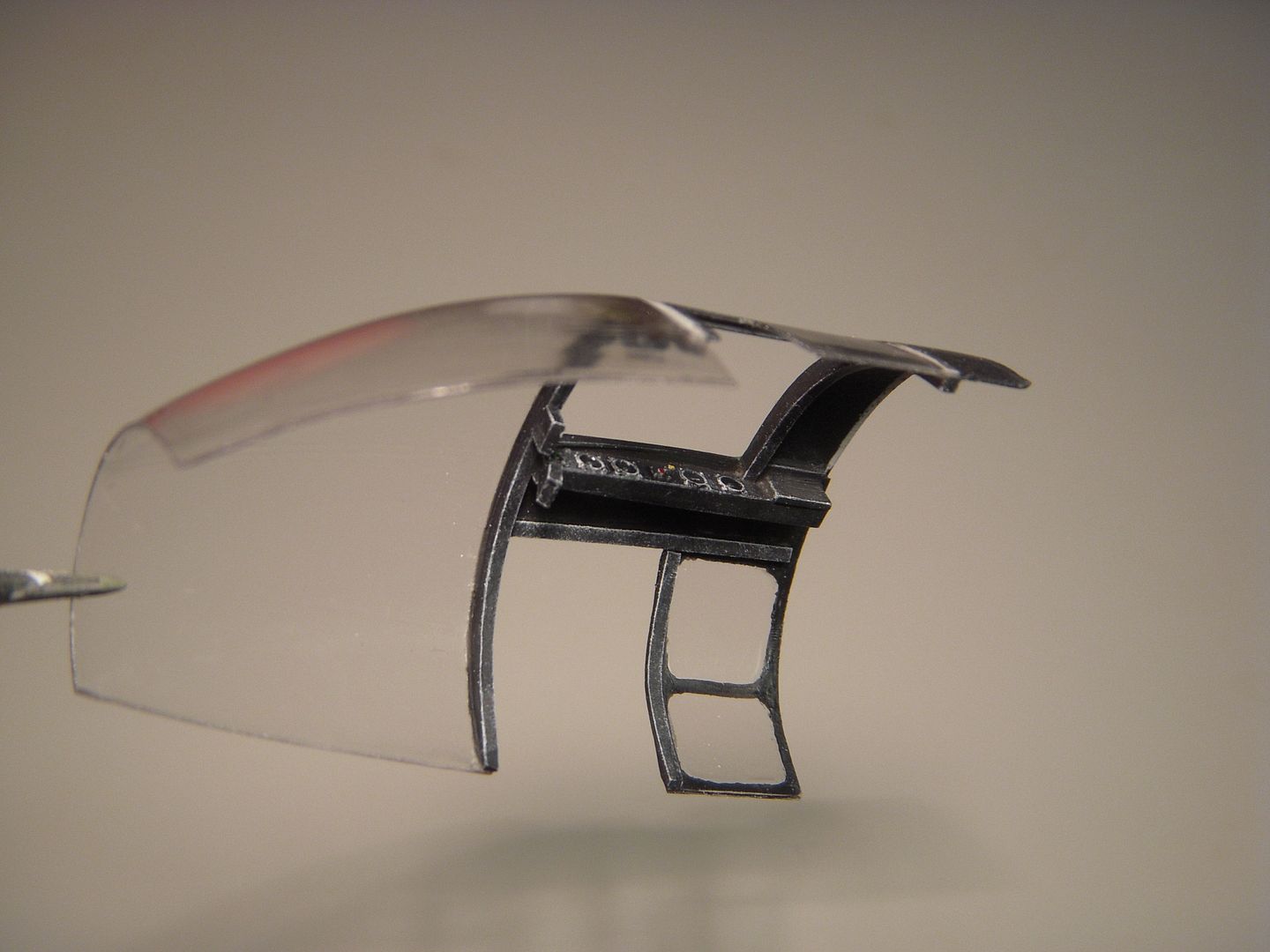

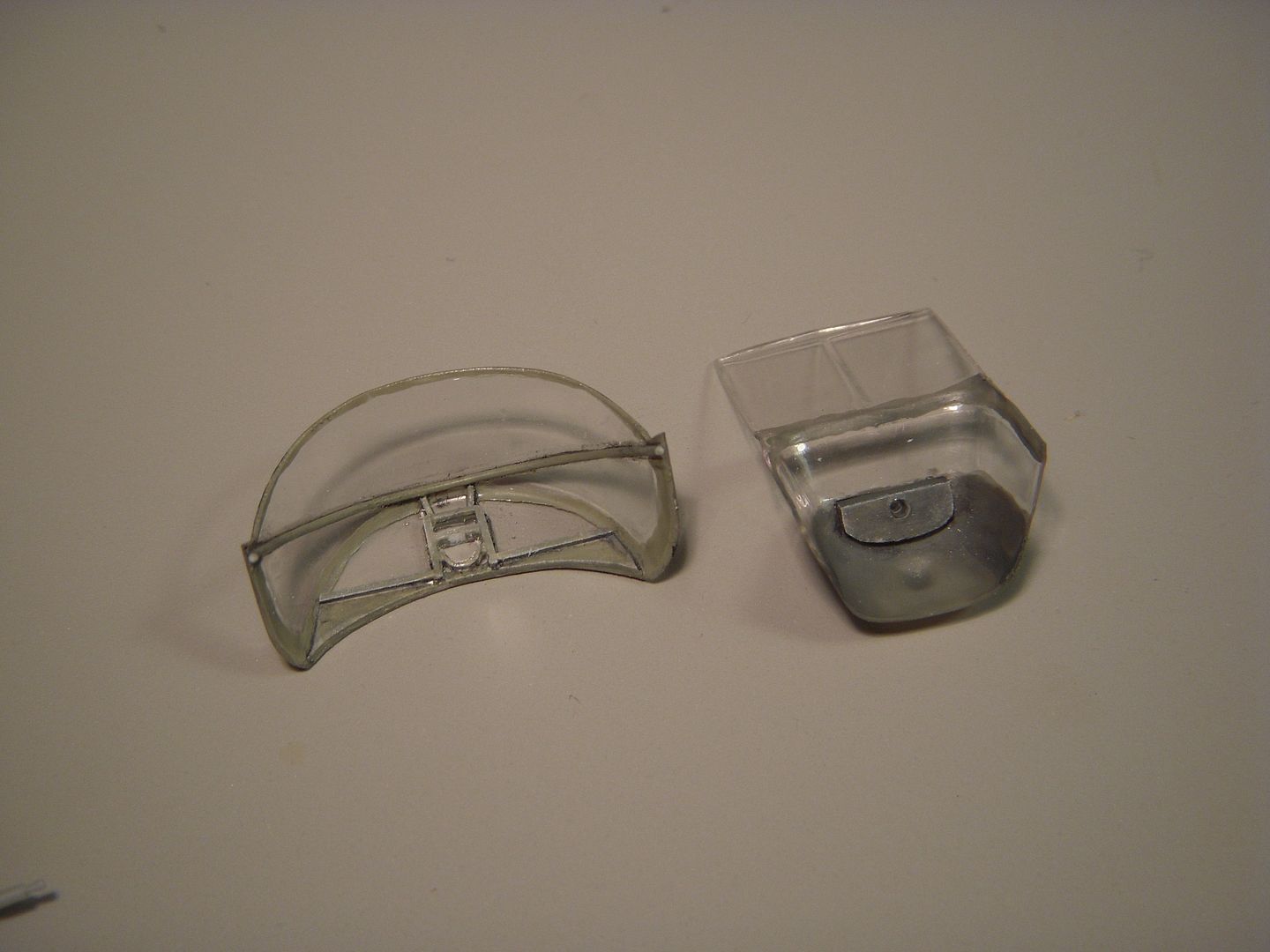

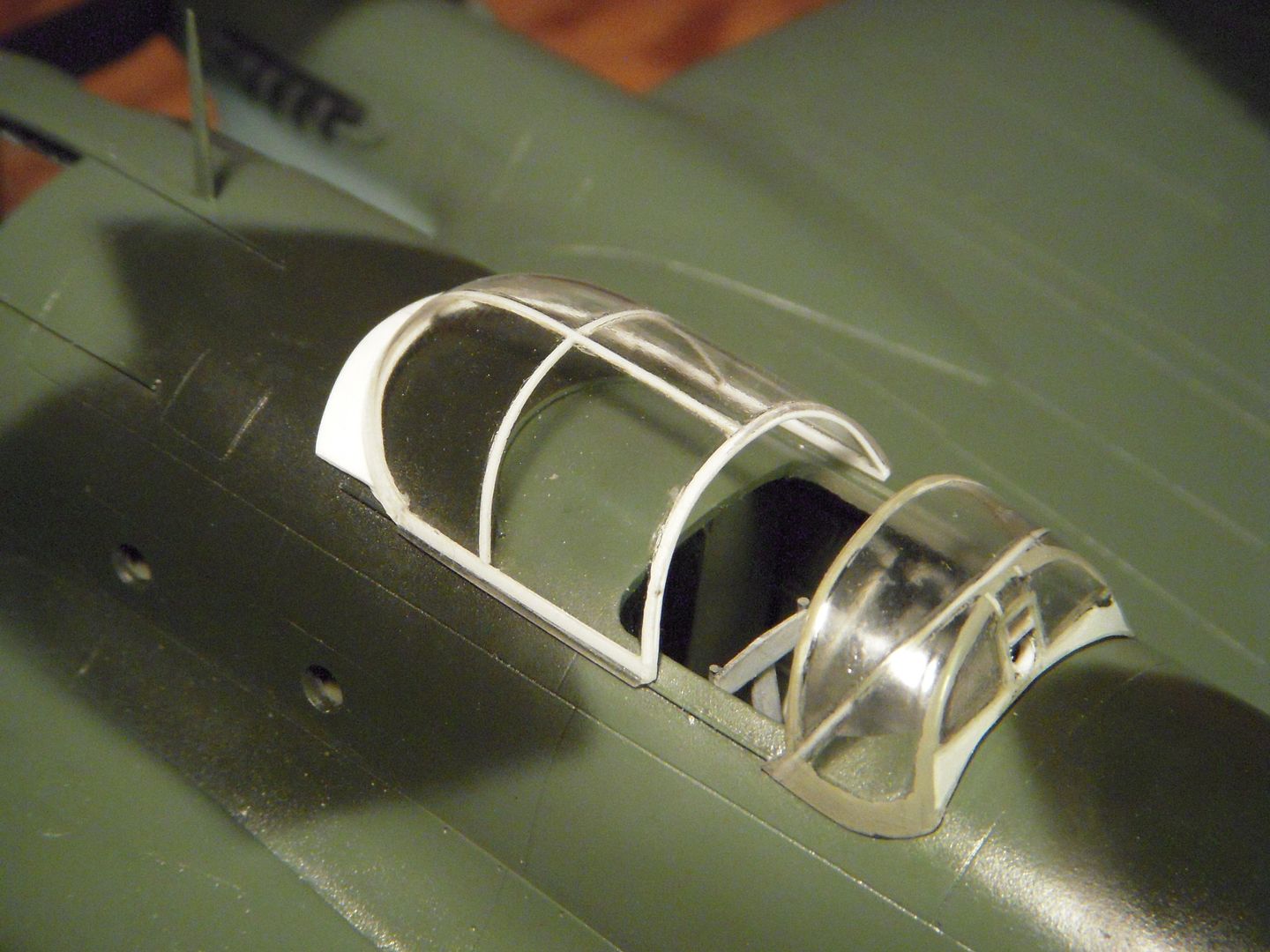

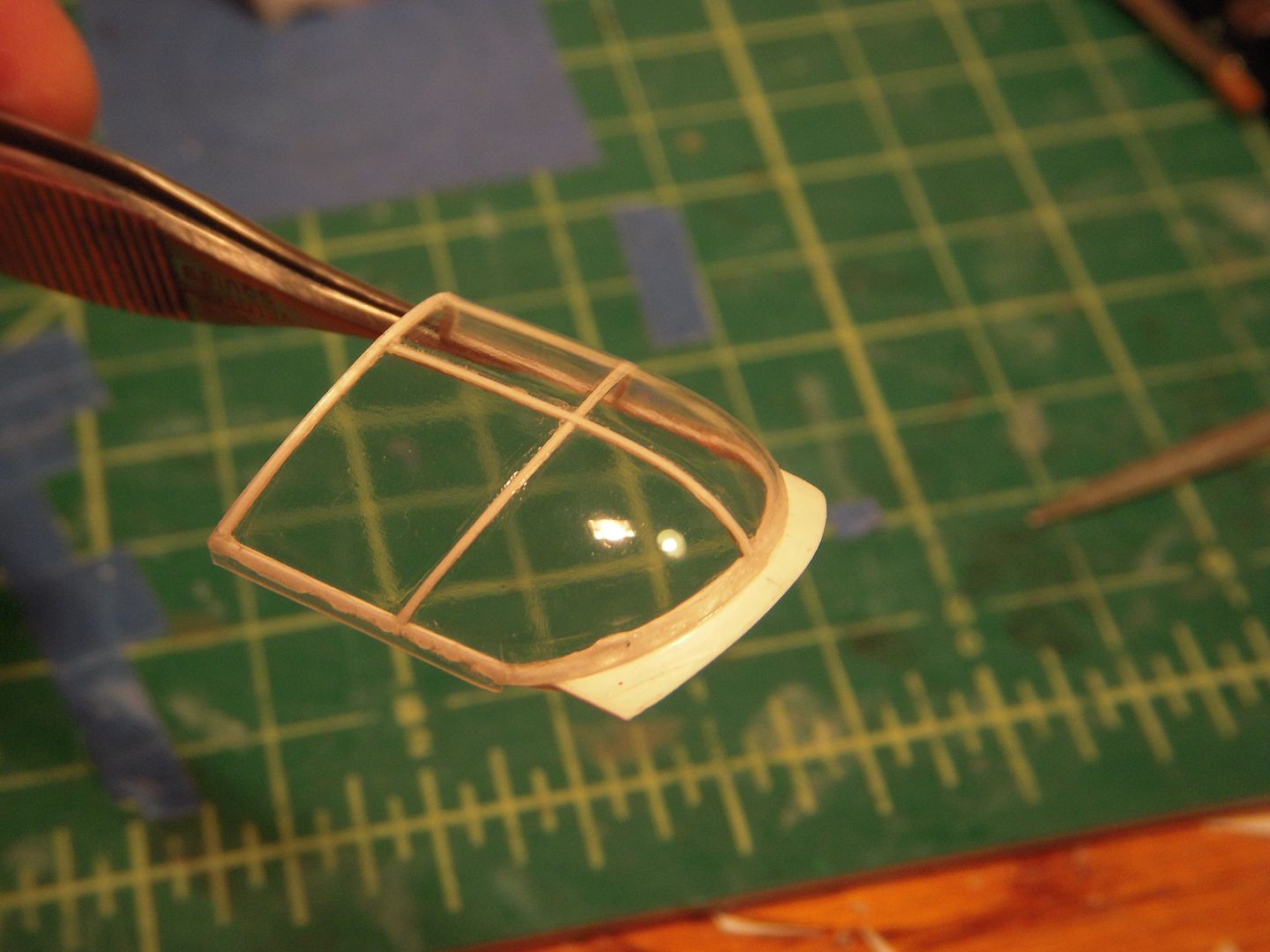

The canopy framing on the CASAs is also quite different from wartime Heinkels The vacuformed canopy set I have uses the lower part of the kit canopy, so this was CAREFULLY cut away. On the CASAs the bomb sight panel is a single simply curved glazed panel. This was marked with tape and a motor tool and files used to cut an opening. A piece of clear plastic was cut and epoxied into place.

The upper portion of the canopy glazing has been trimmed and the upper and right side hatches opened.

The entrance hatch in the gondola has been opened, the rear glazing yet to be addressed!

At long last on to the canopy installation!

I painted the inside of the lower nose framing the dark grey cockpit color before gluing the lower nose piece into place. This helps the illusion of the windows being set into frames rather than being attached on the outside.

The modification of the bomb aiming panel was successfully completed with the replacement glazing epoxied into place.

A strip of .015 X .020 styrene was carefully glued to the top edge to provide support for the vacuformed upper section.

At this point I managed to get a drop of solvent cement onto one of the panes, fortunately I was able to sand and polish it out! If you can't see which pane, I'm not going to tell!

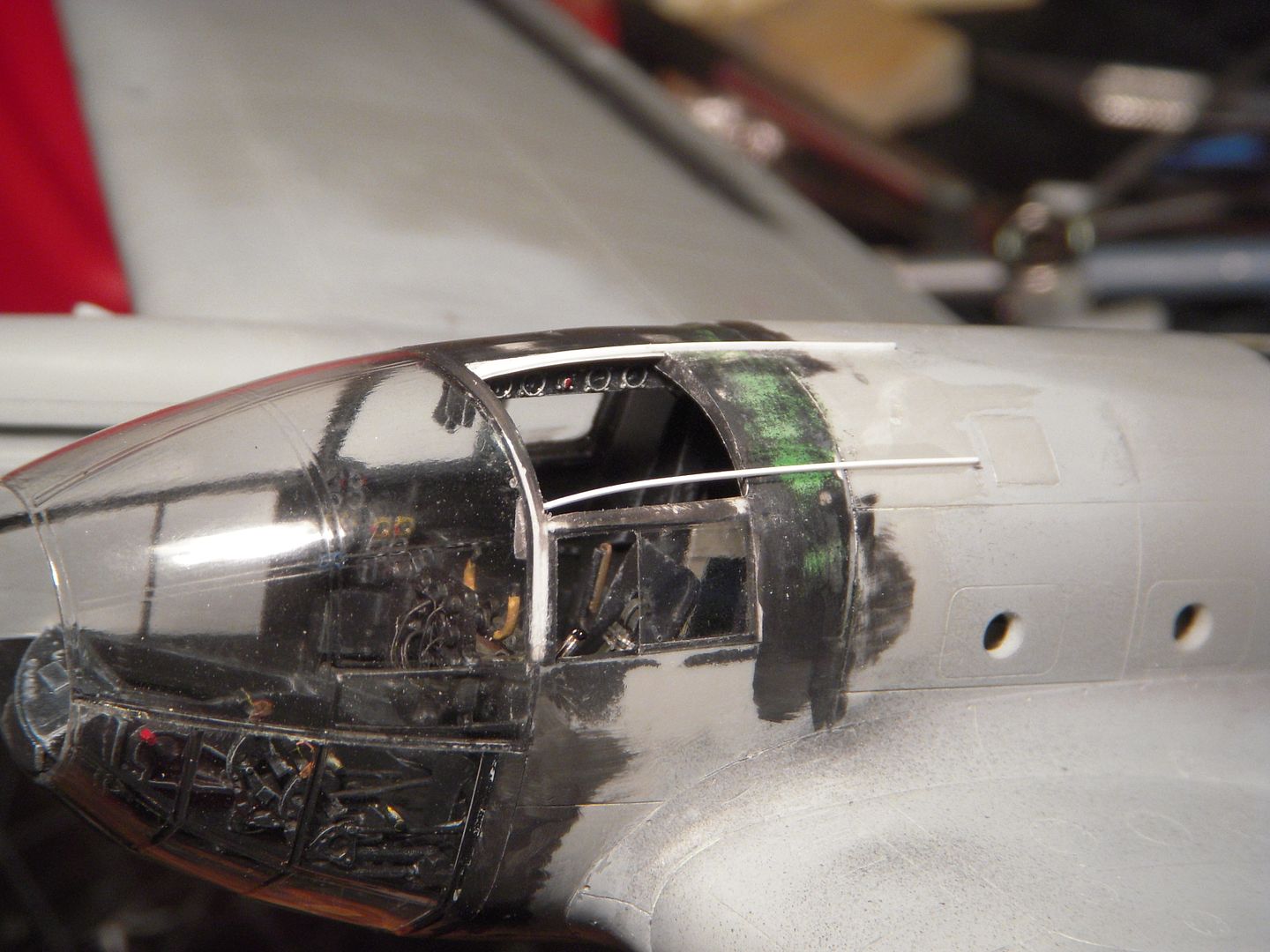

Being vacuformed, he upper section of the canopy is very thin and lacks the heavy framing found in the aft section of the cockpit. I decided to add this detail with styrene strips. As solvent type plastic glues do not work on the material used to vacuform clear canopies, I used epoxy which required some preparation. Low tack tape was used to protect the area around the frame location.

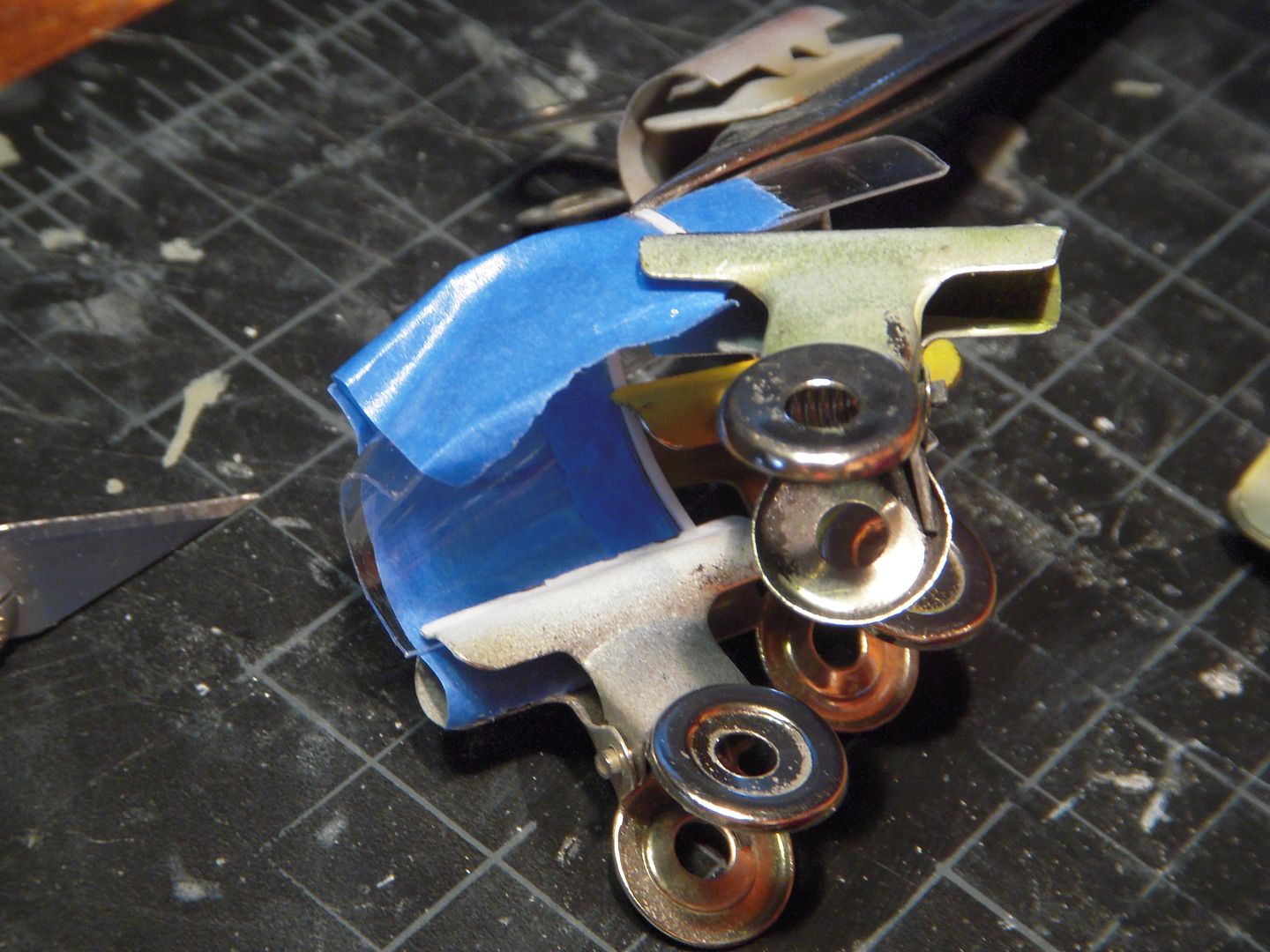

The framing was pre-bent to approximate shape and a number of clamps judiciously used to ensure the frame and glazing had no gaps.

The rest of the framing was added and the final result satisfactory.

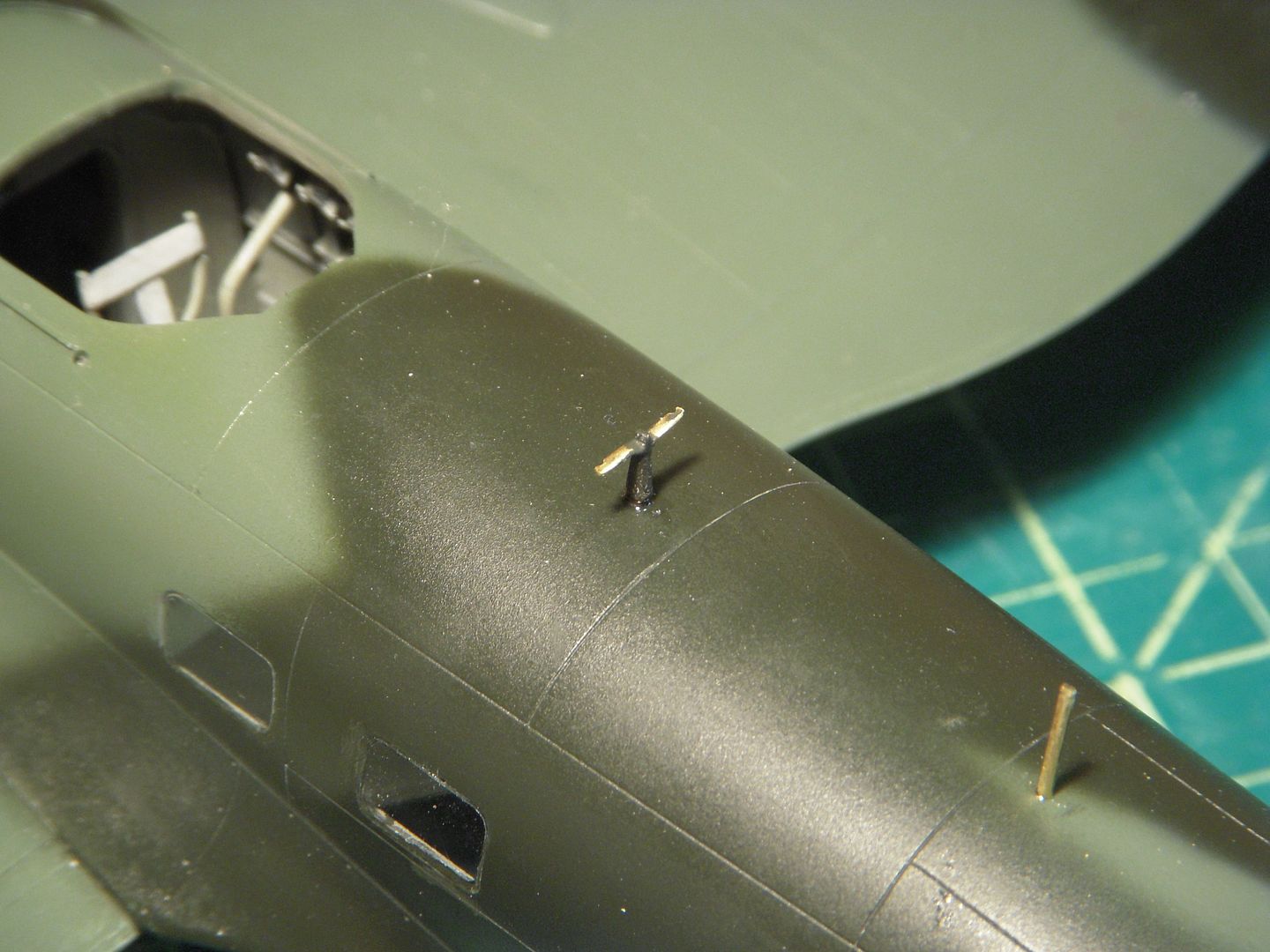

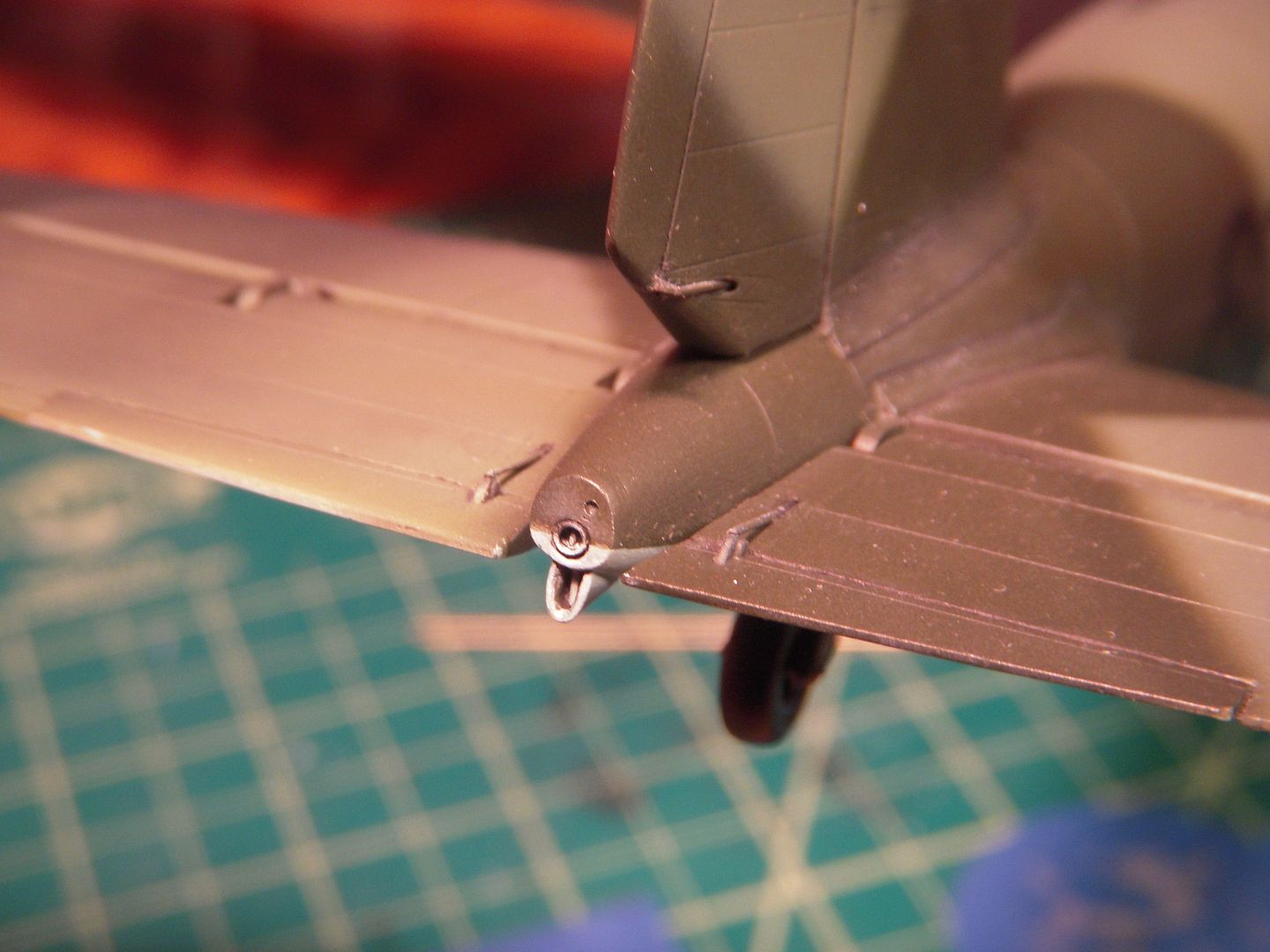

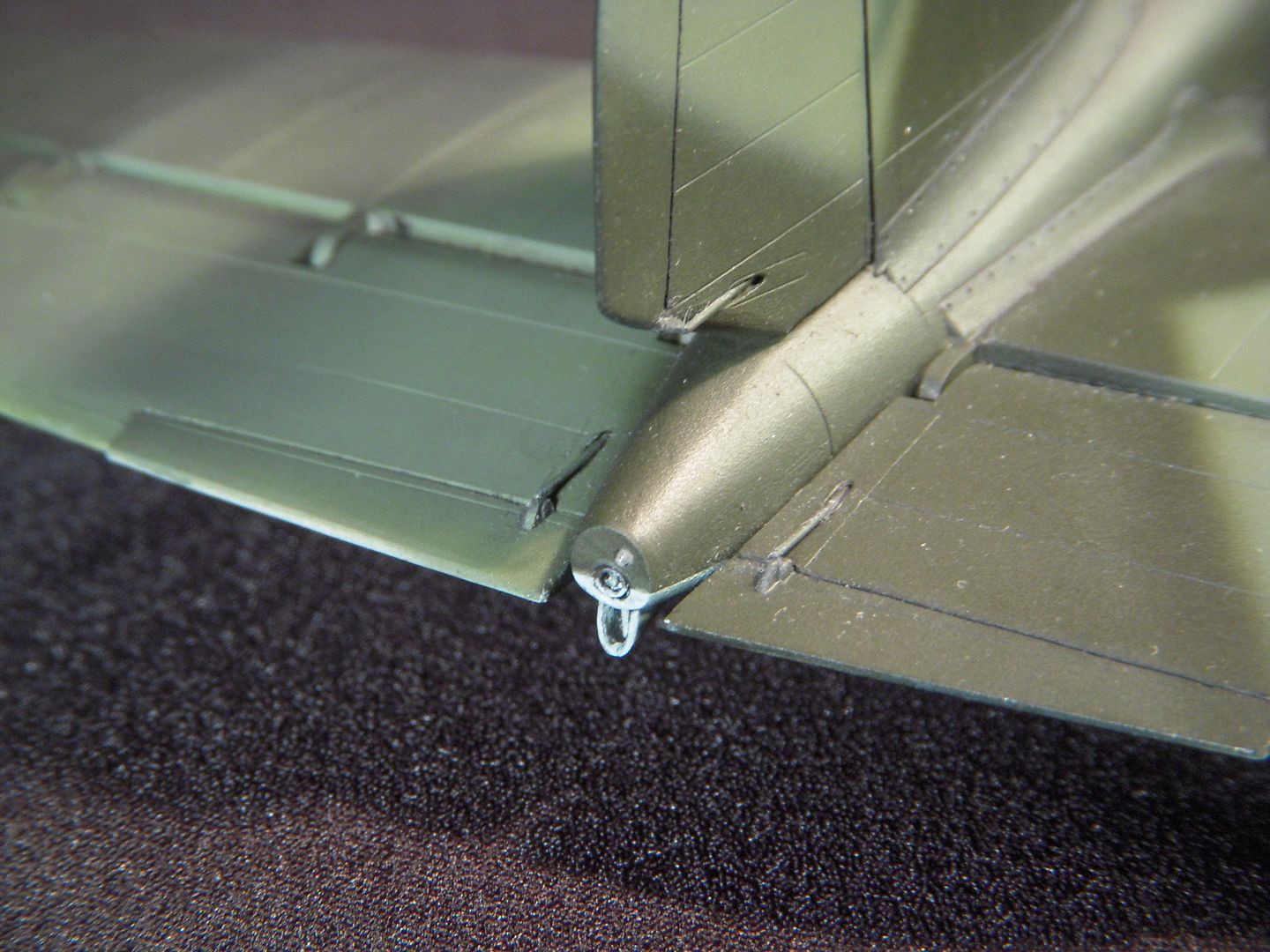

Most of the BoB CASAs had tow hooks installed so the tail cone was bobbed and a hook and housing fabricated from styrene.

Next update: Upper canopy installation

Not too much in this update, though the progress was filled with angst and approached with much trepidation! The installation of the canopy was one of the more delicate operations of the build, and I am glad to have it successfully completed.

First a bit of final detailing to the lower portion of the fuselage. The CASAs had control rod runs under the floor boards along the sides, these could be seen through the small windows (What in the world was expected to be seen from those anyway?!? in the lower sides of the fuselage. These windows did not turn out as clear as I would have wished so I reasoned that representing the control rods would help to hide this. The result was somewhat successful.

The aft portion of the cockpit had quite heavy framing, this was represented by styrene strips epoxied into place. Next, as if the three instrument panels in the lower part of the cockpit weren't enough, a few more needed to be produced! The CASAs had instruments seemingly installed as an afterthought in anyplace that happened to catch the installer's attention at the moment! An auxiliary panel was added to the overhead with individual instruments cut from instrument panels in the spare parts box.

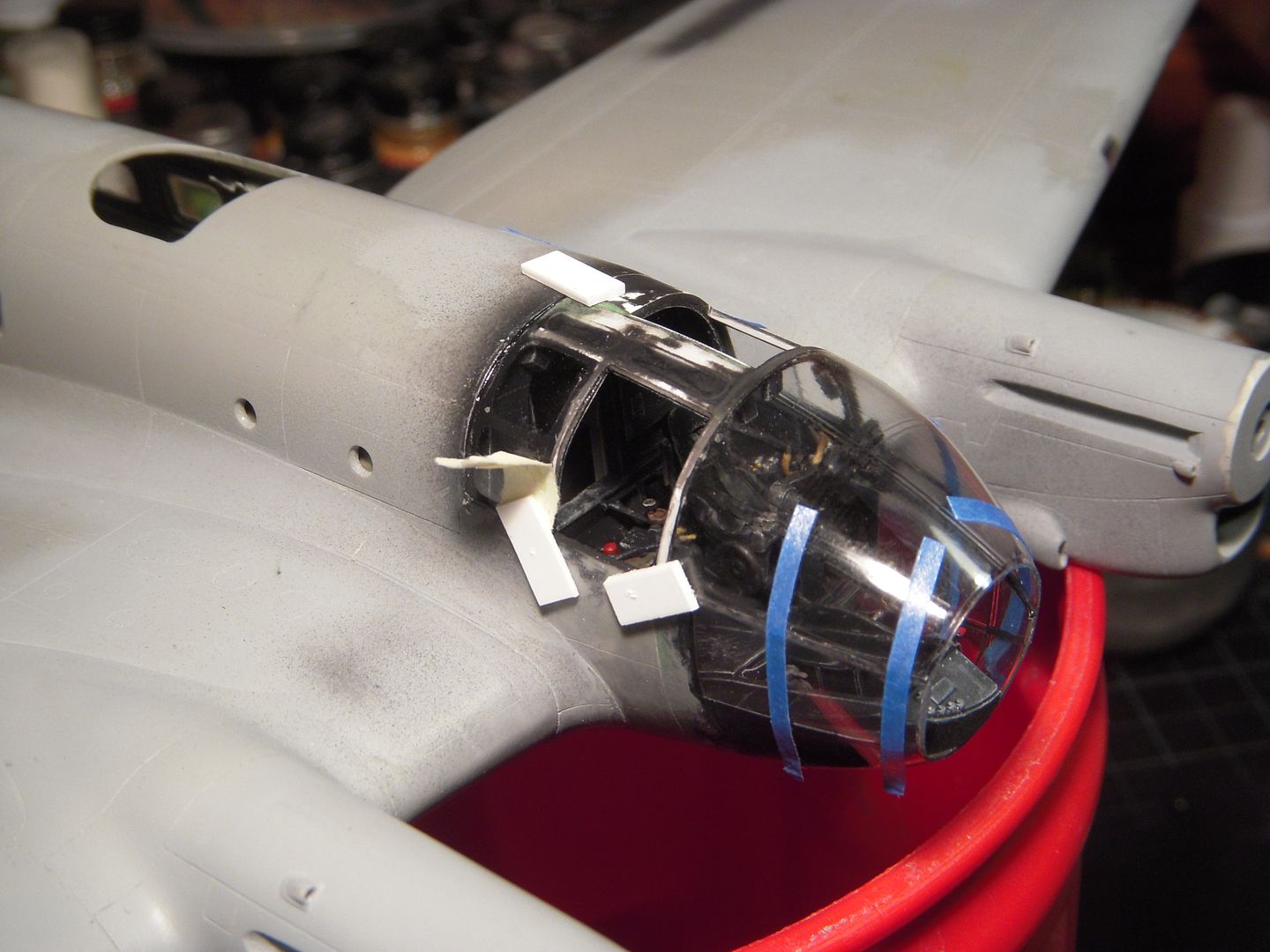

With the canopy prepared, a thin bead of epoxy was applied to the mating surface and the canopy laid into place. Strips of tape were used to hold the assembly in position as the epoxy cured. With everything lined up, the work lights were turned off before I got the urge to fiddle anymore and mess up! Do you like the fancy modeling stand?

After removing the tape the result looks promising with the mating edges fairly well aligned. I'll let the epoxy cure fully before I polish the smug marks and fingerprints. The next challenge will be masking and painting the frames.

Thanks for your interest! Eric aka The Yankymodeler

Been busy at work and with the kids last week so I've got just a bit of progress to report. The rails for the hatch over the pilot's seat have been installed, quite delicate work attaching them to the canopy in close proximity of finished parts inside the opening! The rails are .010 X.020 styrene strips pre-bent to shape. A thin bulkhead was fabricated with a curve to match the rail and was carefully glued to a lip projecting from the instrument panel on the right upper side of the roof of the cockpit. This provides a "channel" effect and allows the front of the hatch to seat properly when closed. The rail on the left side was a bit harder as the rail was mounted perpendicular to the fuselage and needed to curve in two planes in order to remain parallel to the rail on the right! The rail was pre-bent (with much trial and error) and installed. It's supporting bulkhead cut to fit the space between the rail and the canopy and very carefully glued into place. After painting the rails they are a reasonable representation when compared to my references.

The dorsal position fixed portion was detailed with styrene to represent the heavy framed armored glass. After painting, a wash and highlighting, it too compares well with references.

The rails for the sliding part again are .010 X .020 strips easily glued into position. The curved piece is a water deflector that channels any rain that gets under the front of the canopy around the gunner's opening.

The ventral position will somewhat visible through the open upper position so it received styrene armor plate as much to detail as to provide a secure mounting for the gun.

The guns were modified to better match the armament seen in the movie by the simple expedient of moving the grip and trigger to the rear of the weapon. Although not a perfect replica, the result is again a reasonable representation.

Getting very close to paint now, the next challenge will be to match the 'movie make-up'. Thanks for looking, Eric aka The Yankymodeler

Nothing dramatic to show in the way of progress I'm afraid, but I have gotten most of the fiddly bits done. Trim tab actuators on the elevators, rudder and ailerons, servo tabs on the ailerons were fabricated from styrene bits and stretched sprue. The two large tube tubes located on the underside of the wing just in front of the ailerons are styrene rod with the end drilled out. Does anybody know what they are? My guess is fuel dump pipes.

On the real CASA's reinforcing strips are seen on first two sets of bomb bay doors, these have been added with styrene strips.

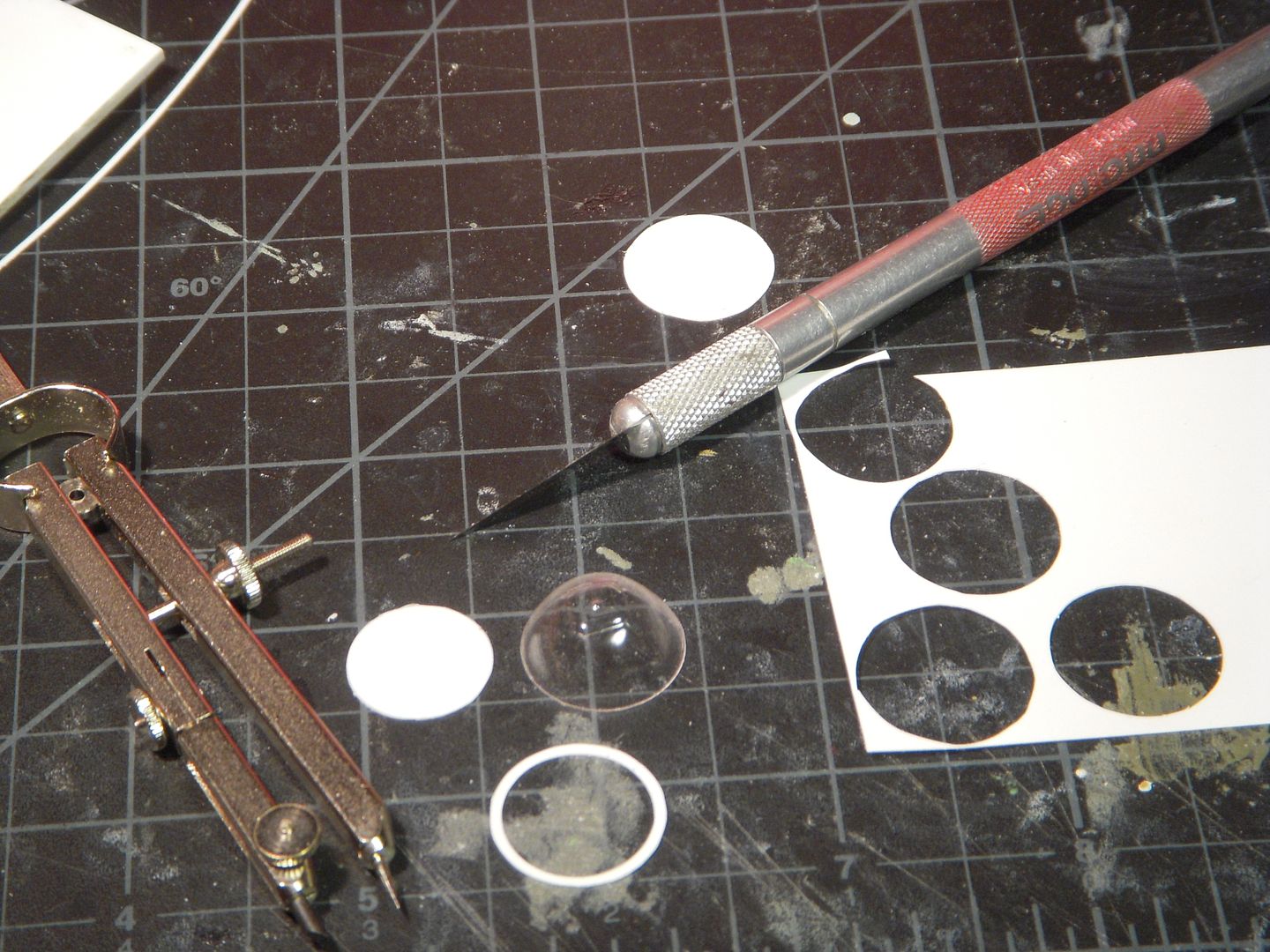

Hopefully nearing the end of working on clear parts, the nose bowl was cut from it's sheet and trued up. The forward gun was fitted to a substantial mount that allowed for elevation and transverse movement. A frame and flexible mount similar to that in the dorsal position was made from styrene, installed with epoxy and painted. On the real aircraft the nose bowl was mounted to the rest of the nose by a flange. Not only is the flange quite noticeable but the increased surface area will make attaching the thin walled vacuformed parts easier. The inside and outside diameter of the circle were marked with a compass on a sheet of styrene and carefully cut out. A little sanding smoothed the edges and the flange was painted and epoxied to the nose bowl. I'm pretty happy with the end product.

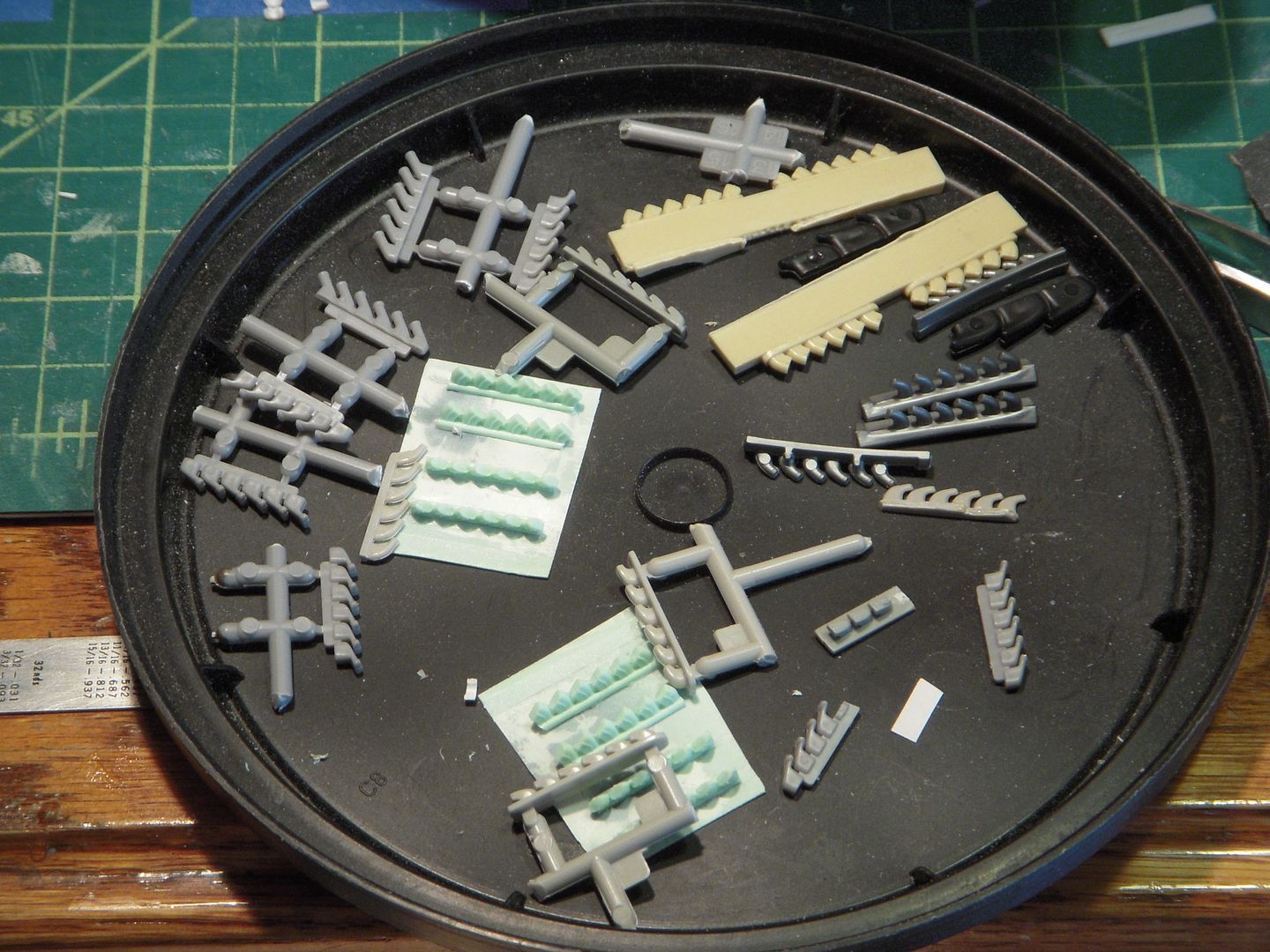

At this point the work bench had become a bit too cluttered to work on and a cleanup was required before going any further!

The prominent shrouds around the exhaust manifolds were a bit of an adventure. Appearing fairly simple at first I soon realized the shape is quite complex as I began construction. The shrouds are a box that is tapered and flares outward. The depth of the 'box' is not constant but is narrower at the front to conform to the taper of the cowling. I ended up making a couple of prototypes refining the shape each time until a reasonable representation was obtained. (My apologies to the rivet counters out there :poke: ) The flare was made by scraping the sides with the blade of a knife and a bit of file work.

The openings in the nacelle were too large for the CASA, and were closed up with styrene. After a bit of trimming and shimming, the shroud to nacelle fit turned out quite good.

Masking the extensive glazing has begun, next step is to start getting some paint on these two. This may take a while, don't forget there are two CASA's under construction!

Thanks for your interest! Eric aka The Yankymodeler

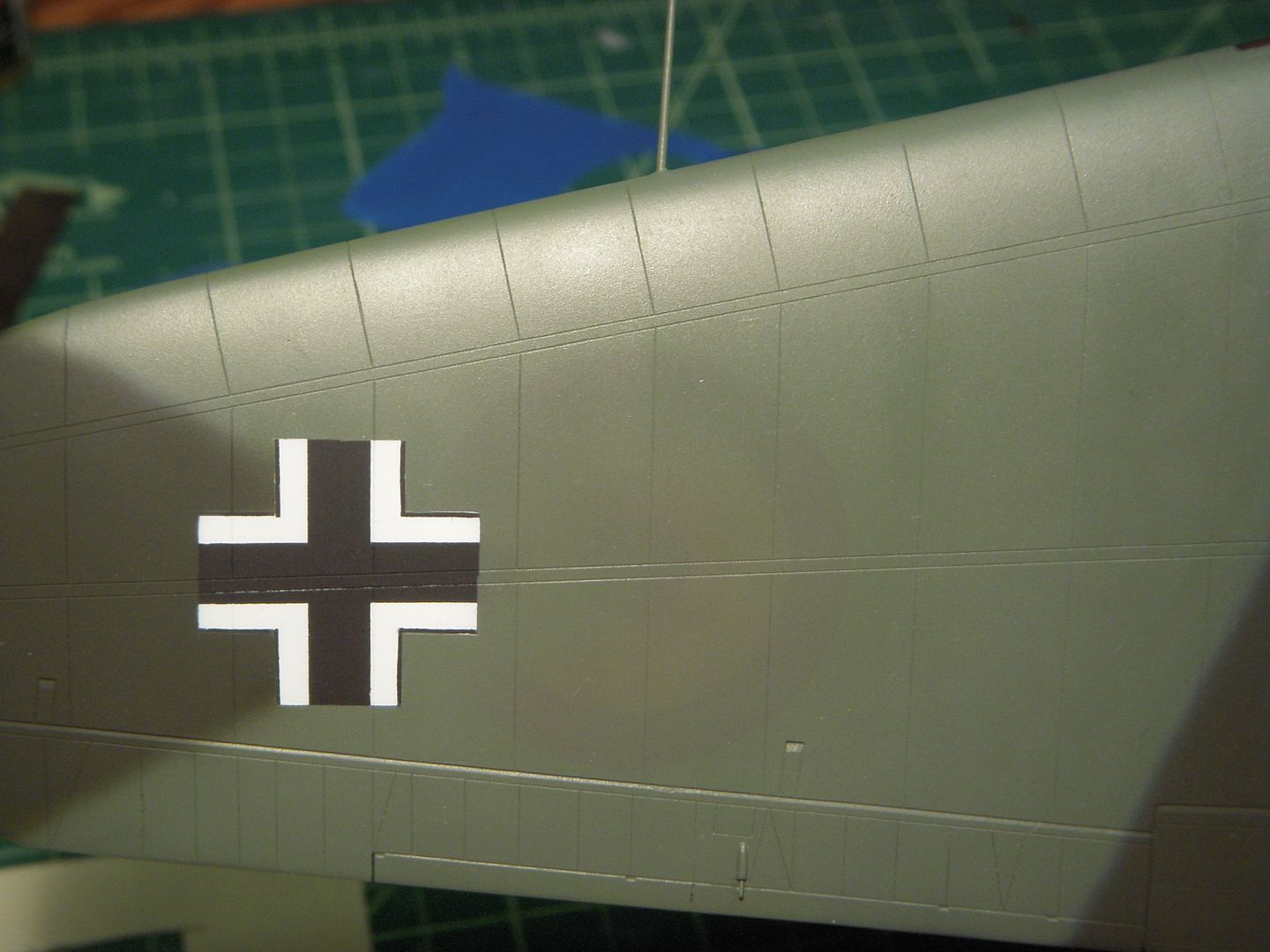

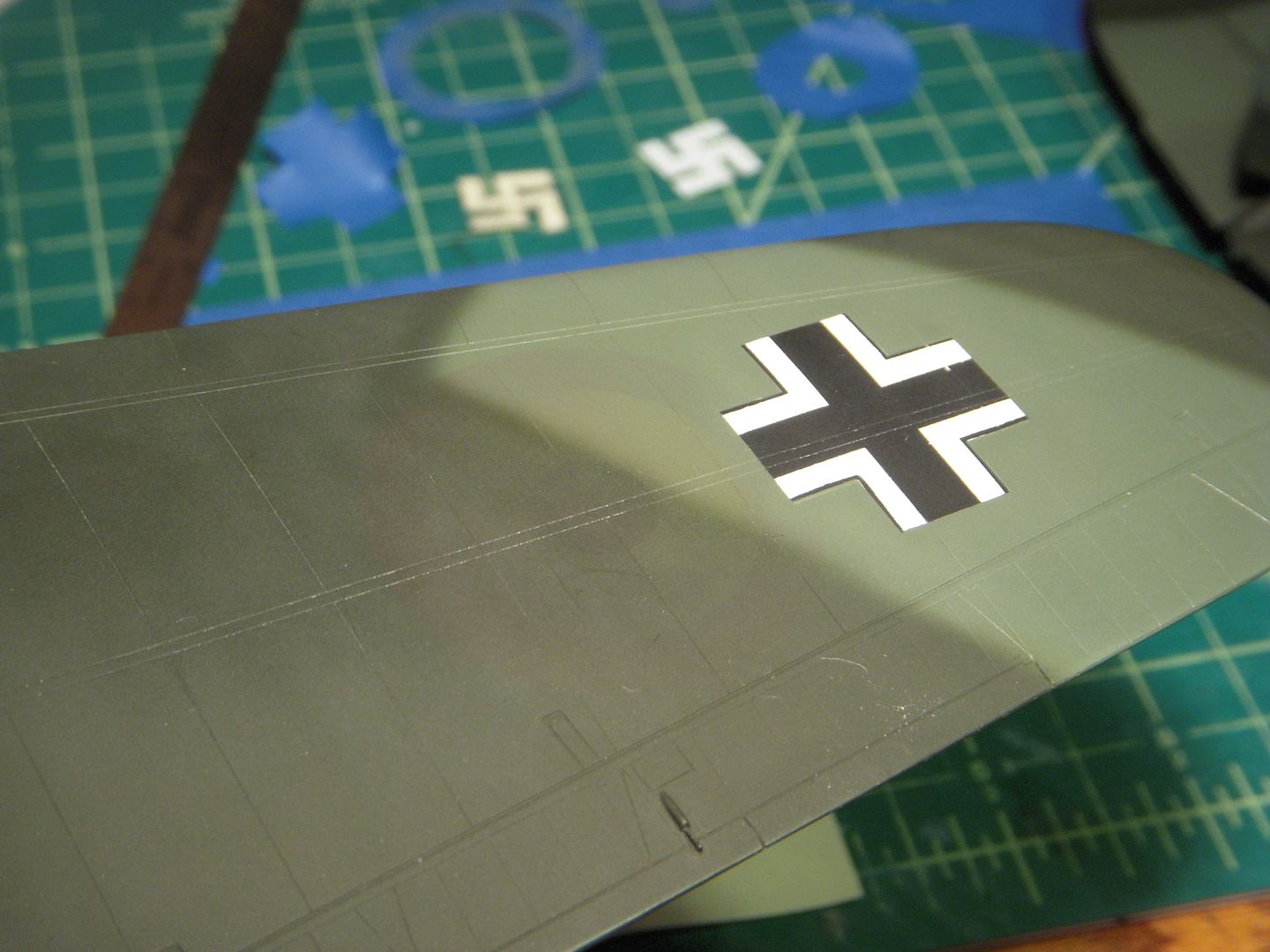

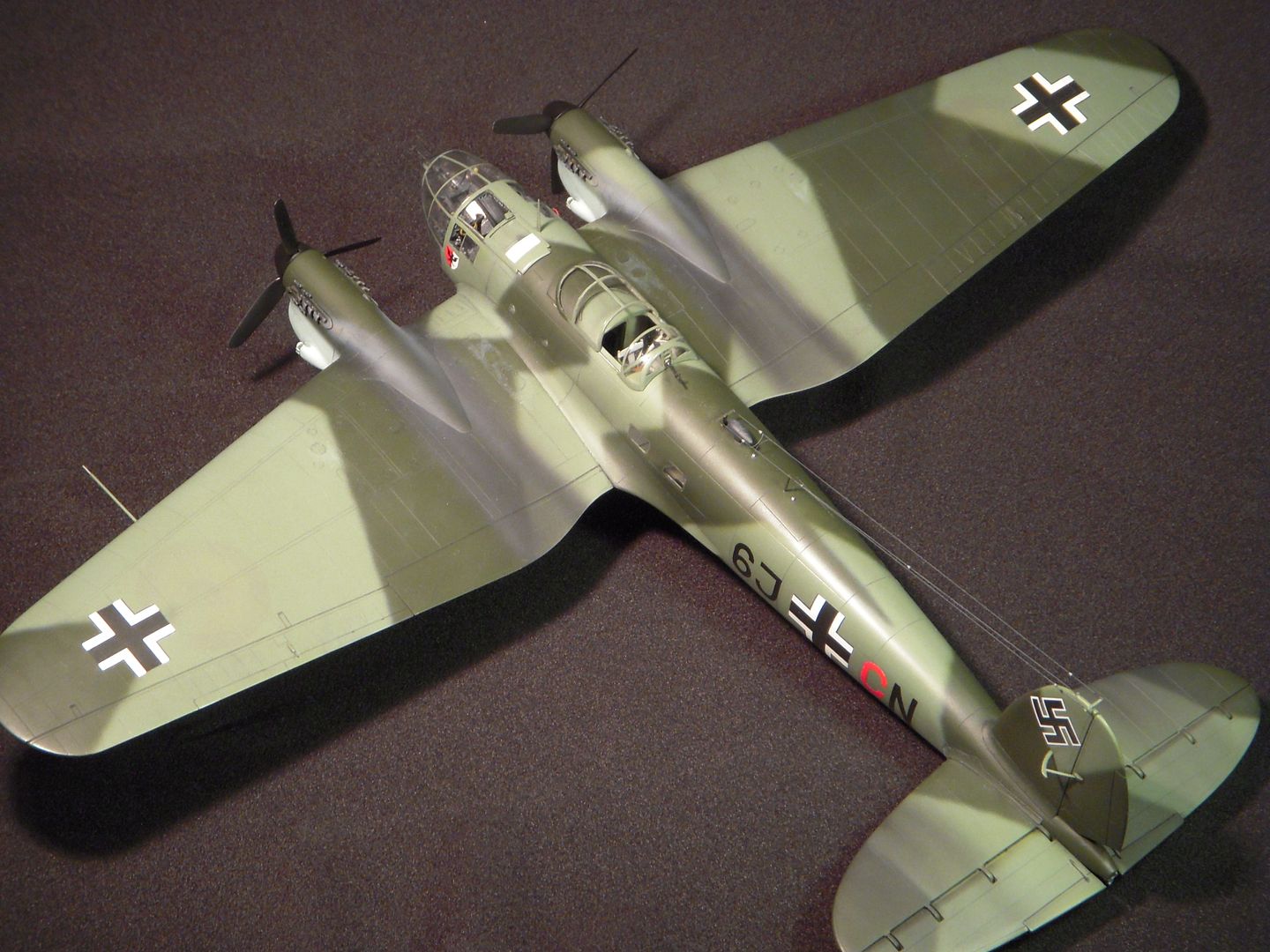

Sorry chaps, it's been awhile since the last update. I've been trying to finish an addition/remodel project on our home and spring has come early to the Shenandoah valley so modelling time is becoming scarce. The CASAs are out of the paint shop, once again a process that took far longer than I anticipated! (what else is new?) I venture cautiously into the volatile subject of color here. These models represent aircraft used to film the movie "The Battle of Britain". Using both my DVD copy of the movie and still photographs from a number of sources, I attempted to mix colors that matched the aircraft as as they appeared off camera. This, as usual, proved more difficult than I anticipated because the aircraft were frequently repainted and touched up throughout the filming. The pattern was also matched to the film aircraft, this fortunately was very consistent as it allowed for continuity on screen. A couple of iterations of both colors and patterns were needed to get the desired result.

A lot of time was spent masking the extensive glazing. The CASAs featured framing that was quite different from Heinkel built aircraft careful inspection of pictures was necessary to get the framing correct. Dark grey was sprayed first so the inside of the frames matched the cockpit colors. The grey on the airframe is not preshading (I'm not a fan of this technique myself) but simply my being lazy and using the same paint to check my sanding!

Into the paint shop

My technique is to spray the large areas first then refine the edges. Here is the final color before the fine work.

That's quite a pile of masking materials, no wonder it took me a couple of sessions to mask both models!

A lot of light blue paint there!

The final result looks pretty good. There is some touch-up and clean-up work on the canopies yet to do.

Thanks for your interest! Next up are makings and weathering.

Eric aka The Yankymodeler

Thanks for your interest!

Thank you for all the kind comments! A bit of progress has been made. Some cleanup work on the canopy framing with a sharpened toothpick and touch up with a fine brush got the canopies to a presentable state. I did manage to pop a seam loose, but got it glued back without harming anything. The exhaust shrouds were painted and glued into place, the manifolds and stacks will be fabricated and added very close to completion.

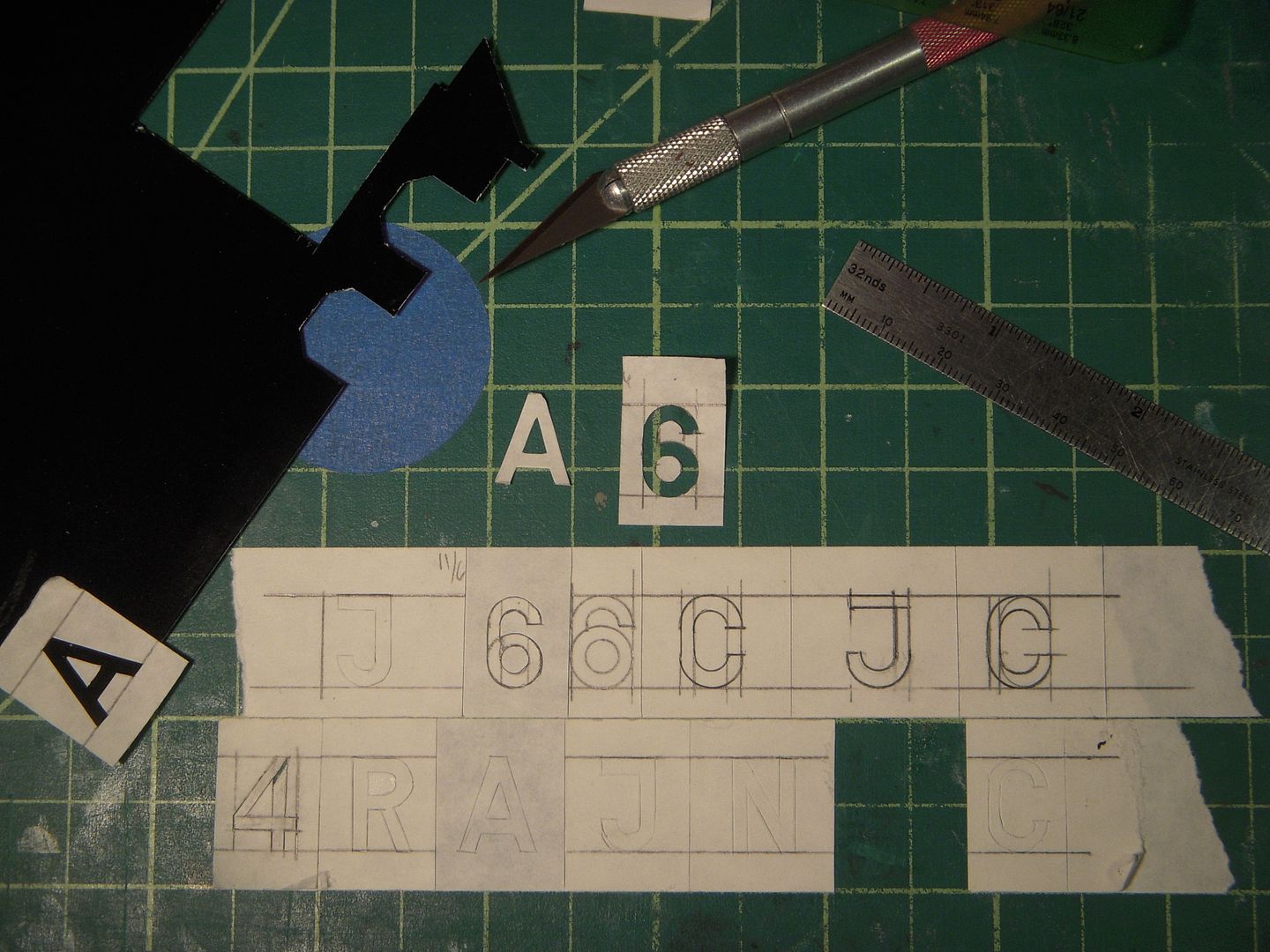

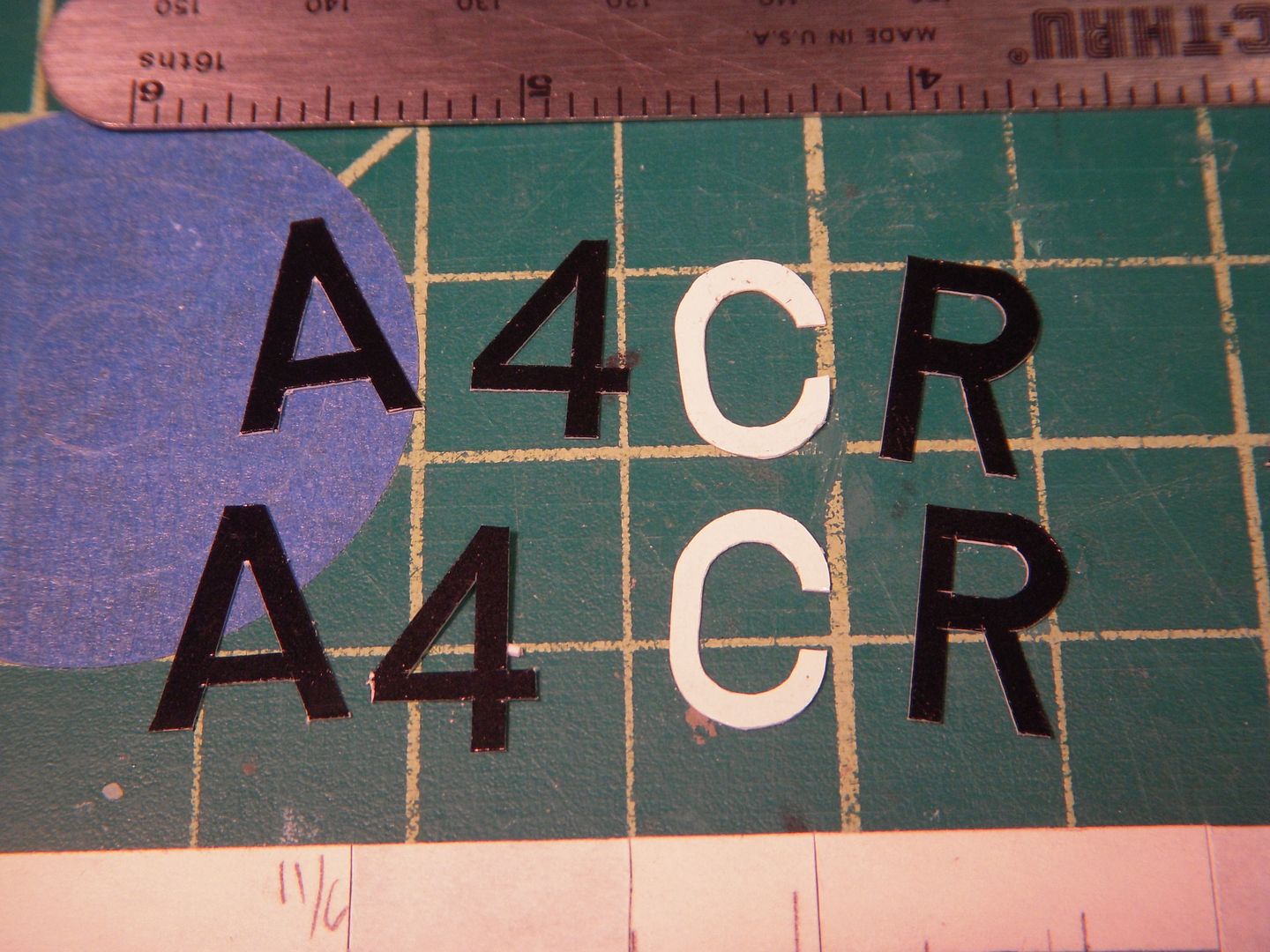

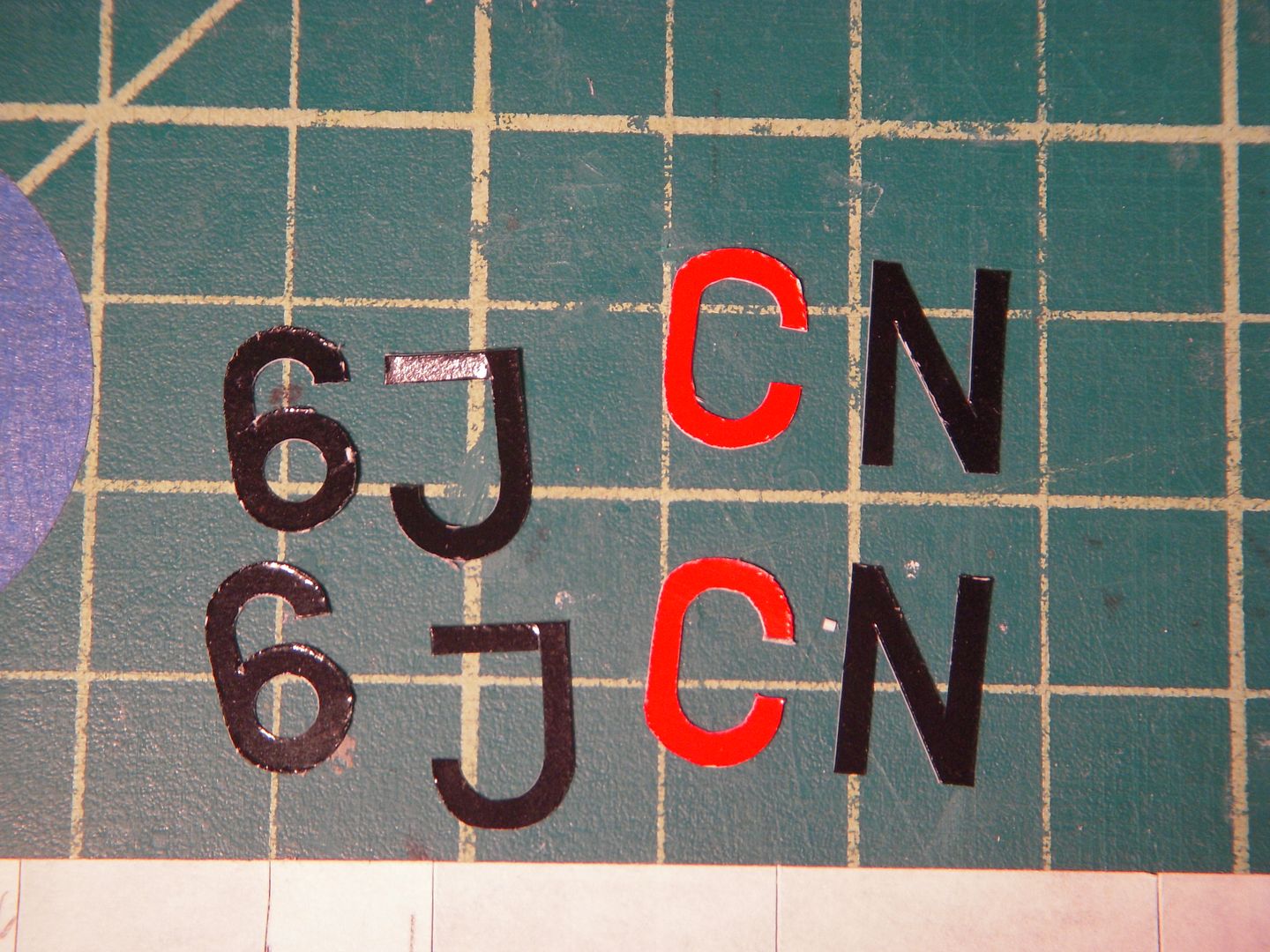

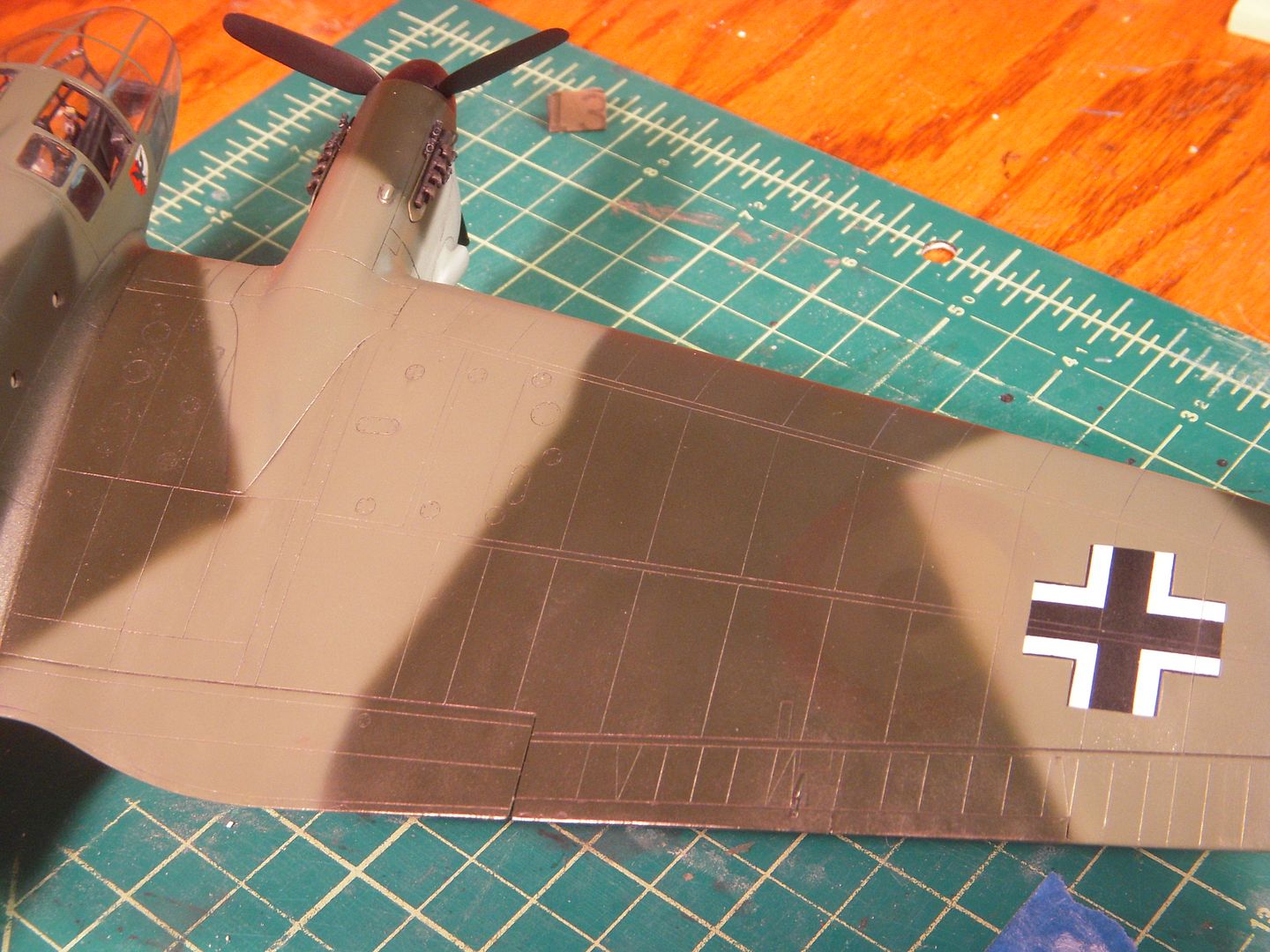

In preparation for applying markings, I came to the realization that not only was the kit markings for late war period, but I had no replacements in the stash and couldn't find appropriate after market replacements! In studying the movie and still photographs, I also noticed in many of the shots the Spanish roundels showed faintly through the paint on the upper surface of the wings. I think this feature so iconic of the film I just had to try and reproduce the effect. Also, if I painted the national markings I could reproduce the effect of the stick-on squadron codes used on the film aircraft. Stencils for both the Spanish and German markings where cut from low tack tape using a circle cutter and straight edge.

The German national markings were painted using layers of masks and still need a bit of touch up with a fine brush.

The Spanish national markings of red and yellow roundels were lightly sprayed with a very thin mixture, and then a light coat of the camouflage color was sprayed on top to get the desired effect. Difficult to photograph, the Spanish colors can be faintly seen through the movie paint .

The paint patterns on the film CASAs were quite consistent and I've tried to do the same. From a distance I think I've been fairly successful.

Thank you again to those still following this drawn out project. Your support has helped keep these from the shelf of doom! Modeling time is becoming a premium as spring arrives early in the northern Shenandoah valley and summer activities compete for my attention. I hope to have these completed in time for the IPMS Nationals in Orlando this year. Still a long way to go though!

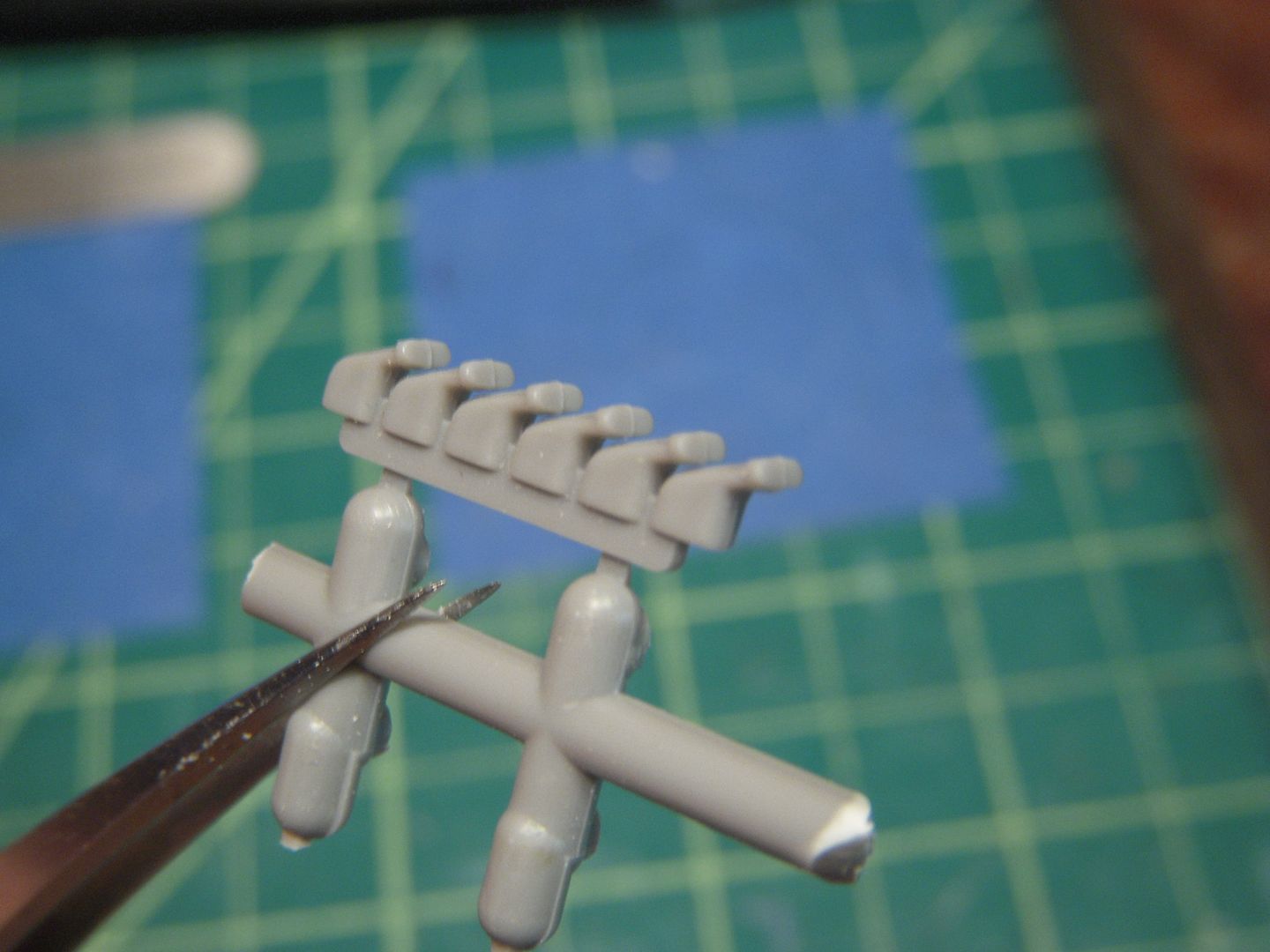

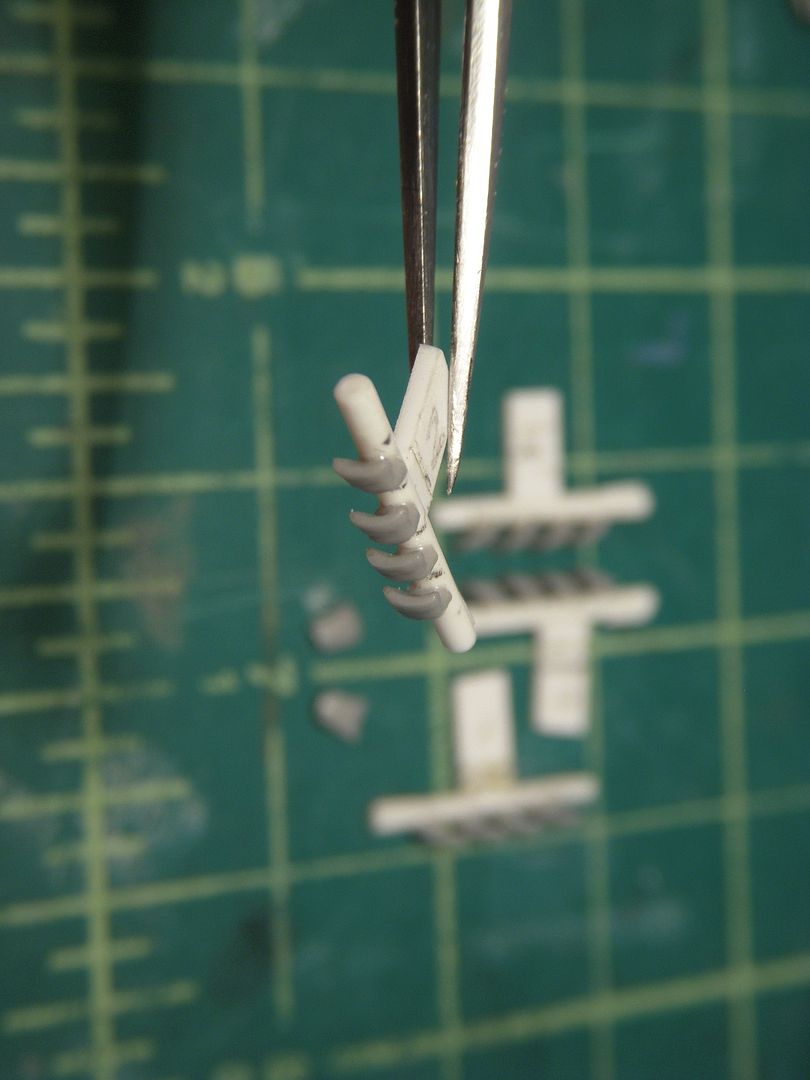

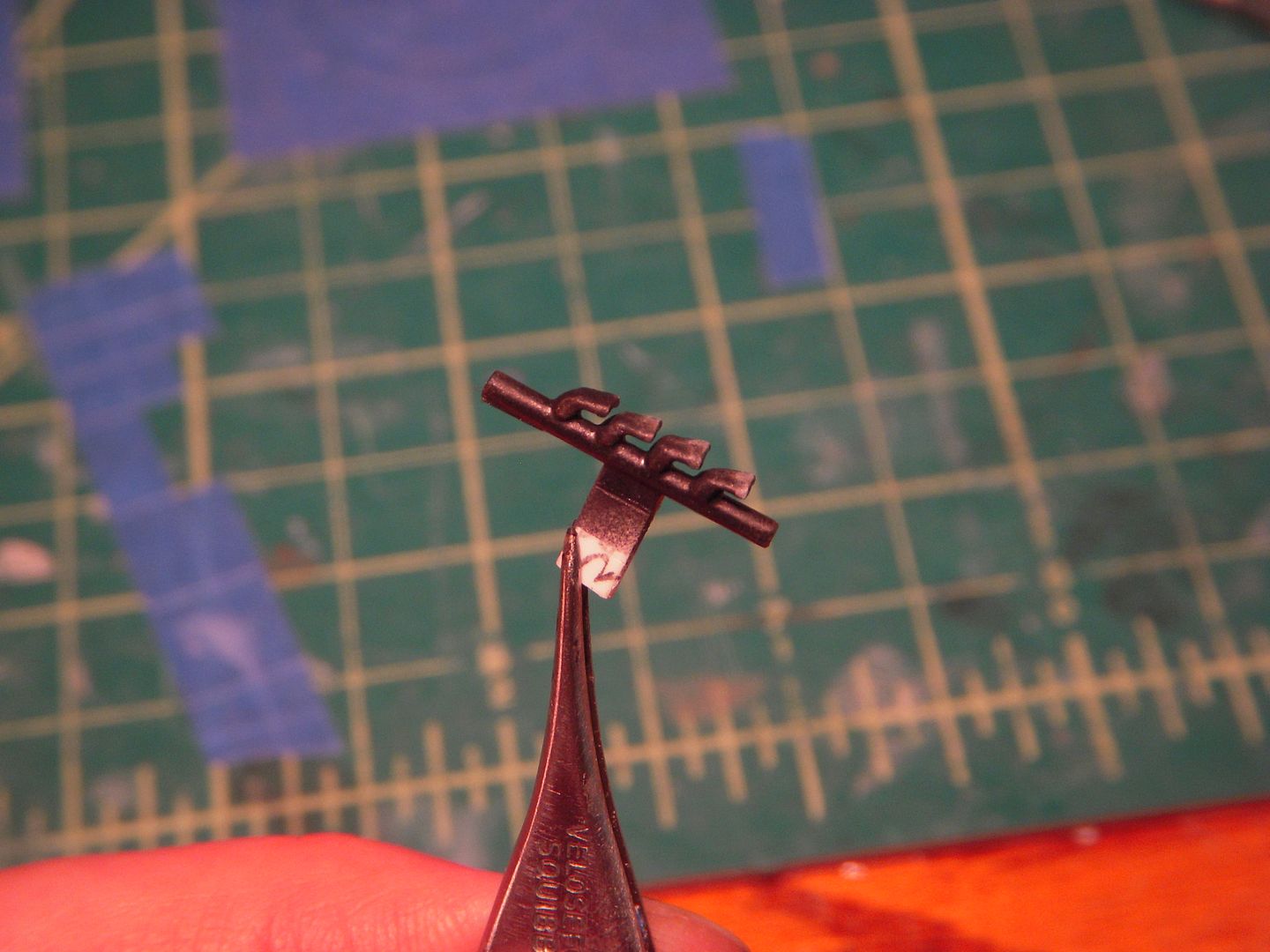

A small update this time for those hearty enough to continue following my glacial progress. I have to say here how much I admire those builders who can turn out masterpieces in seemingly a blink of an eye! :worthy: I spent quite some time digging through my decal boxes searching for proper sized codes in vain. I will be making up some stencils as soon as I decide on which of the myriad of codes worn by these supporting actresses catch my fancy. In the meantime I turned to replicating the unusual exhaust system used on the CASAs. At first glance appearing like individual 'fishtail' stacks, closer inspection reveals not the expected six outlets on each side, but only four, and these are spaced in the center of a large manifold. I thought no problem, I have a large selection of exhausts left over from the Spitfires and Hurricane builds, I can simply cut off the needed number of stacks and glue those to a manifold made from styrene rod. Surveying the available stacks it was soon obvious none had the curved outlets needed to replicate the distinctive exhaust system.

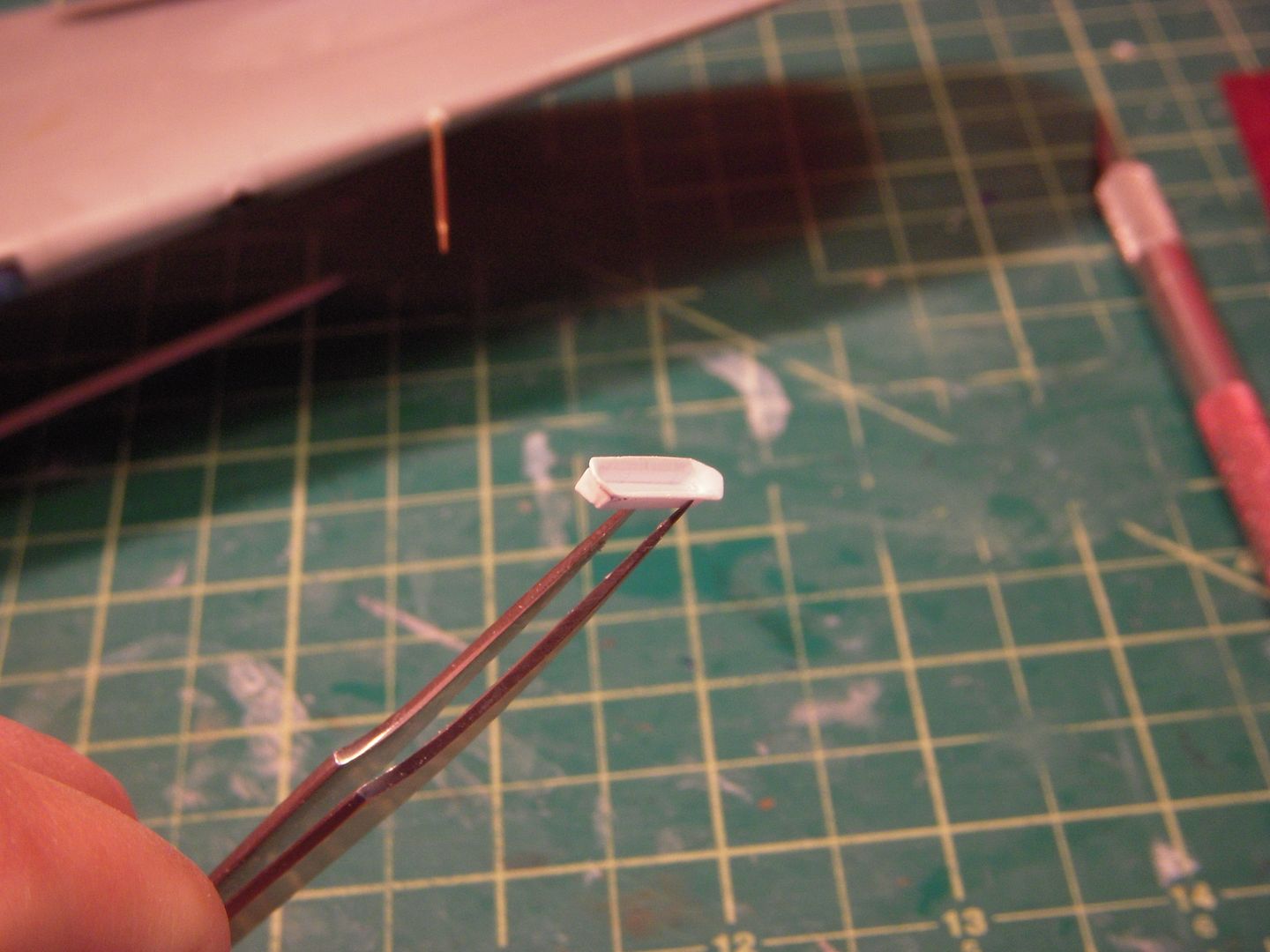

At first I tried to cut and carve the stacks from rod and tube, but was unable to capture the right shape nor make more than one the same! I finally turned to modifying a couple sets of 'fishtail' stacks from Hasegawa Spitfire Mk IX kits.First a file was used to curve the lower/inner surface of the outlet, then the top/outer surface is filed to shape.

A properly sized section is cut from the blank and shaped.

A curve is filed into the base to conform to the tubular manifold.

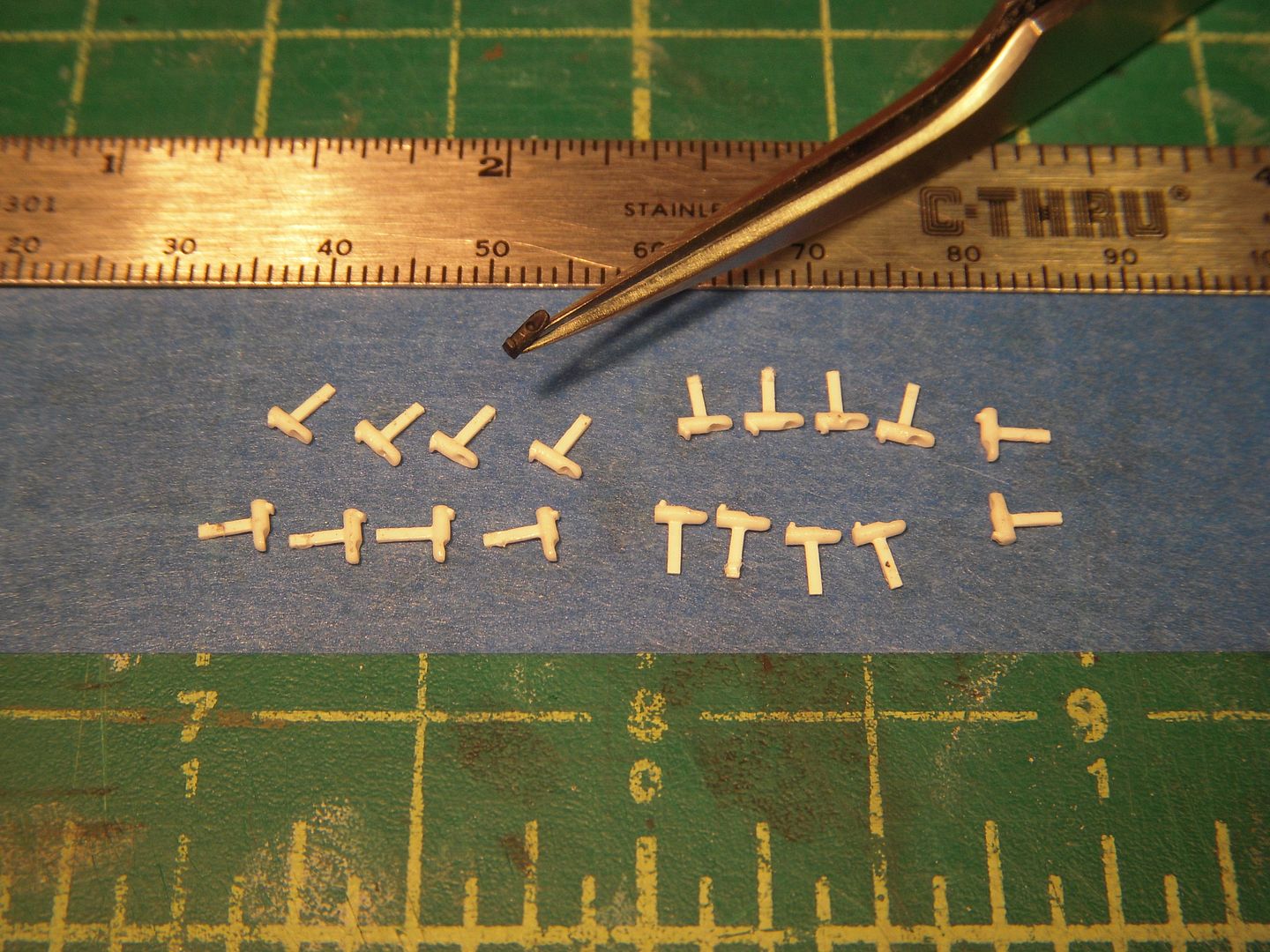

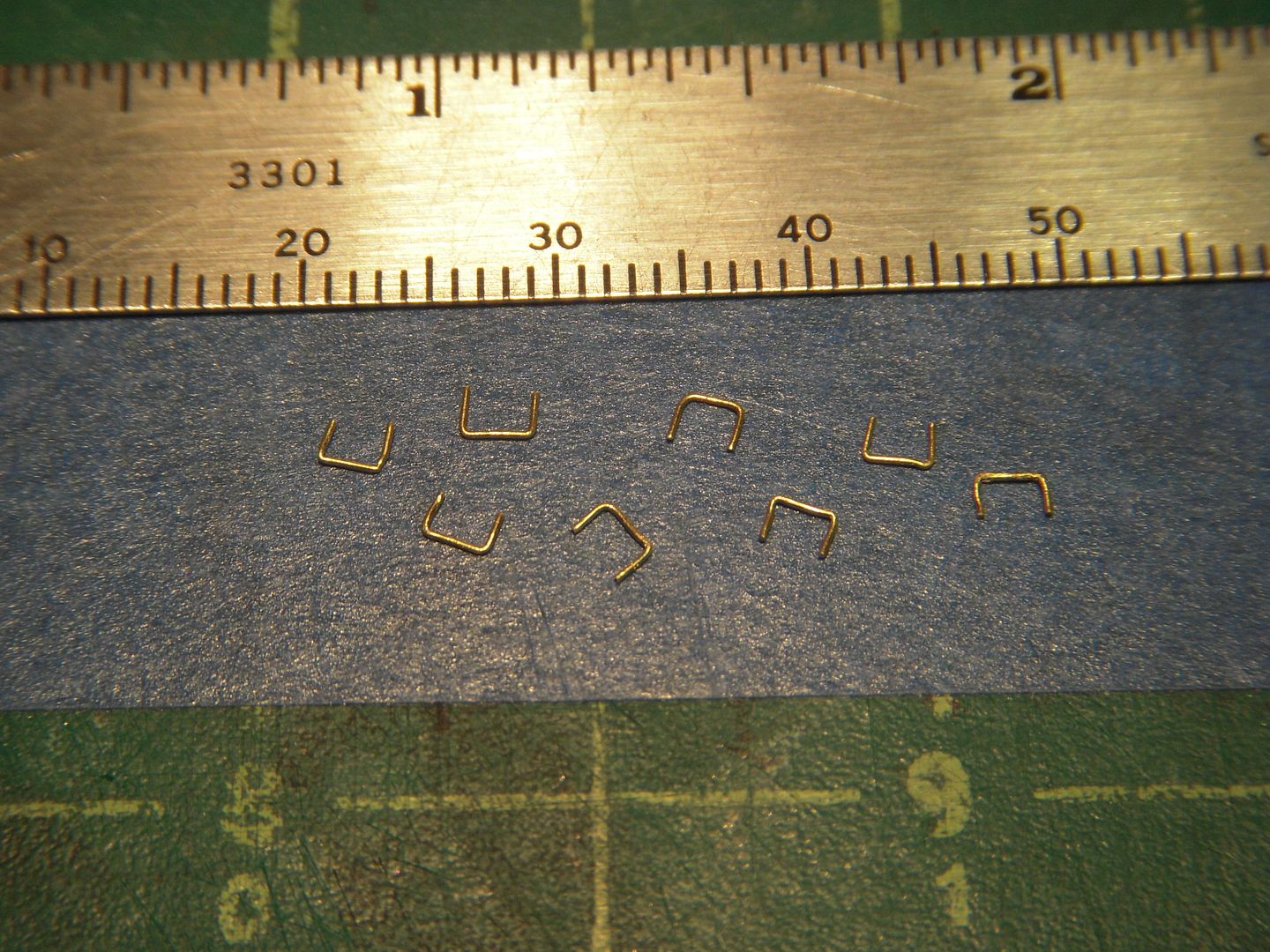

All the parts ready for assembly, with two extra for the carpet monster!

After all the parts are glued together, the carpet monster fodder was not needed!

The finished products look pretty good!

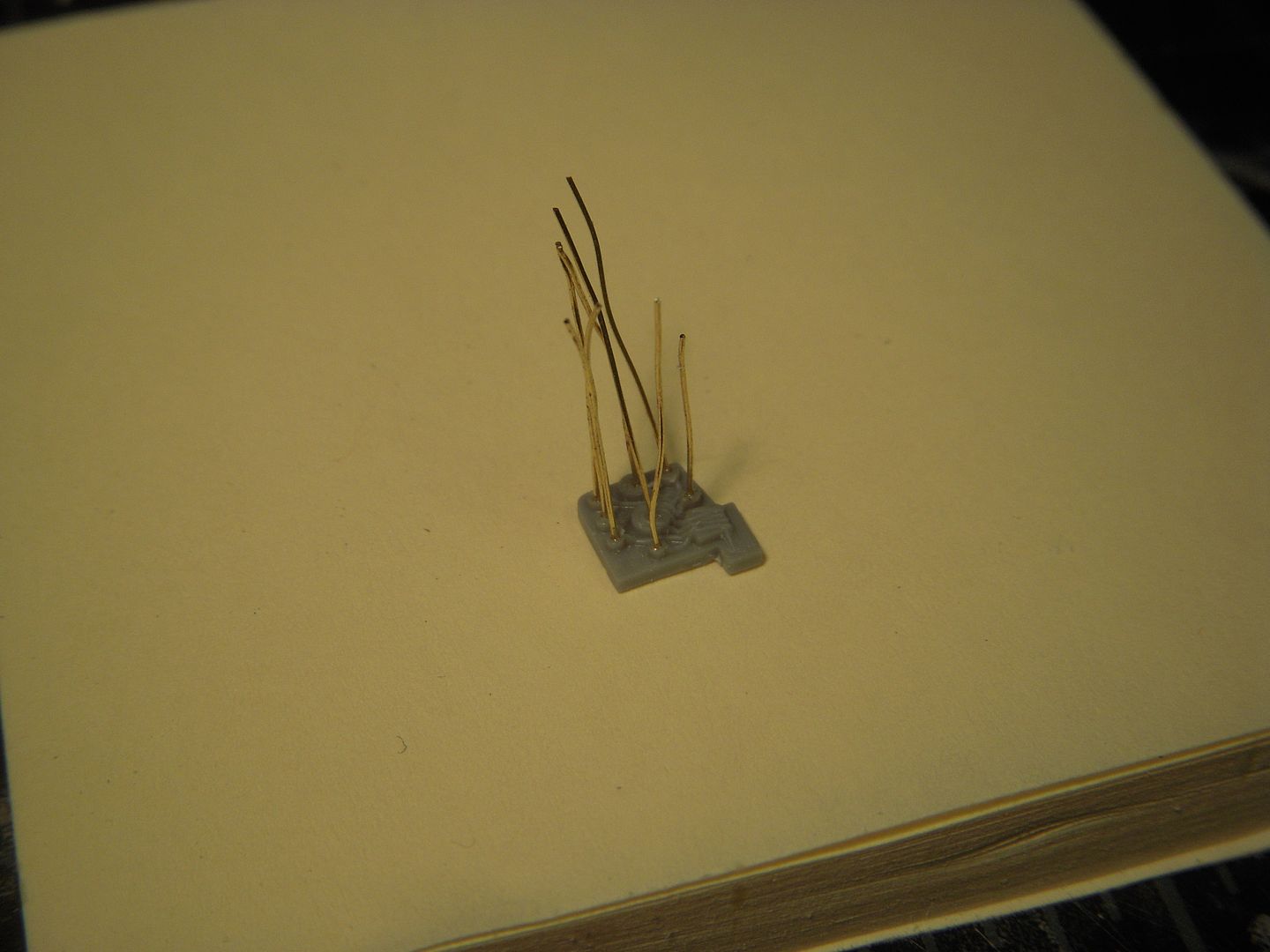

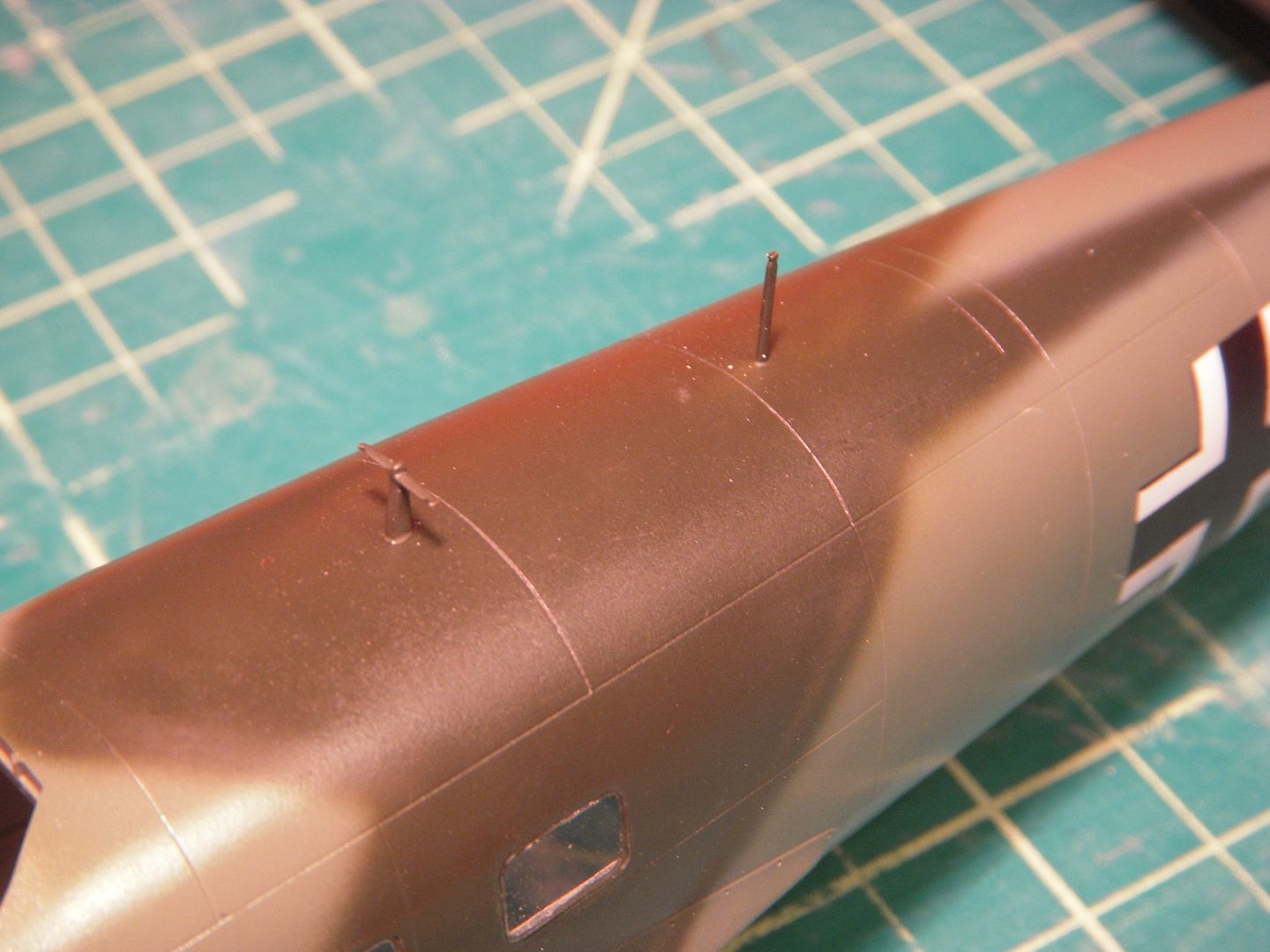

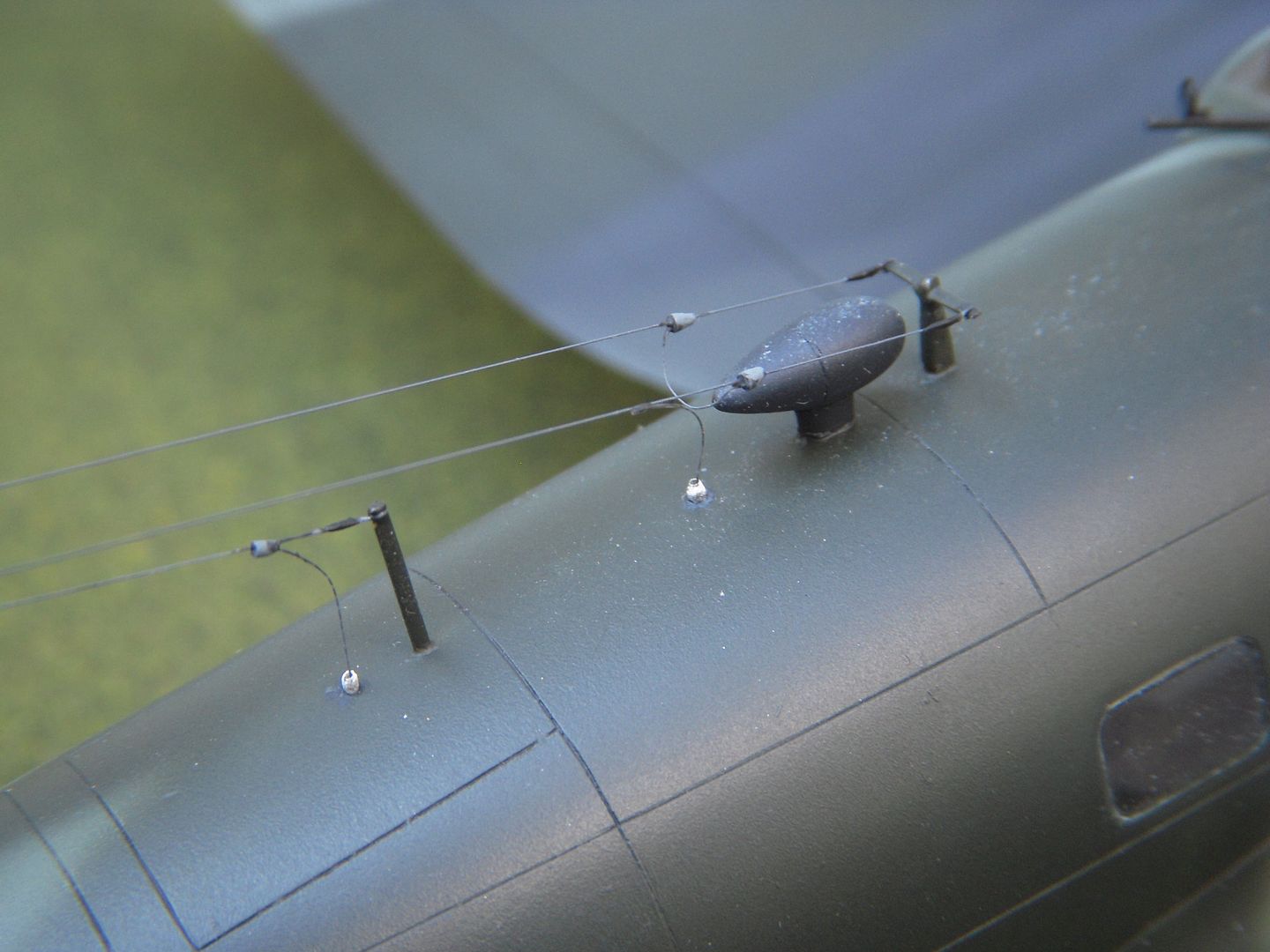

Next the numerous masts for the plethora of antenna was cut and filed from brass sheet and rod. I used brass to ensure enough strength so I wouldn't be knocking them off!.

Turning to the tires 😉 I figured a simple process gluing two halve together and sanding the seam. Of course not! The CASAs in the late 1960s used a tire with a different sidewall shape, being flatter and having circumferential tread with industrial looking scallops. So out with the sandpaper, a round file and my favorite scribing tool. The resulting tires are not perfect but a reasonable representation that is different enough from the WW II Heinkel tires to look correctly "wrong".

That's all for now folks, thanks for watching!

Once again it's been quite some time since the last update. We've had a stretch of nice weather here in the northern Shenandoah valley and after getting some necessary chores done around the house I finally got a chance to fly my biplane, :pilot: so model building was pushed aside for a bit.

A lot of fiddly work was done starting with the exhaust manifolds. The cowlings have a slight taper, while the exhausts, being bolted to the cylinder heads are parallel. A small shim was added to at the front of each exhaust manifold and carefully trimmed to set the proper angle relative to the cowlings. The assemblies were painted, a bit of discoloration added and units epoxied into the shrouds.

The dorsal position being very visible needed a bit of work. Framing was made from styrene strips and epoxied into place. The section of frame at the front was sized to extend about .015” below the clear to provide a mounting surface for the fairing in front of the sliding section. The fairing itself was formed from styrene with careful trimming, bending and test fitting. Some fine brush work to paint the internal frames and masking for the outside is still needed to complete the canopy fabrication.

On the real CASAs, the wheels rode on an axle that sat in a saddle on the end of the shock struts, the axle retained by bolted on caps. On the models, the wheels are slid onto an aluminum tube and the tube ‘axle' epoxied into saddles made by cutting a larger styrene tube in half. The bolts represented by small styrene rod and the caps simply another half of styrene tube. I left the axle aluminum to give a little contrast to the painted fittings, some wash and flat coat will tone the shine down a bit. Brake lines were formed from wire. After the wheels, the gear doors were installed next. The hinges were trimmed to length and the small actuator rods made from stretched sprue. Small recesses were drilled into the gear leg at the appropriate location and pads previously added to the doors. Another actuator rod is yet to be installed between the rear of the gear door and the rear gear struts.

The antenna masts were cleaned up and painted. The small notches filed into the arms will help locate the antenna wires.

And finally (if there's anyone left following this update), a couple of overall pics. I still have to decide on what codes to choose, these supporting actresses wore many costumes for the filming! Thanks for your interest. Eric aka The Yankymodeler

Just time for a quick update. The nose caps, dorsal position glazing and hatches have been painted and are ready for installation. I've opened the dorsal position on my model which necessitated building up the prominent internal framing, why do I do these things to myself?!? :banghead:

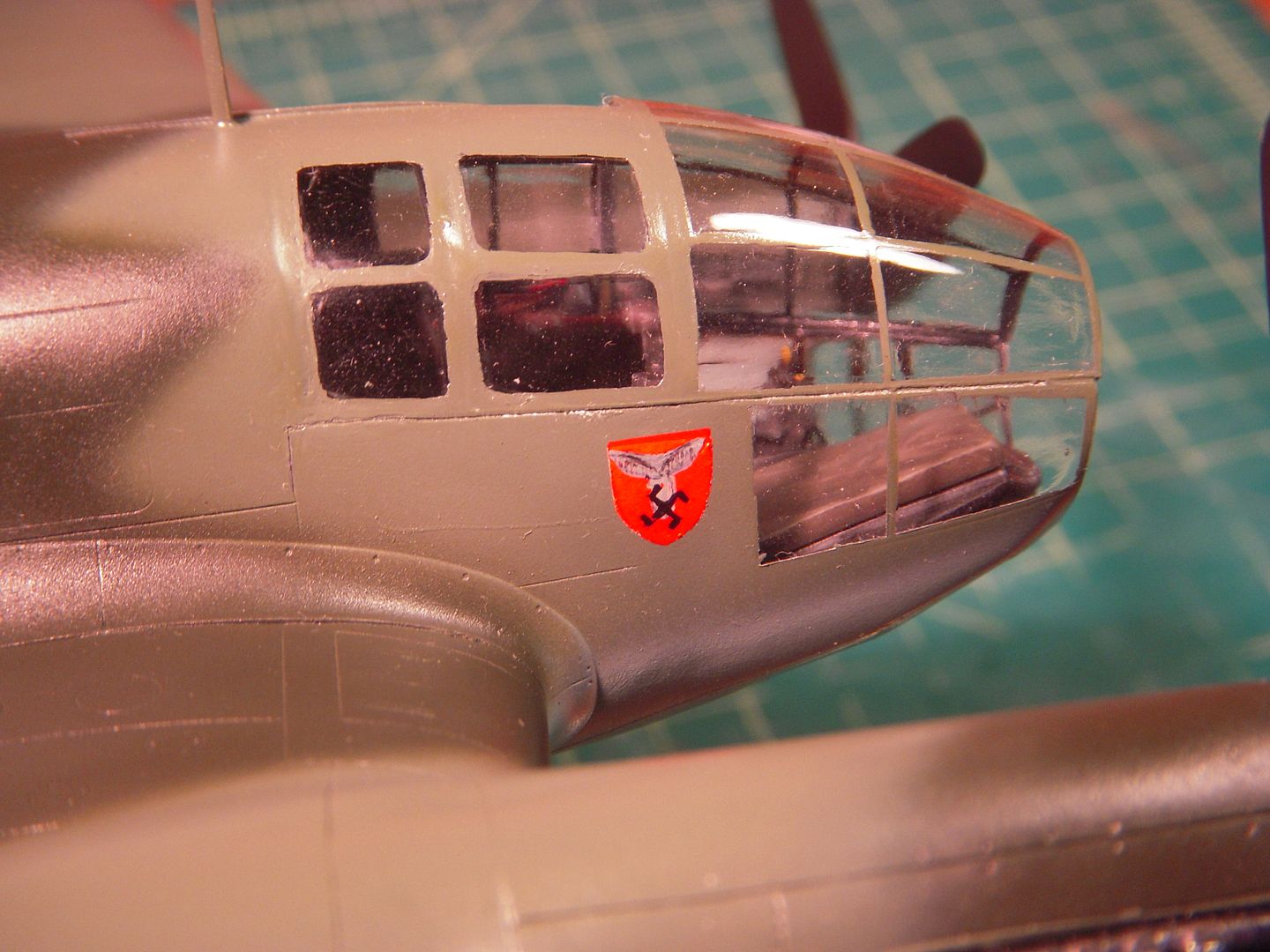

I finally decided on which of the markings worn in their many roles in which to dress these supporting actresses. Of course I then found I had no decals in the stash, nor could I find any appropriate after market! So, out came the masking tape and drafting tools, a set of letters were drawn up and stencils cut. As the squadron codes were stick-on to allow for the many markings changes for filming, I wanted to use decals to give the impression of an appliqué rather than paint the lettering like the German national crosses. A fresh blade and a straight edge turned out some reasonable facsimiles, good thing the originals were not perfect! The squadron badges took a bit of research, but after numerous runs through my DVD copy of "The Battle of Britain", I found enough reference. The badges were painted onto decal sheet, ( it took a number of attempts to get two acceptable of each) given a thin coat of Future and were applied without further problems.

I have never been convinced I had the correct camouflage pattern on the center section of the wings. The CASA's became so filthy behind the engines with exhaust stains, smoke generator residue, fuel spills and general wear it was very difficult to see any pain color at all! During the markings research I found a couple of photo graphs taken from above early in the filming and a few of the CASAs in Spanish service after the movie was complete. Post movie the CASAs appeared to have been repainted in a camouflage scheme that used different colors but the same or very similar pattern. Comparing the early and post photos with what can be seen in the movie has given me a bit more confidence in the revised pattern seen here.

That's all for now, next up will be washes and onto the weathering

Thank you all for your interest in this saga and your kind comments. Into the final stages of the builds and the washes are going well. I'm about to begin putting on exhaust and smoke stains, but I'm stuck on a couple of small but (for me) important details. The images of the marauding 'Heinkels' streaming smoke while hounded by Spitfires and Hurricanes are so iconic to the film that I have to add the smoke generators mounted to the cowlings near the exhausts. The two CASAs that came to England,(G-AWHA/B) were fitted with units on both sides of both engines, above and below the exhausts. The units can be seen in any shots of a 'Heinkel' that is streaming smoke. I have a few low resolution pics taken near or after filming was complete that show empty brackets mounted to the cowls. As the entire area on the aircraft became quite filthy black, it is very difficult to see any details. Incidentally, it is usual to see white smoke from the inboard side of the nacelles, and black from the outboard! I'm having difficulty in finding clear pictures or even a written description. Would anyone be able to assist?

Eric aka The Yankymodeler

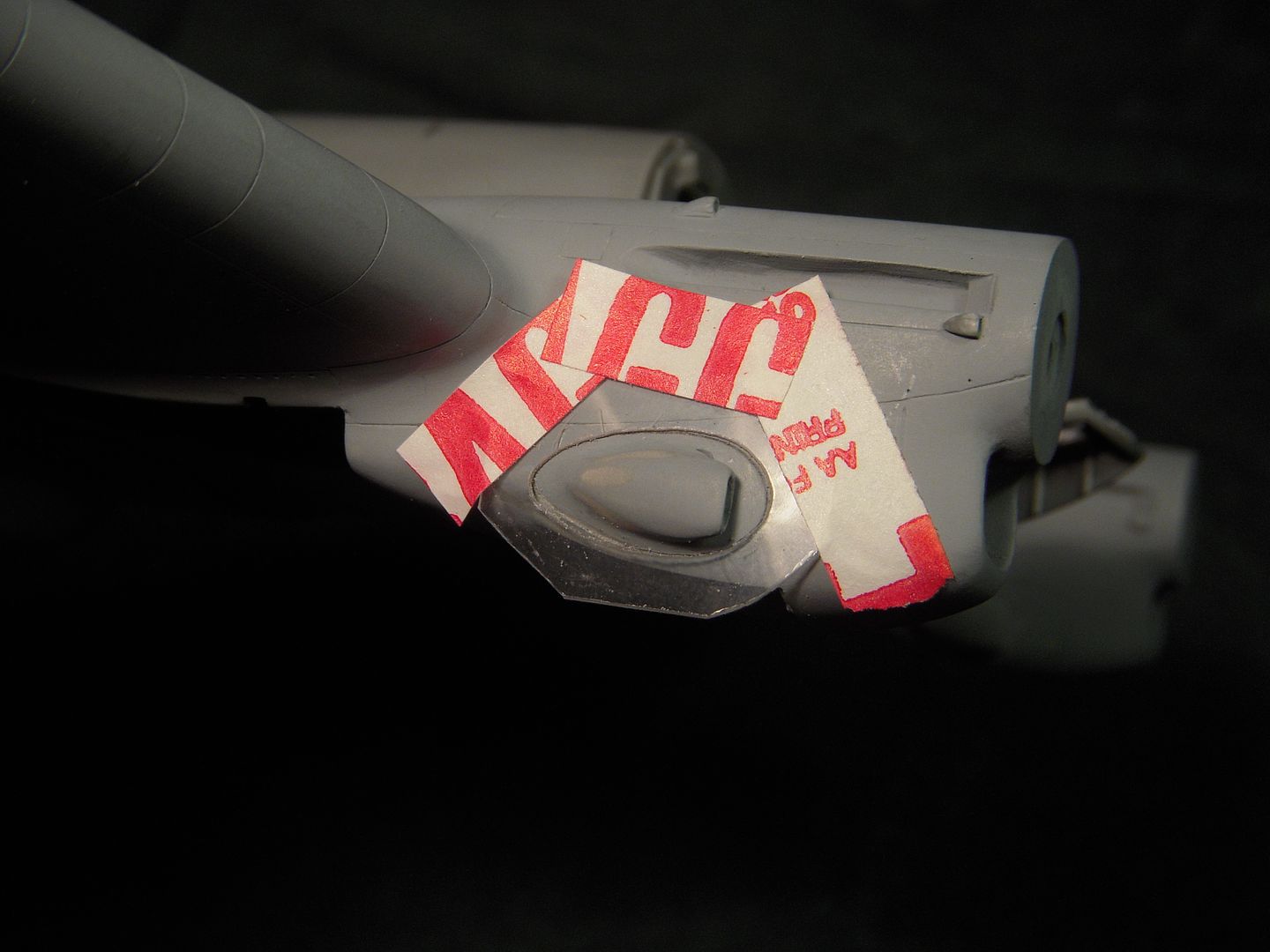

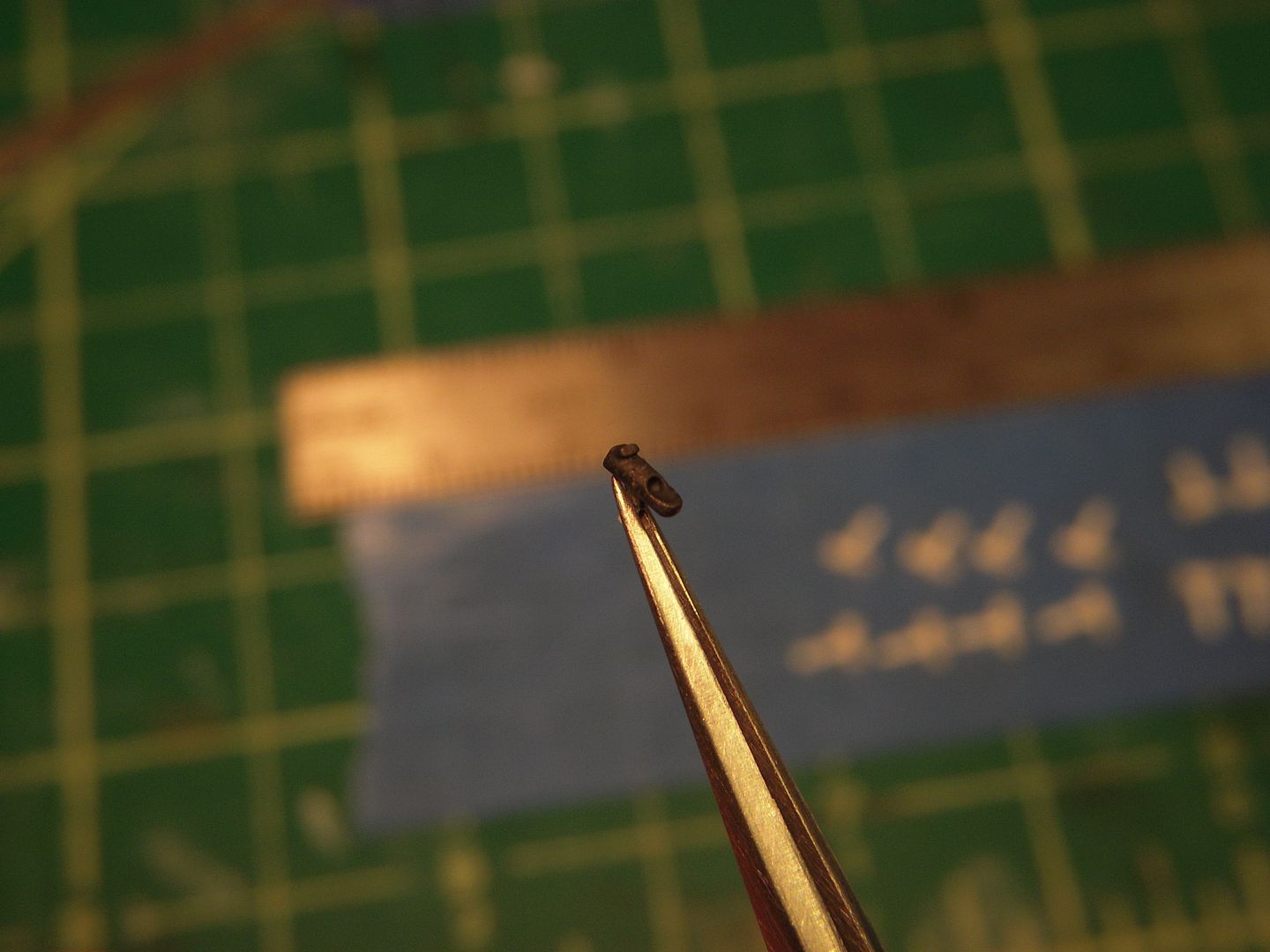

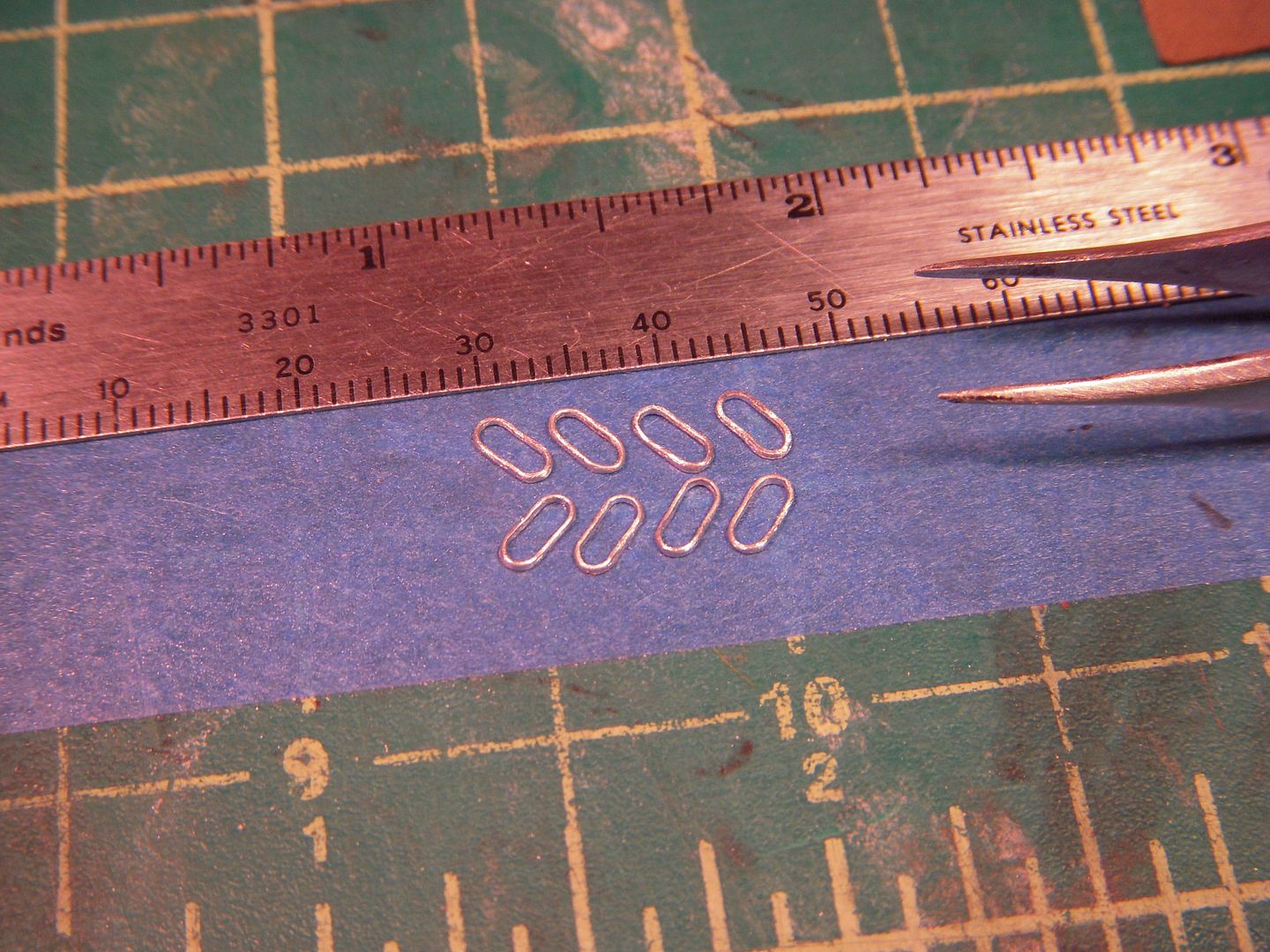

The image of 'Heinkel' bombers trailing copious amounts of smoke and falling out of formation is so iconic to the "Battle of Britain" that I just had to add the smoke generators used to produce the effect to the CASA which will remain in my collection. The other (marked A4+CR) will go to my project instigator friend who prefers the look of the aircraft without the generators. As the generators were mounted and de-mounted according to the need of the particular scene, both configurations are correct for the filming. After much researching and enlarging photographs to the point of graininess, I think I have been able to produce a reasonable facsimile. The CASAs carried 16 (!) mounted above and below, inboard and outboard of both engines and appeared to consist of a tube with large oblong opening in the back and an angled vent near the front. They were mounted on struts that held them away from the cowlings, presumably of protect from heat as close inspection of the movie showed occasional flame visible while making smoke!

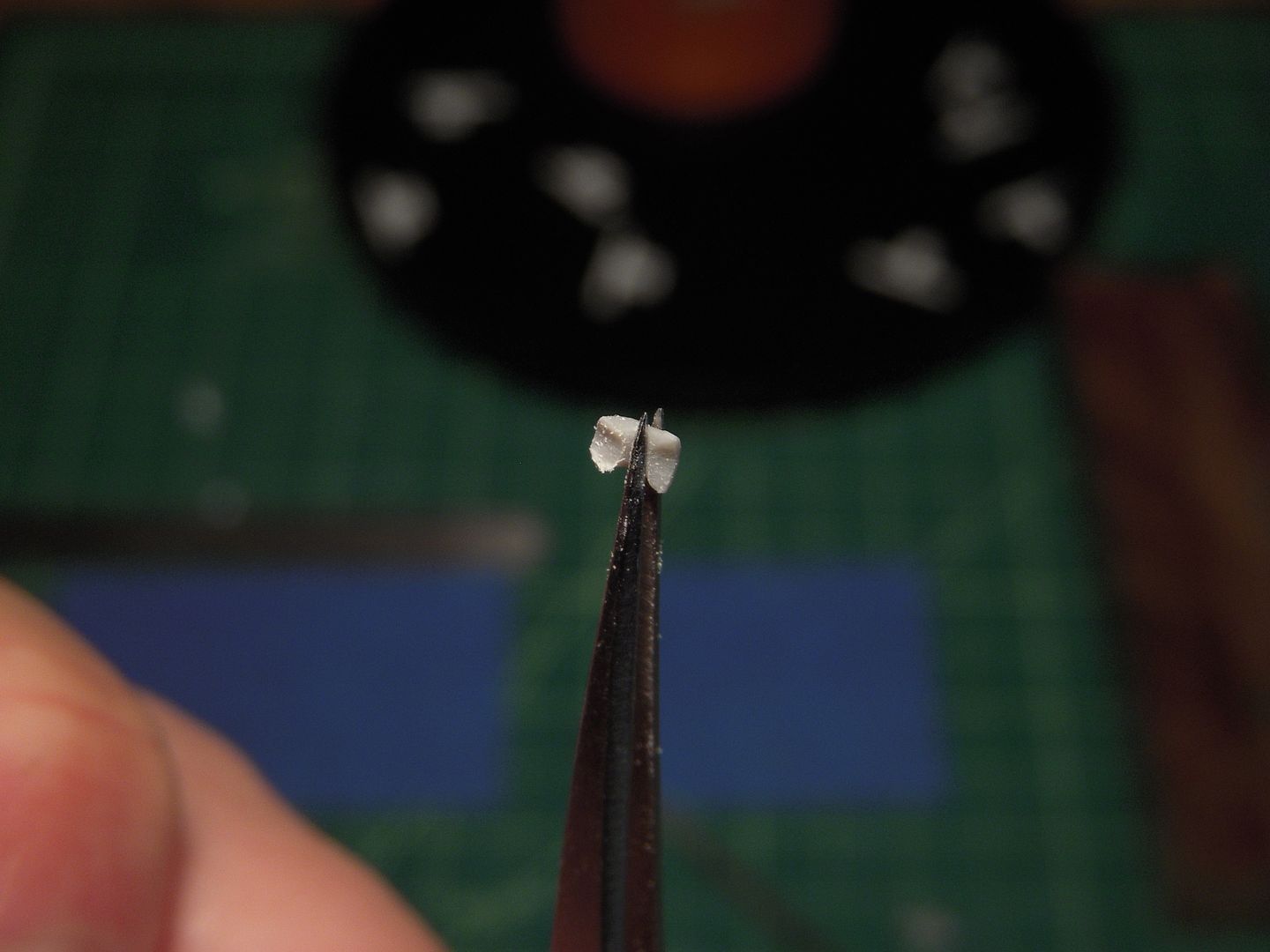

I started with .040" styrene rod and rounded the end. A small dental bit in a motor tool was used to make an oblong hollow along the side. A .028" drill was used to form an impression of the opening of the tube at the front of the hollow. A section 3.5 mm long was then cut from the rod stock and attached to a styrene strut. The vent at the front of the generator was a sliver (too small to measure) of .015" X .030" glued into position. The prototype looked OK so production began. Twenty units were made in case of loss, two being sacrificed to appease the carpet monster.

The units were epoxied into position, alignment proving somewhat difficult; fortunately some misalignment can be seen on the real units!

The paint work on the CASAs can be seen in widely varying condition throughout the film ranging from almost pristine to having so much smoke, exhaust and spillage residue that the underlying colors can't be discerned. A light wash was used on both the top and bottoms of the outer wings, while heavier and darker washes replicated the oil and residue on the inner portions of the wings and lower fuselage.

I find it very difficult to photograph my admittedly subtle weathering; I hope it can be seen.

Radiators were painted dark grey, drybrushed with aluminum and highlighted with black wash. A bit of blue over spray can be seen, this is intentional (really it is!) as thorough masking was not always done for touch-up work.

Next up: a lot of airbrush work to apply exhaust and smoke stains.

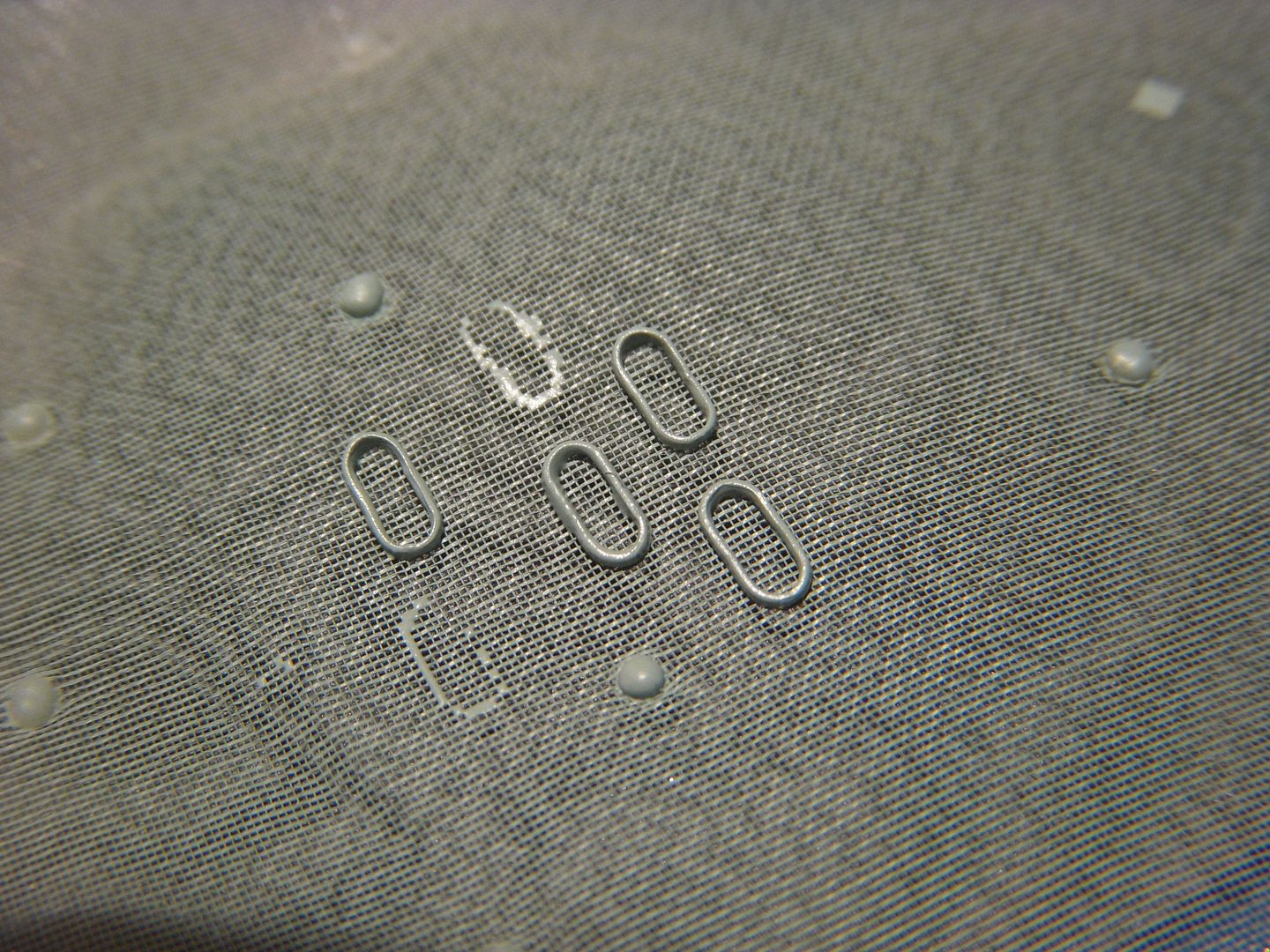

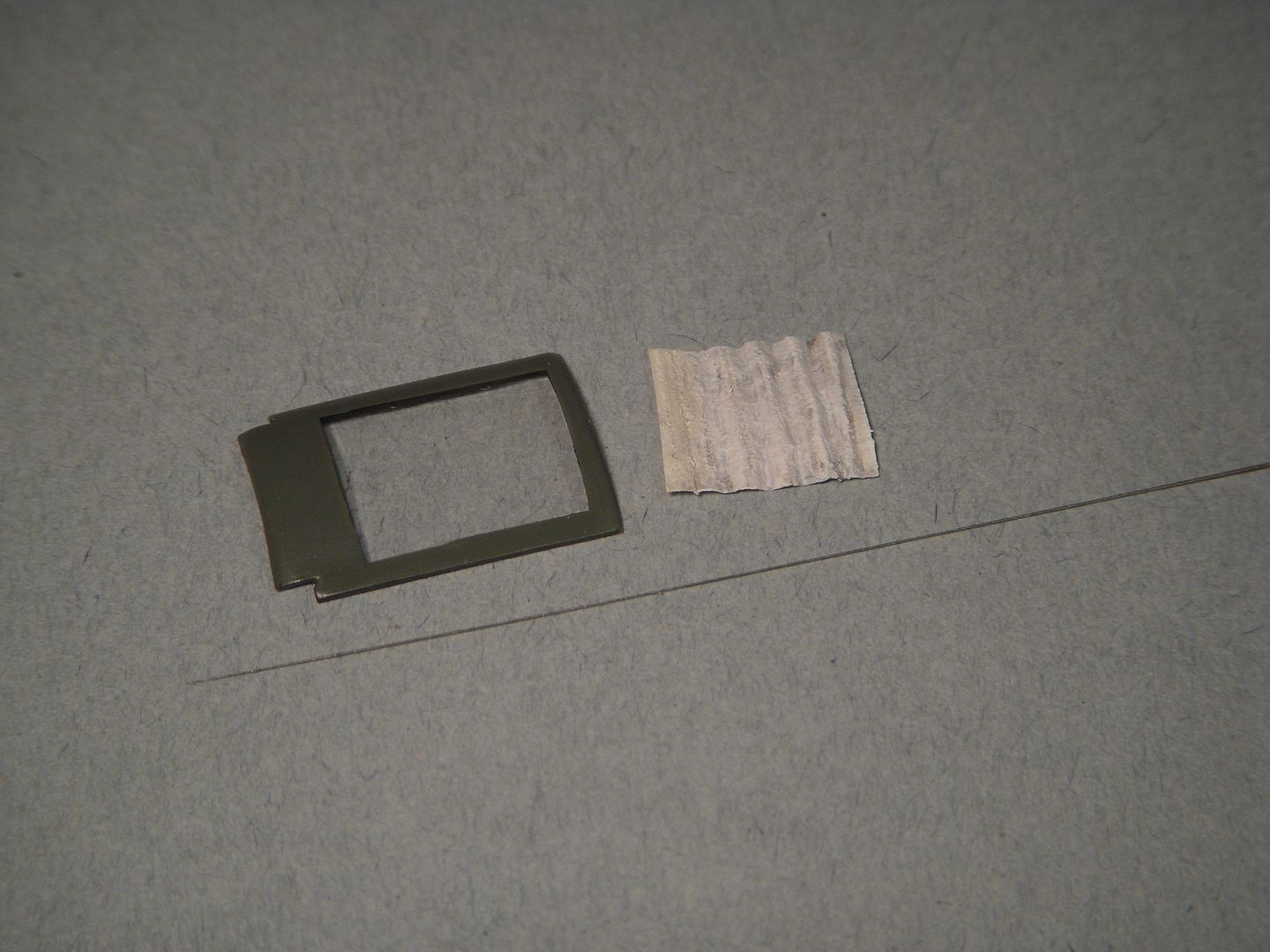

More progress already! (highly unusual for me :rolleyes: ) I have puzzled for some time on one of the last details to be added. The CASAs had in-front of the air intakes on the side of the cowls, a frame that held a fine mesh screen. These screens are carried a few inches ahead of the intake and serve as protection from airframe icing closing off air to the induction system. The idea is that ice will form on the screen and allow air to enter the intake from the side. Some loss of power will result by loss of 'ram' pressure, but the engine will continue to run.

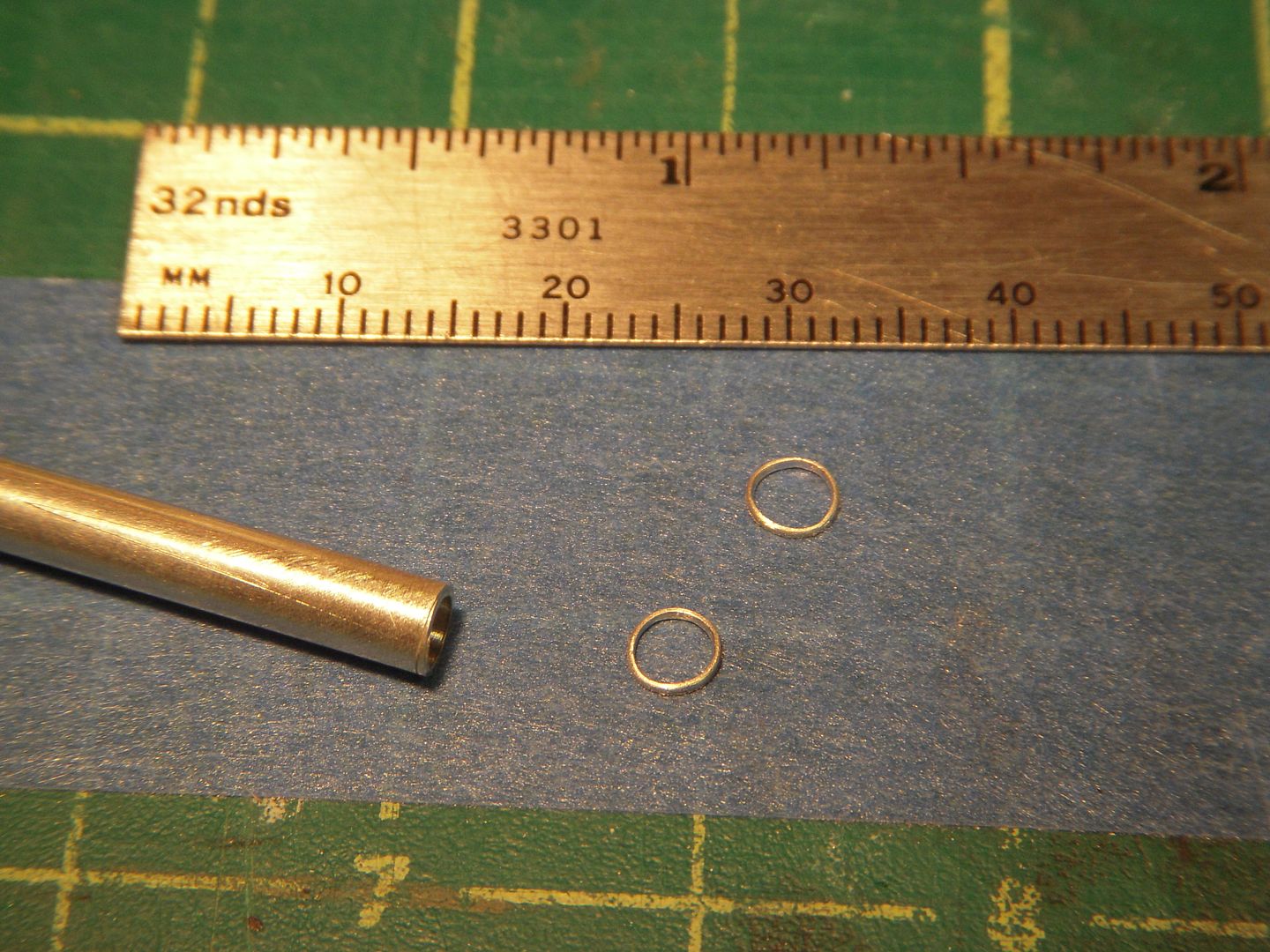

I started by cutting off a thin piece to aluminum tube. The slice was then squashed into an oval shape with tweezers.

The oval was then glued to a piece of fine mesh stockings to simulate the screen. (you don't know what I had to go through to get those off of...err, I mean...from the Misses )

The brackets were made from copper wire, bent around a jig. They were then epoxied to the front of the air intakes. I'll allow the epoxy to cure well before attempting to attach the frame to the brackets.

A couple teaser pics of the weathering process. Smoke and exhaust stains on, the special effects smoke was so thick it even blackened the tails.

I might even have this done for the IPMS Nationals in August!

This should be the last update before completion! :thumbsup:

The anti-icing screens have been attached with a small amount of epoxy and a large amount of patience and gentle positioning! I have to admit to being quite pleased with the results.

Radiator door actuators have been made and glued into position. These will probably never be seen again! :banghead:

The hatch over the pilot's seat carried a sun fabric sunshade that slid on wires on the inside of the hatch. The shade was fabricated from tissue soaked with thinned white glue. gentle folds were formed as the glue dried. The shade was painted with a bit of highlights and shading to bring out a folded look as if the shade was retracted. The wires are stretched sprue glued to the underside of the hatch the shade then added. Small bands of shade color paint on the wire represent loops of fabric used to hang the shade from the wire and allow it to slide open or closed. The hatch/shade assembly was then carefully glued to the rails on the fuselage.

The glider tow hook assembly benefited from some wash and dry-brushed highlights

The airframe was given a coat of flat, then the exhaust and special effects smoke residue refined with the airbrush.

The remaining glazing has been attached to the second CASA, as it's getting late I'll stop for tonight. Tomorrow will be navigation lights, antennas and gun barrels.

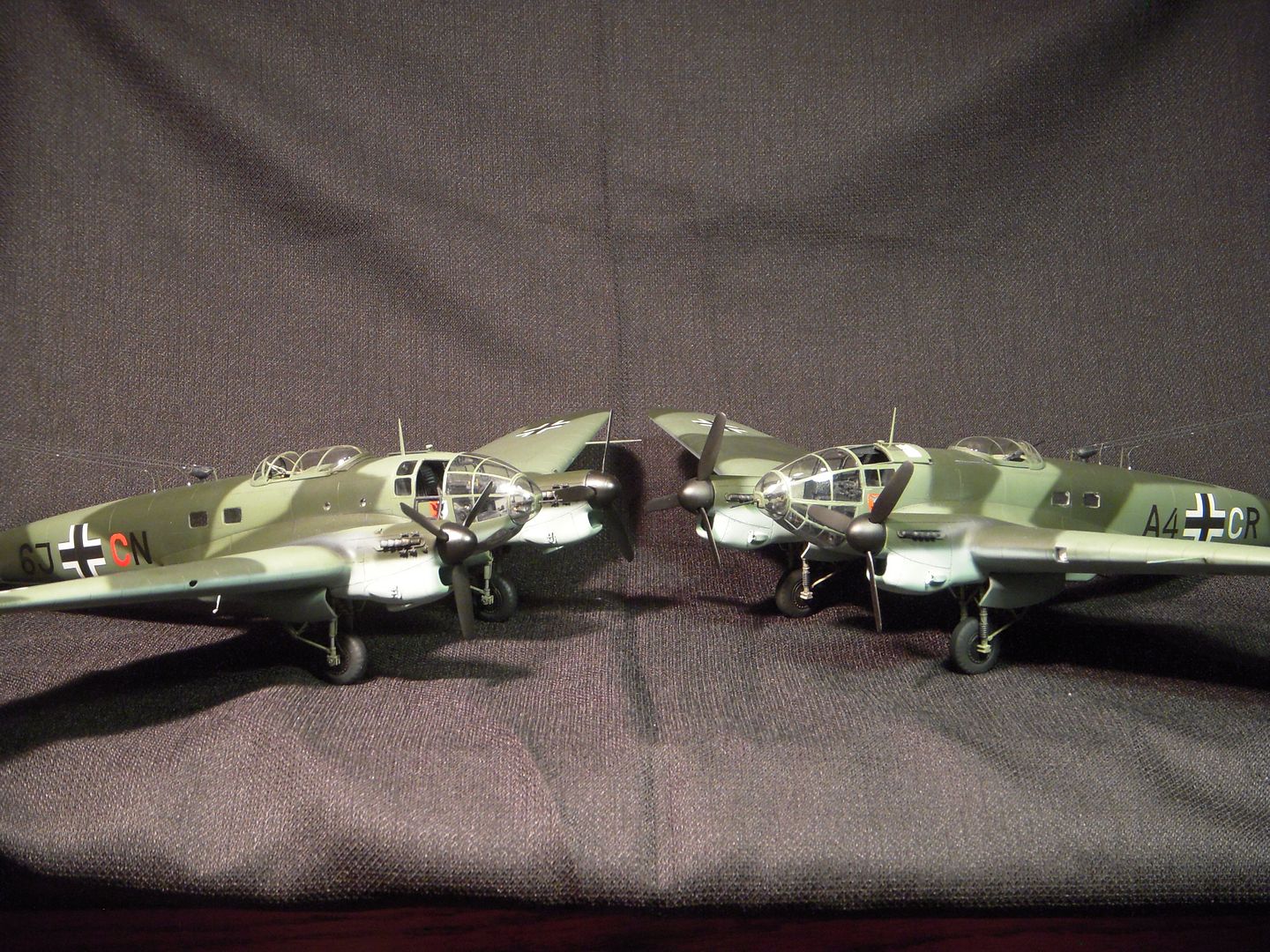

The saga is complete, not only have I run out of pieces to add to the models, but they have gotten very difficult to handle without breaking something! Here for your inspection are models of the two CASAs purchased by Spitfire Productions Ltd. from the Spanish air force in 1968, and flown to England for the filming of the movie 'The Battle of Britain'. Registered G-AWHA and G-AWHB, both aircraft survive today. One model, marked A4+CR, will be delivered to a dear friend I blame for instigating the entire BoB movie star build series. :poke: The other, 6J+CN will reside in my collection. Construction has been amply covered in the WIP thread so here are the finished products

The antenna array with it's plethora of wire, insulators and vibration dampers flapping in the airstream was one of the most memorable images I had of the movie as a child so I spent a bit of time on this detail.

The code letters needed to be changed easily for different scenes, so they were applied with stick-on appliques. On close inspection of photographs, a slight sheen can be seen on the area of the fuselage where the lettering was applied. I simulated this with a thin coat of Future. The letters themselves were cut from decals to provide a bit of thickness verses being painted with stencils.

A couple of shots with the second CASA.

Hi y'all! One last update for all those who followed this drawn out project. Just got back from the IPMS National Convention at Orlando Florida. The entire family had a wonderful time exploring the world of DIsney and my son and I spent 3 days meeting and talking to some great people at the convention. It was hard to believe how many fantastic models were on display, every one a work of art. The CASA was entered into the competition and was awarded first place in the Conversions category! Quite an honor in light of the competition. Congratulations to all participants!

At the MarauderCon contest just outside of Baltimore, as the crowds admired the many impressive models attending the event, a group of aging movie stars was seen gathered together on the collections category table. An enterprising paparazzi photographer was able to capture a few candid pictures as a small group of admirers reminisced of the glory days of aviation films when real aircraft flown by real pilots performed for the cameras.

Note this is the first time I've had the entire collection together. I delivered the fighters to my Project Instigator Friend before the CASAs were built.

That sound you just heard was my jaw hitting the computer desk! What an outstanding presentation that was (is). Your attention to detail throughout the entire process is simply amazing. Your modeling technique(s) are outweighed only by your talent(s). I (we) eagerly await the subsequent builds in the 'wings'.

However, something tells me one of your future projects will most likely be a Tamiya 1/32nd scale P-51 Mustang.

Congratulations on a most impressive posting.

Thank you very much Craig! This post is composed of a number of interim articles. The entire series has proved most satisfying.

Why dont you make the engine conversion and sell them,i would be one of the first in line even though im in the uk.

How did you do the undercarriage doors

Hi,where did you get the RDF FROM

1 attached image. Click to enlarge.

Watched this come together earlier this year, and it's even more amazing to read the whole thing at one time at one place. If that model hadn't won at Orlando, there would be no justice in this universe. What superb work!

Thank Tom, for both the kind comments here and sticking with the drawn out original posting!

This is where modeling meets ART. Fantastic build and congratulations to a well-deserved award. Also, special thanks for sharing the whole stry with so many pictures.

The only suggestion for the future would be splitting such a long material into several pages so that we other mortals can find our way down to the comments section so that we can express our admiration...

Battle of Britain is my favorite aviation movie of all time, despite the inititial criticism it never been surpassed in showing the reality of combat flying. Thinking of the newer efforts such as the recent Red Tails or Flyboys only makes me sad.

Thank you very much for taking the time to comment! I also thank you for the suggestion to split up a long post like this, I will do so if I ever have a long such a long post again.

There is one more cast member to be finished, I have in progress Rolls Royce,s Mk XIV Spitfire which will be finished in the white and turquoise scheme it wore just before joining the film crew for BoB.

In this case, I happen to have a suggestion for you...

http://spitfiresite.com/2009/09/memories-from-the-filming-of-battle-of-britain.html

And let's not forget other "Hollywood" cornball movies like Top Gun, Iron Eagle, Pearl Harbor, Midway, Firefox, Jet Pilot... just to name a few.

I have plans to do some Tora Tora Tora series ( I need to find some 1/48 BT-13s!) and have already started a couple of B-25s from Catch 22!

I found this online today, took my time reading it and looking at the incredible pictures. you are the reason that I join the site. and the detail on this model is like nothing that I have ever seen. I am in the process of building a 1/32 Revell Heinkel He 111, however I could only dream of possessing the skills that you have acquired to be able to create a price of art like you have done with your model. it has to be the best representation I've ever seen. Thank you for taking the time to put all the post throughout this process. It truly is an inspiration for me to go the extra mile on my model.

Kevin,

I am very glad you enjoyed the article, it was a very satisfying project. I have to say that my skills pale in comparison to most, I'm sure you will develop your skills and achieve anything you put your mind to do.

I'll be looking forward very much to seeing you post your project.

Eric aka The Yankymodeler

Eric, WOW! I'm kinda new here & found this wonderful write-up of your great work. Such detail & precision is awesome! Thanks for sharing ... so many years ago.

Sometimes I can only shake my head on wonder at the art work. Every time I labor over details I think are crazy, I see a project like this and realize that what seem monumental issues to me, are minimal attempts by comparison.

The cockpit detailing, an absolute necessity on this aircraft, is superb. Truly one of a kind. My favorite subjects are ones not massed produced and I doubt you'll find this eclectic selection of reel warbirds on anyone else's shelf.

I've got one of these kits I'm building carrying a magnetically attached Reichenberg R-4. However, like the monogram C-47, there seems to be a lot of problems with fit, especially around the canopy, that put me off. After looking at various examples of this model on this website, I wonder if I'm up to the complex paint scheme However, I have almost completed the R-4. In fact it was researching this aircraft that brought me to iModeler from Pinterest.

I once got a ride in one of these CASAs provided by a competitor. When he wasn't flying an Air Tractor spraying crops, he was chief of maintenance for the Confederate Air Force. At the time, it still was based in Harlingen and from time to time he would fly the birds for various maintenance checks.

He invited me to go along on one of these check rides as a passenger. What a strange and rare ride in a Spanish/German bomber over the Texas coast some fourteen years after seeing the movie. A once in a lifetime moment that will never happen again except in memory as this was the only remaining airworthy CASA-111 before being destroyed in a fatal crash landing.

As I remember, the interior was still black, while the nose panels seemed more angular in appearance than the original German version. The twin Merilns had a very different exhaust note from the radials to which I was accustomed.

There's a guy in Texas who was paid for his role in the movie with a number of these aircraft after the movie was completed. He had them sitting un-restored in a hanger until selling them at auction three years ago. http://www.dailymail.co.uk/news/article-2846976/Stars-skies-Collection-six-Messerschmitts-appeared-1969-film-Battle-Britain-sold-4million-sitting-hanger-decades.html.

When I look at those sad examples and think of the work involved, I'm glad I can pick mine up and put them back on a shelf.

Hi,is there an actual 1/48 casa conversion kit out there off the shelf,if there is can anyone give the details please.thankyou.

Hello David, Unfortunately I know of no commercially produced conversion kit. The components can be fairly easily gathered though, the main major part is finding a Merlin engine. That can be sourced from a kit or an aftermarket detail manufacturer. As the article outlines, the rest of the conversion is relatively straightforward. Good luck!

Eric aka The Yankymodeler

Thankyou for your reply im not a great modiller i just do it for myself and dont have the skill and the tools to achieve such a magnificent model.i do have the messerschmitt bf109 1/32 hispano buchon conversion kit and on ebay they have a heinkel111 conversion 1/72.but thankyou for response.

Hi Eric

This is a fantastic Blog. I am currenly doung a CASA in 1/32. Are you interessted in sharing some details in the cockpit with me?