Updating an old Iwata HP-B

Hi Everyone!

I had only little little time to build anything and this post isn't about finished plastic either. I'm an airbrush guy and fond of airbrushing in general and - as I suppose happens frequently such people - I had and I have several airbrush guns, more than I need and less then I want :D. I tried several brands and types through the years, buy and sell and repaired some for others so I can say that I have some experience with these tools. Later - If there's some interest occurs - I maybe make a forum topic about airbrushes, airbrushing, tests/comparisons, and for know-how echange. But this time I like to share with You my attempt to update my old Iwata HP-B that I bought used and.

I like Iwatas (who don't? - maybe not for their prices) for their ruggedness, built quality and general simple and logic arrangement. I already have a HP-CH (a great gun) and when I saw this advertised used with it's 0,2mm nozzle arrrangement I felt that I needit 🙂 . It was quite a bargain for not much more than a chinese AB-180 but beleive me the difference is huge! This is an old version of their Hi-Line B As Iwata announced their rewampeb Hi-Line serie the price of these old guns declined delightfully. The old and the new are equal performance wise but the new have some alterations that make maintenance and cleanin easier (+pre set/ cut out handle which is nice but not necessary) and the significant change using PTFE (commonly say teflon) seals to deal with organic solvents. The great nature of Iwatas that their head system doesn't use any sealy as the precise elaboration make them unnecessary. The Hi-Line serie use only one 🙂 seal that relates to paint camber and this is the needle packing seal so I thought that I buy this gun, clean it, chech it and try to replace that sole seal and I have a modern, bullet proof detail airbrush.

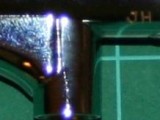

As I said i bought it cheap. It was in generally good (hardly used) but somehow neglected shape so complete dismantling and cleaning was obvious. I stripped it down completely (minus the air valve which worked good) removed all rubber or soft parts and soaked it into some stronger cleaning materials - normally I strongly not recommend this to anyone but this gun as I saw was put aside uncleaned for a long time. I searched through my spare parts and found a PTFE seal which I bought when I renewed my friends chinese airbrush and the size was a perfect match. As You can see on the pics I measured it to the old rubber "O" ring. If You want to play with needle packing You have to have a special screw-driver You can see on the pics. This particular tool have a needle that help align the seal with the packing screw. An important hint about teflon seals: they are compressable and dimensionally stable but not elastic either. If You overtighten a rubber "O" ring that's not a problen only have to losen the screw a little bit and that's all. If You overtighten a PTFE seal that might be a problem as - said previously - they dimensionally stable and dont return of their original shape when loosening that screw. The solution is that Ypu have to tighten the needle packingscrew step by step in small increments checking the resistance of the needle. This may means some assembly and disassembly but woth the effort as PTFE seal installed correctly lasts long. The goal here is that You have to tighten the screw that point when the needle packing seal tight enough around the needle that paint can't overflow back to the valve housing but the needle itself move freely or little resistance. You have to feel it, there's no any exact measuring here. I hope this help if someone faces similar issues or just interesting how it's like an old Iwata dismantled 🙂 Cheers!

Nice article, lots of good info.

I too have an Iwata HP-BD that has served me well for years. But I have to admit, my all time favorite is my trusty Badger 200. I bought this baby over 15 years ago, have sent it back to Badger twice and each time they returned it within a week, as good as new. Its not quit up to doing some of the delicate work the Iwata can do, but that's why I own both.

Hi! I think airbrush is a very personal tool as a car - matter of taste, feel and preferences. I have favourite and least favourite guns too. I never have a Badger - as I'm in Europe it's not a surprise - but I heard lot of good about them and I learnt that they begun the making ABs for hobby business.

Interesting article, on a very important aspect of modelling. I bought a new compressor and two dual action airbrushes, as a set from a shop here in Australia that sells mostly european goods and groceries. The compressor is great complete with water trap and the airbrushes are no name brands, but look like copies of the Badgers. I have a trusty old badger which I would like to use still, but the air hose won't fit the new compressor connection, as it has a smaller and much finer thread. Can you get adaptors for this?

Thank You! The most important thing for airbrushing is the decent air supply. Agood compressor is always a sound investment. I owe two, a piston type with collector tank (I bought as a backup) but I normally use a home-build silent type one that has benn serving me for over 15 years now. I suspect that You have far east manufactured compressor (my backup compressor is chinese made one - suprisingly good) and they use Iwata style connectors for some reason. Onebay You can find easily any type of connection converter couplings. I use a fast connector arrengement for all of my ABs and like them very much. http://www.ebay.com/itm/AIRBRUSH-QUICK-RELEASE-COUPLING-BODY-BADGER-AIRBRUSH-/261198092617?hash=item3cd09e9949:g:3tMAAOxy4fVS~M9O or http://www.ebay.com/itm/Airbrush-Adapter-Connecter-1-8-for-Badger-WD58-/161503133766?hash=item259a564046:g:r8UAAOSwj0NUevAA

Greetings Gabor,

I just found my old HP-B airbrush buried under a pile of rusty bolts and nuts in an old drawer. It has dried, very hard to remove paint on the body as well as the inside, so I think I need to soak it in something strong for a long time. What solution do you recommend? I just now used acetone on the outside and removed almost all the dried paint, but I need to do something about the inside. I couldn't believe I found it! The Lord helped me for sure!

Hi Harry!

It depends on how deep do you want to disassemble your airbrush. The body and the metal tarts are all top quality parts in an Iwata and tolerates well even stronger cleaning materials. The "soft parts" - O rings and seals - however are quite sensitive. In the old guns they made from Viton (synthetic rubber) and dissolve when they soaked into acetone for example. When I need to deep clean an airbrush I always disassemble it fully. Nowadays I use a special cleaning material which developed for paint removing - I buy it a hardware store. The most important thing is that use such material that doesn't harm the copper (the gun made from copper mostly) and the chrome plating. Another factor is when you soak an airbrush body into thinner, that you have to wash out thoroughly when you finished the cleaning, because the old paint particles can enter into the air channels. I use ultrasonic cleaner and a syringe for this. I hope this helps a bit.