Another Mustang Story.

Making a wooden mold was easy to make, so I could "vac-u-form" my windscreen, canopy and half-round side windows. As a child of around 6 year old, we neighborhood boys all had "pen-knives" and use to sit around an "widdle" on sticks. We used the word WIDDLE instead of CUTTING when we were that age. With this childhood experience it was easy for a 60+ years old person like me to cut out and sand a piece of wood to the size I had drawn on some paper. It looks like I coated the wood with some clear varnish or maybe I just used some Future Floor Wax. It's hard for me to remember today what I actually did as it has been 26 years ago.

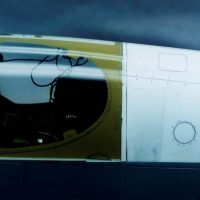

Little by little I cut and "dry-fit" my wooden parts to the model and when I think I got it right, I made some clear "vac" window parts and "dry-fit" them to the model. I forgot how many time's I did this until I got perfect parts but that was my goal. Somewhere along this process I decided to make the finished canopy open just like on the real P-51B, so it was "cut and fit until it fit."

I sent photos to the client so I could get my next payment and the "go-ahead" to continue the building process. Enjoy...Rodney...

Even knowing it is large scale, it is extremely well done! Thank you for sharing these builds Rodney, I enjoy them all!

Nice process, Rodney!

I might be tempted to do the same, as I have a couple of mising transparencies I have to somehow fabricate.

This is a real good fit.

Well done, Rodney.

TO: Erik , Spiros & John:

Remember...if I can do it when I was a "novice" modeler, you can do it as an "intermediate" to a "master" modeler like you "guy's" are now. Wait until I post my bare metal 1/48 scale P-80 Shooting Star, as it will blow you away.

Cheer's again.