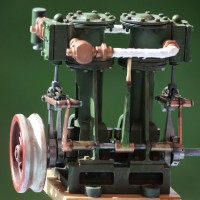

steam engine

result of my first experience with a 3D printer.

It still has some failures due to lack of experience with the printing process, but I am very happy with all the workflow and the freedom it gives you to be able to create almost anything.

Sincerely as djie a few days ago in another post I think that these printers with a little more time will change many things in our hobby and in other fields.

Let me tell you.

Model downloaded from Grabcad great page, I am very sorry not to be able to say who is the author of the model and I apologize from here, because I downloaded it and then when looking for the author I discovered that there were a lot of authors with this same model.

On the original model, touch up some parts to improve the settings and then calculate the appropriate size to be able to print all the parts.

Anycubic photon s printer

Transparent opaque green and white resin

The green one for the smallest pieces and the white one for the big ones.

A while of adjusting some sandpaper and glue a coat of paint and go.

Now I am preparing the second version and I hope to make it functional.

I am at your disposal to exchange ideas, models and exchange experiences.

REGARDS

That's a fine engine, Carmelo! I have zero experience with that type of printer - heck, I barely understand my standard home-type printer/copier/fax anyway! However, I see how these 3D printers are evolving into extremely useful tools - even for the home, not professional user. And I'll wager that even though they're not cheap, the price has decreased compared to their usefulness.

Bravo!

That's really impressive Carmelo. What is the approximate size? As you said, this really offers a lot of opportunity to create special items.

approximately 15cm high by 10cm long.

I could do it a little more, so big if I modify the way of printing but then the printing process is very long.

This type of printers on the x-axis and work fast the Z axis is what makes the process more elongated.

In this model most of the pieces have taken about 2 hours per set and the cylinder liners about 4 hours approx

Outstanding result, sir...well done.

Brilliant work!

I have an Anycubic Photon myself and it is a fantastic tool.

Now that right there is a "market disruptor," sir, in more ways than one! Incredible workmanship!

Very impressive.

Would that be a lever in the middle? I just want to pull it and gnnnnn!, There it goes. Fabulous piece of machine. Not into engines at all but it is what they provided for us in terms of power and usability that is interesting. What is next for your printer?

Another steam engine, this one of the horizontal type and I will try to change the crankshaft axes for a metal as well as some small parts to try to make it functional

REGARDS

Very cool!

WOW :-O great. I want to do the same in the future in order to recreate a diorama of a hydraulic or power station from the early 20th.

Agree with you, 3D printing will change a lot our hobby.

Did you already try to Fusion 360? Great CAD, quite easy to model, full of tutorials and free for modelers.

I have been using rhinoceros for some time and something with solid.

3D programs are a personal theme and you have to adapt to the workflow when you have become accustomed to one, it is difficult to change.

But I'll look at the Fusion 360. Thank you very much