Review: Miniart 1/35 T-54B Early Production – Build Review, Part 3

This article is part of a series:

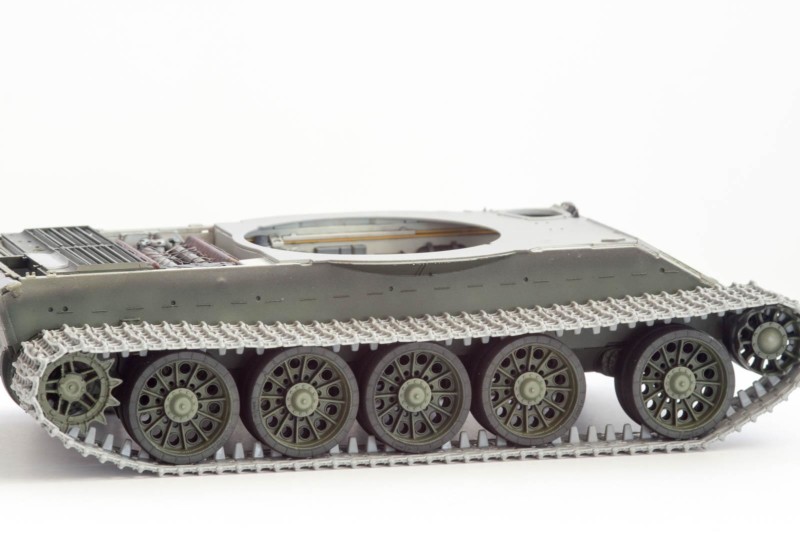

Lower Hull and Running Gear

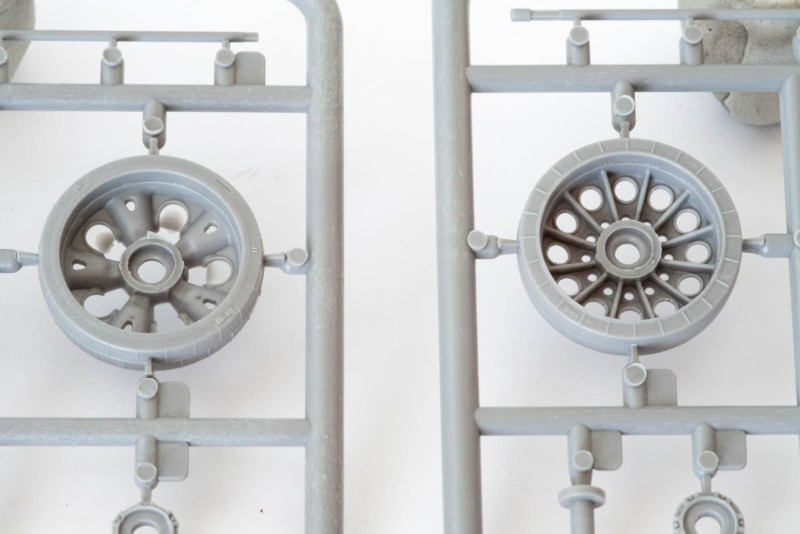

As with the rest of this kit, this is a very intricate assembly with lots of parts. What you end up with, however, is an articulating suspension, which makes it ideal for dioramas. As mentioned before, you have the choice between two different types of road wheels – the ones with teardrop shaped lightening holes show quite some flash which needs to removed carefully, and the pattern on their rubber rings makes removal of the sprue attachment points a bit tricky.

I decided to use the spoked wheels, gluing each pair together before removing the center seams – that way you only have to handle half the amount of parts

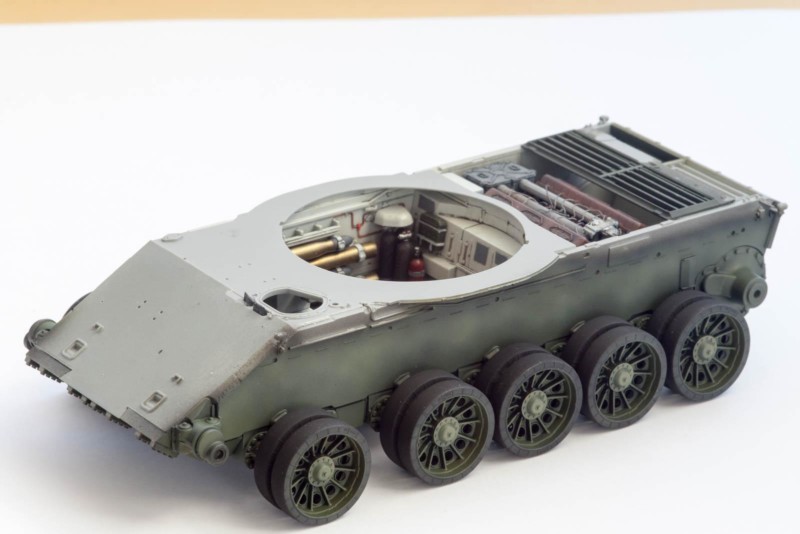

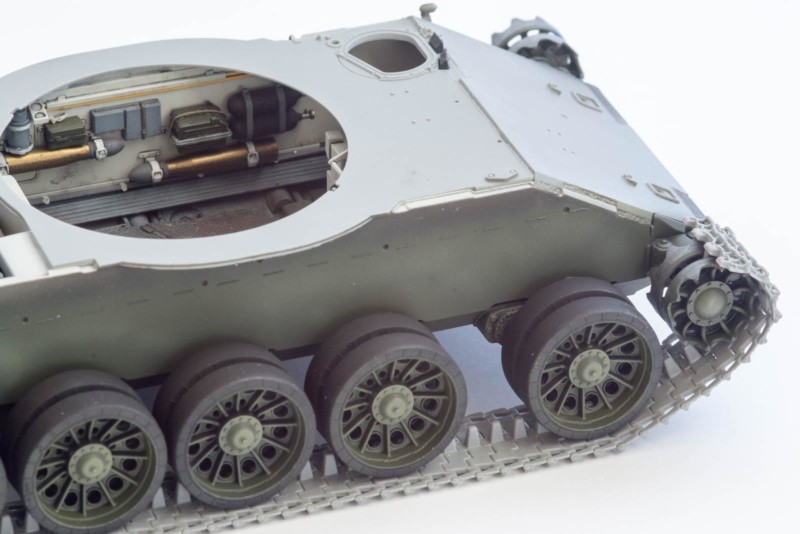

Attaching the road wheels to the swing arms is made difficult by short stub axles and a rather loose fit – I glued the wheels to the swing arms and then basically “clamped” the whole lower hull between two heavy books to assure the wheels would all sit true and in alignment. I decided to paint the lower hull and the running gear before assembling it, making it easier to reach into all the corners.

Before proceeding further, you will have to tackle the track. The whole articulating suspension is somewhat let down by the fact you need to glue the track links together – the tracks are definitely not workable. So if you want to show the tank in a diorama on rough ground, you will first have to set the running gear onto the ground, glue the swing arms into position, and then assemble the track to fit the running gear.

As this one will be sitting on even ground, my life was made a bit easier. I started by assembling the bottom run (40 links per side), followed by 12 links each for the bends around the drive sprocket and the idler wheel. Gluing the links together using Tamiya Extra Thin, I waited for 10 minutes and was then able to carefully bend these runs around their corresponding wheels.

The remaining 26 links where assembled in the same fashion, making sure to create the typical gentle sag, touching the middle road wheel.

After everything had dried I was able to remove the track parts. It is important to have the drive sprockets and idler wheels not glued to the hull, making it way easier to remove and reinstall the tracks.

The tracks where painted with a base of Tamiya XF-1 Flat Black, followed by a wash with dark brown pigments mixed with pigment fixer. The ribs which will get in contact with the ground received a treatment with a soft pencil and a graphite stick.

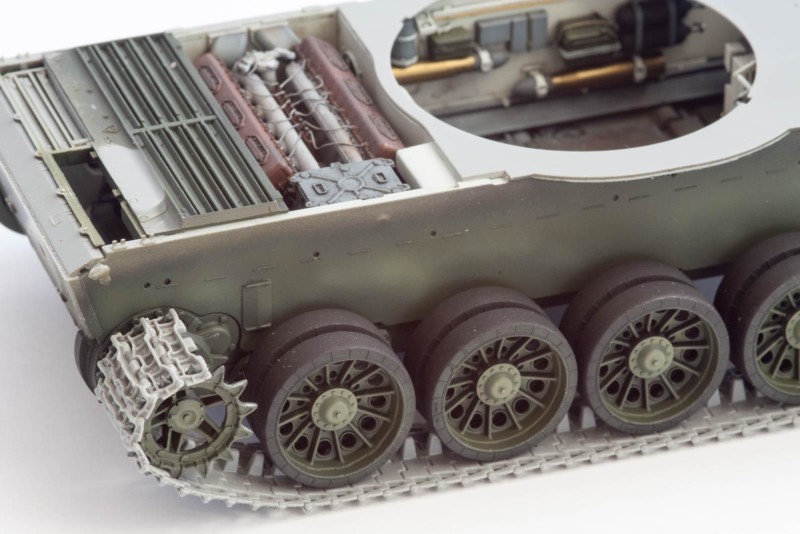

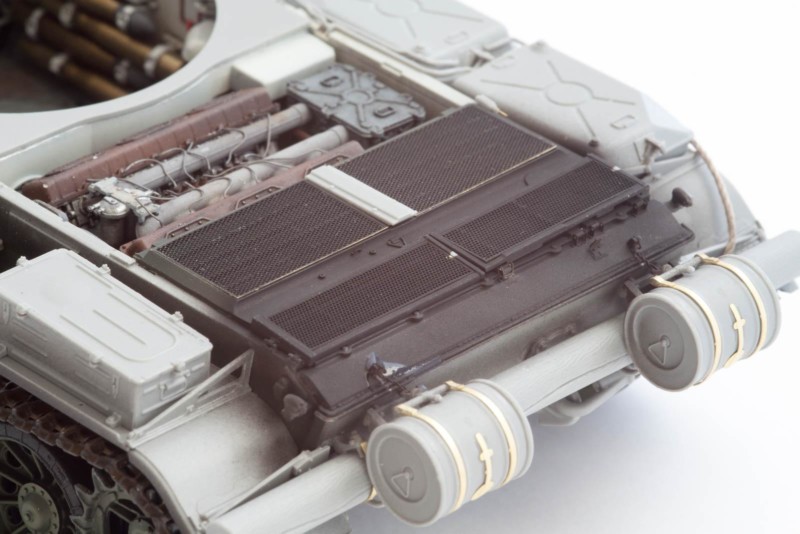

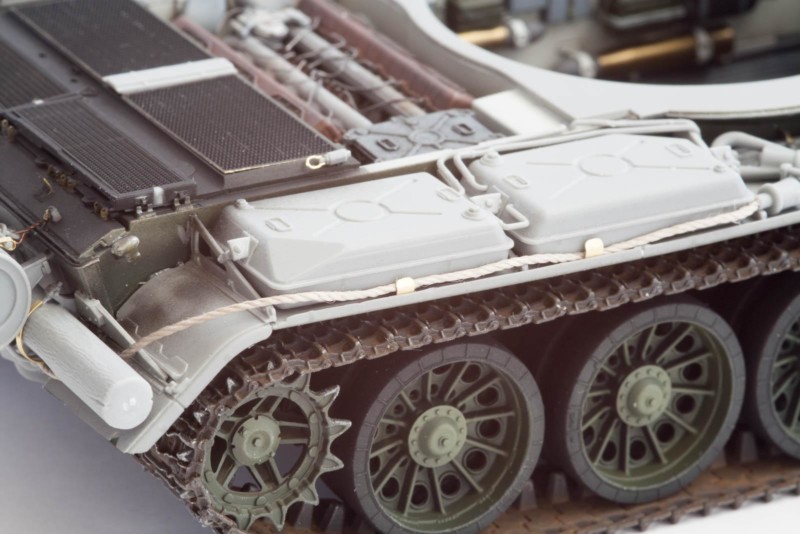

The Upper Hull

For the most part this is rather straightforward; just make sure not to overlook some of the tiny parts, as the instructions are a bit busy. Again, one of the very thin parts broke into multiple pieces when removing it from the sprue, so I had to replace it with lead wire.

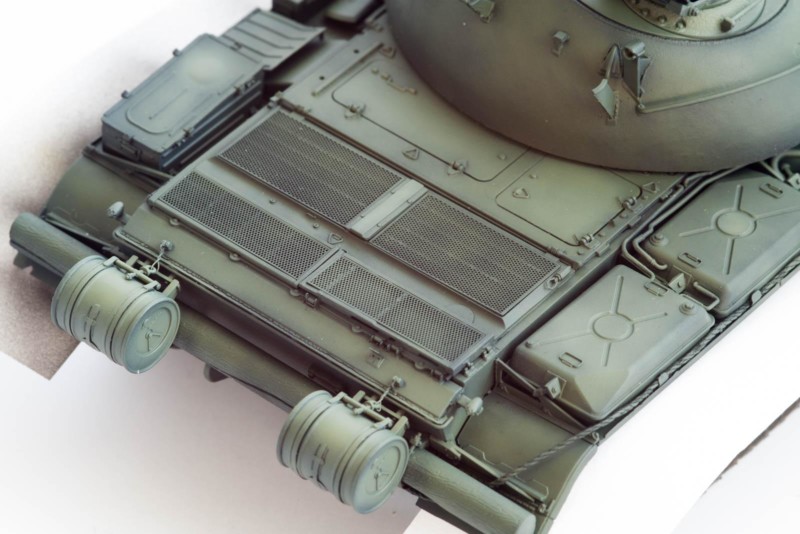

I decided to paint the engine covers separate from the PE grilles, making sure to get paint into all the crevices.

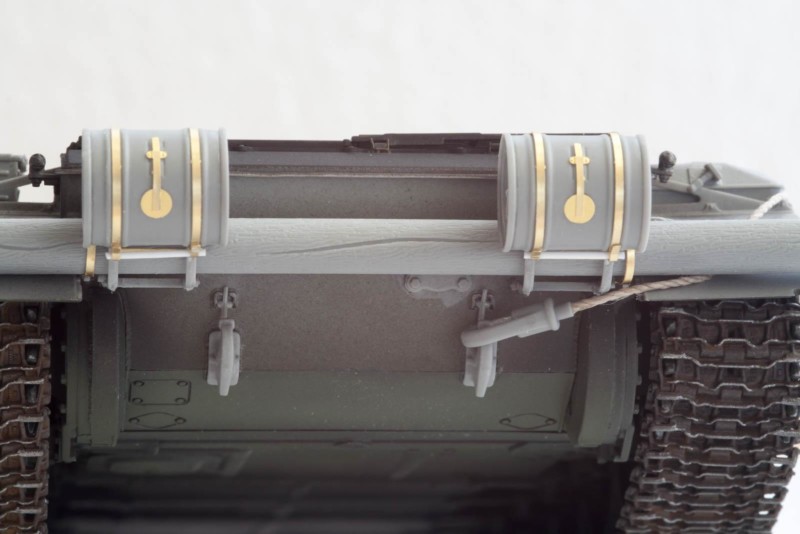

The back of the hull sports two fuel drums and the ubiquitous unditching log. Construction involves some PE and narrow tolerances for correct placement. You will definitely have to fiddle around here, so take your time! Again, I had to replace broken parts with styrene rod.

The light guards and lamps assembly consists of ten parts, making for a well detailed but delicate affair. The blackout driving light was attached right away, the standard lamp was left off until after painting to make installing the clear lens easier.

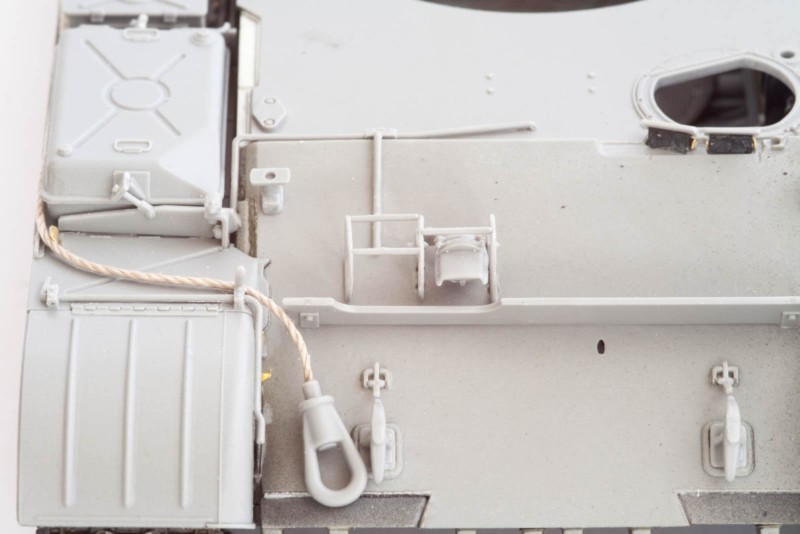

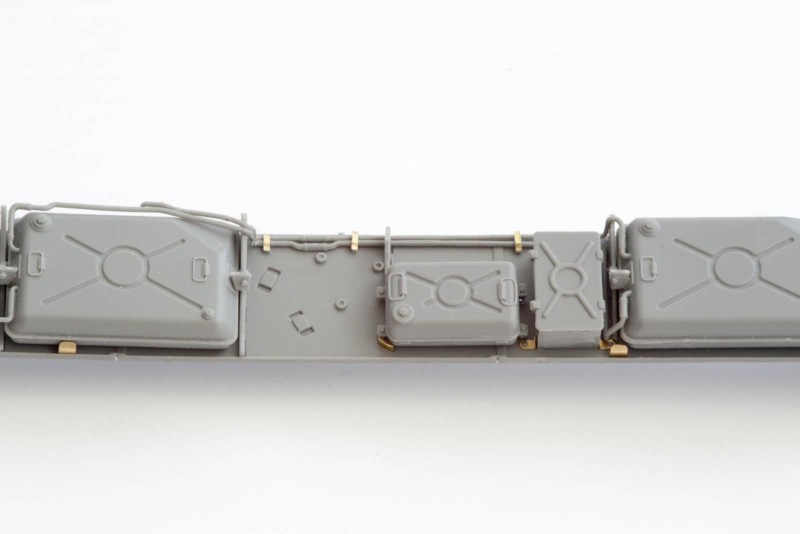

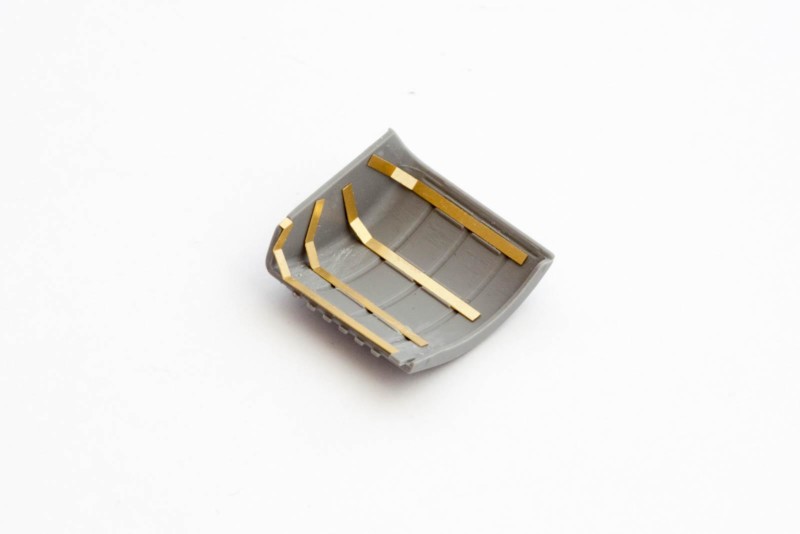

The Fenders

Now this is a busy assembly. You will need to attach a multitude of plastic and PE parts here, some of them tiny, and, again, the fuel lines are prone to breakage. I somehow managed not to damage them, but it was close…

The undersides of the front fenders have PE supports, and their exact placement is not clear from the instructions. They should look like this once attached:

Attaching the fenders to the hull takes some patience, as it is not easy to see the mounting holes. You might want to work with a slower drying cement here, making it possible to tweak their position a bit.

The tow cables are not usable out of the box. They come as straight plastic parts, and I guess Miniart expects you to bend them to shape. Yeah, doesn't work, apart from that one of them was already broken when I opened the box. I replaced the cables with some thin rope, just keeping the kit's eyelets.

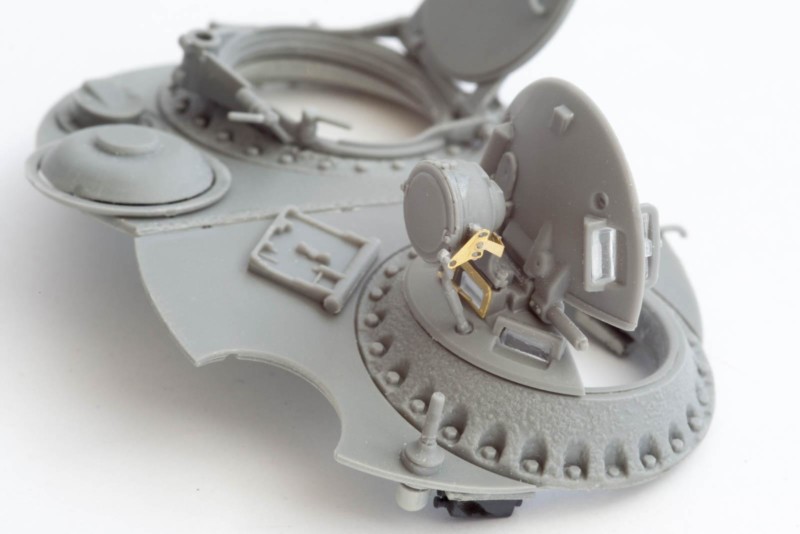

The Turret

When working on the interior, I got the slight impression that the instructions for the hull and the turret were designed by two different people. Where the hull instructions were logical and without issues, the turret section was convoluted, with wrong part numbers and flawed drawings. And the same pattern repeats itself on the outside. You really have to be careful not to miss any part call-outs, as they are sometimes almost hidden in the drawings. And again, some part numbers are just wrong.

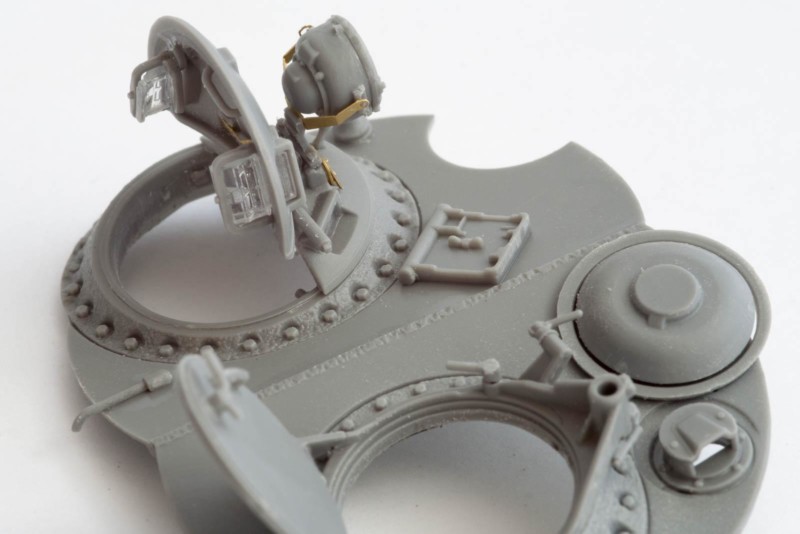

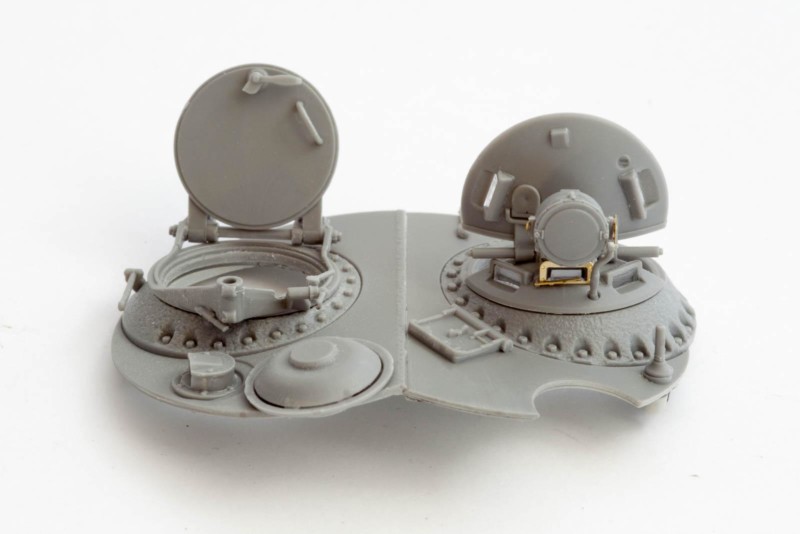

Detail, on the other hand, is again fantastic. The commanders hatch consists of 27 parts, including clear parts for the periscopes and a delicate IR search light. Care has to be taken when assembling this one, as the attachment points between the light and its PE bracket are very small.

The loaders hatch is a much simpler design, but again everything is there and well detailed.

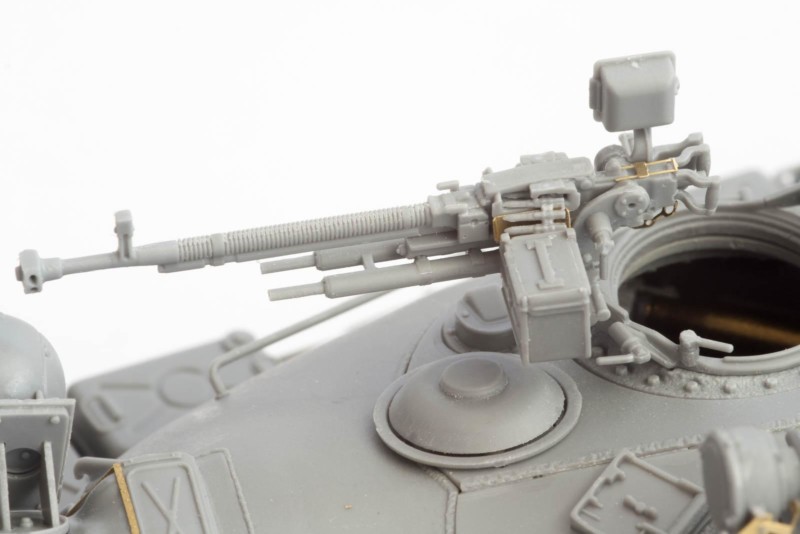

The most involved part of the turret is the 12.7mm machine gun. And especially with this part, the instructions aren't of much help, leaving you to guess the correct location of some of the PE parts. I think I got it right in the end, but I am sure someone will prove otherwise…

Assembling the gun and mantlet is easy. The one-piece barrel is slide-molded and comes with a hollow muzzle, but there are some tiny sink marks around the sprue attachment points. I filled these with liquid styrene and carefully sanded everything to maintain a proper round cross section.

Finally, the back of the turret holds a big tarp. Miniart provides you with a plastic part for that, but I think you will be better off creating your own from Miliput or, as I did, tissue paper and white glue. The kit part shows acceptable detail on the front, but is hollow at the back, and the sides are not detailed due to molding restrictions.

Miniart wants you to attach the tarp to the turret using PE straps glued to tiny PE loops. Though I am sure this would make for a very realistic look, I am pretty sure I would go nuts in the process. As the PE loops will hardly be seen once the tarp is in place, I would suggest leaving them out and attaching the tarp with its straps directly to the turret.

Painting

Cold war Soviet armor seems to loosely follow Henry Ford's rule – you can have it in any color, as long as it's green. However, to make life more interesting, I decided to go with the winter scheme depicted on the box art.

The whole vehicle was given a base of Tamiya Flat Black, followed by a patchy coat of Vallejo Russian Green. Some details and hatches were picked out with a lightened Russian Green.

The decals were applied directly to this color, no gloss coating there. Vallejo Airbrush colors have a satin finish anyway, and the kit's decals are very good. Using a mild setting solution, they behaved flawlessly.

After I brush painted the canvas mantlet, it was time to break out the hairspray. Using the cheapest one I could find, the whole tank was given two coats straight out of the can.

Hairspray dries almost immediately, so after ten minutes I started applying the white camo pattern. I used Tamiya XF-2 Flat White thinned with water. This combination is supposed to make chipping easier, as the white paint will not be as tough once dried. The downside to this mix is a more temperamental behavior out of the airbrush, with paint drying on the needle. Next time I might add some flow improver to the mix.

Chipping the white paint is a fun task, best accomplished while listening to your favourite music (or a lecture on tank development during WWII, in my case). Get some tap water, old brushes of various sizes, and a toothpick, and off you go.

Weathering

As this T-54 will end up in a diorama, I decided not to weather the running gear at this stage, so apart from a brown wash it is pretty bare. The upper hull and the turret, however, got a treatment of oils and Ammo by Mig Washes in various tones.

I started by applying filters in brown and green to tone down the contrast between the base color and the white wash. Next, a range of oil paints was used to create the worn effects. My goal was to achieve depth and visual interest by applying multiple layers of streaking, pin washes, and splatter effects.

Conclusion. At Last.

I honestly do not know where to start here. I already did plenty of talking about the incredible detail this kit provides. The instructions could use a bit of proof reading, and some parts might already be broken when you open the box. But if this not complaining on a high level, I don't know what is.

Is this kit for you? I think the answer is simple. If you are interested in cold war armor, enjoy intricate detail, and always wanted to know what is going on inside a tank, then yes. However, if you decide to build this kit, be prepared for long hours at the bench.

I got burnt out with armor builds a while ago, and this kit brought the joy of doing armor back. And to me, this is the best verdict any kit can get.

P.S.: Miniart's customer service is nothing to sneeze at. I had two small parts missing from the box, and after contacting them they sent complete replacement sprues free of charge – within four days from the Ukraine to Austria. Well done!

Congrats on this build, very nicely weathered as well!

My goodness...THAT turned out beautifully - one of the best I've seen. And your build review was extremely well written as well (along with striking photographs). I have a feeling we'll be seeing this one again in a couple of weeks. Very nicely done, my friend!

Craig, I agree. Beautiful piece of work and a great read!

Articles like this are a credit to the site, truly. Great explanations, well-documented with excellent photography, and extremely skilled modeling resulting in a real work of art. Stellar. Kudos to you.

I've really enjoyed all three articles, Boris, thank you very much for sharing this build with us. Now, where's that diorama?

Very well detailed and documented review and build process. Excellent work! look forward to more from you.. Great stuff!

All articles very informative, Boris. And the result looks great. I think Miniart is one of the best armour kit manufacturers out there. My only proviso with them is that their CAD stuff is a little ‘aspirational’ compared to the kit parts themselves sometimes (easier to draw it than to build it). I’ve built four or five of their kits and all had their little foibles but all turned out well. Glad you got your armour mojo back!

A strong article with some solid modeling and painting= Model of the Month. This article/how to book is in depth and informative. My only niggle is with the white back round. The "Winter" camo on the tank seems to start to blend in with the white back round. Maybe a charcoal gray back round to help focus the eye on the eye candy next time. All in all a professional presentation. Two thumbs up Boris.

That is a really good article mate! I love the build as well, spot on. The hairspray effect is really convincing.

4 years latter, I stumbled upon this lesson about building and painting armour. One of the best tanks I’ve seen ever